Ultrasonic mold casting method for alloy steel

An ultrasonic and alloy steel technology, which is applied in the field of ultrasonic die casting of alloy steel, can solve problems such as the inability to introduce ultrasonic waves into high-temperature steel melts, the inability to achieve long-term ultrasonic effects, and the destruction of ceramic materials, so as to achieve the reduction of micro-porosity defects, The effect of reducing attenuation and preventing shattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

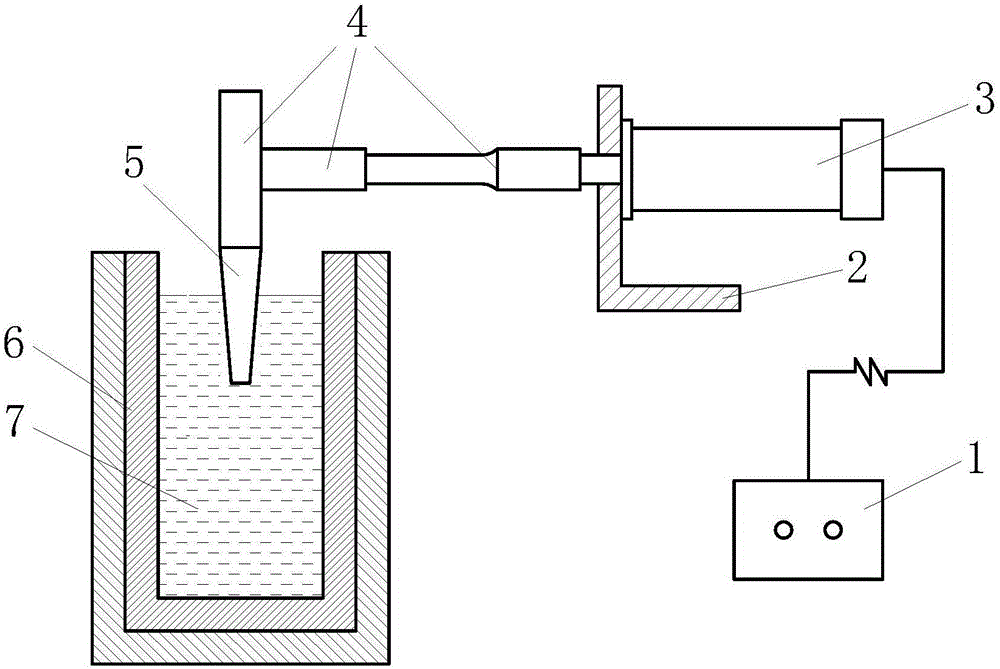

[0023] Pour the 35CrMo molten steel that has been kept warm for a period of time after slag removal and deoxidation treatment into the mold 6, and cover the surface of the molten steel with thermal insulation materials, then turn on the ultrasonic power supply 1, adjust the height of the bracket 2 of the ultrasonic device, and put the preheated ultrasonic The tool head 5 is inserted into the molten steel 7 for ultrasonic treatment. The depth of the ultrasonic tool head inserted into the center of the molten pool is 20mm. Adjust the power of the ultrasonic generator, and use ultrasonic waves with a frequency of 25.5KHz and a power of 500W for processing. The ultrasonic treatment is stopped before the molten steel is completely solidified, and the ingot is left to stand and air-cooled to obtain an ultrasonic molded steel ingot. The high temperature resistant ceramic tool head 5 of the ultrasonic generator used has a length of 190mm and a truncated cone shape with a bottom diame...

Embodiment 2

[0025] Pour the 35CrMo molten steel that has been kept warm for a period of time after slag removal and deoxidation treatment into the mold 6, and cover the surface of the molten steel with thermal insulation materials, then turn on the ultrasonic power supply 1, adjust the height of the bracket 2 of the ultrasonic device, and put the preheated ultrasonic The tool head 5 is inserted into the molten steel 7 for ultrasonic treatment. The depth of the ultrasonic tool head inserted into the center of the molten pool is 50mm. Adjust the power of the ultrasonic generator, and use ultrasonic waves with a frequency of 25KHz and a power of 1000W for processing. The ultrasonic treatment is stopped before the molten steel is completely solidified, and the ingot is left to stand and air-cooled to obtain an ultrasonic molded steel ingot. The high temperature resistant ceramic tool head 5 of the ultrasonic generator used has a length of 185mm and a truncated cone shape with a bottom diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

| Top diameter | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com