Composite structure capable of retarding magnesium-alloy degradation under coating by silk fibroin

A technology of silk fibroin and composite structure, applied in coating, medical science, prosthesis, etc., can solve problems such as inability to carry out application, and achieve the effect of being beneficial to repair and reducing the degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

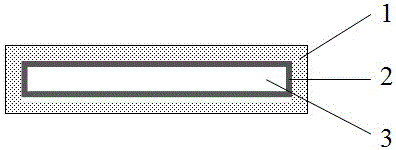

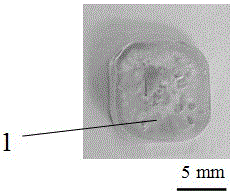

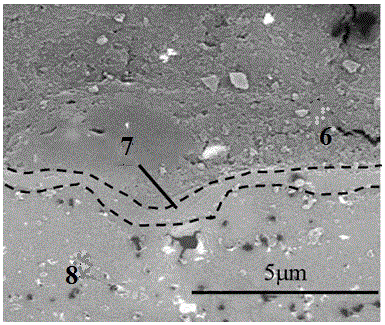

[0026] Such as figure 1 and 2 As shown, the composite structure of the present invention that can delay the degradation of magnesium alloys under the coating of silk fibroin is sequentially composed of magnesium alloy matrix 3, surface modification layer 2 and silk fibroin film 1 from the inside to the outside, wherein:

[0027] The magnesium alloy substrate 3 is a magnesium sheet with a side length of 10 mm and a thickness of 2 mm, which is a biomedical Mg-Zn-Ca alloy, and the element composition and content distribution are Zn: 1-2%, Ca: 0.2-1% , Al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com