Tissue packaging machine for hygienic materials

A hygienic material and packaging machine technology, applied in paper product packaging, packaging, folding thin materials, etc., can solve the problems of secondary pollution of paper towels becoming waste products, affecting the smooth progress of processing, shortening the service life of equipment, etc., to reduce secondary pollution Effects of secondary pollution, accelerated production schedule, and reduced number of inputs and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

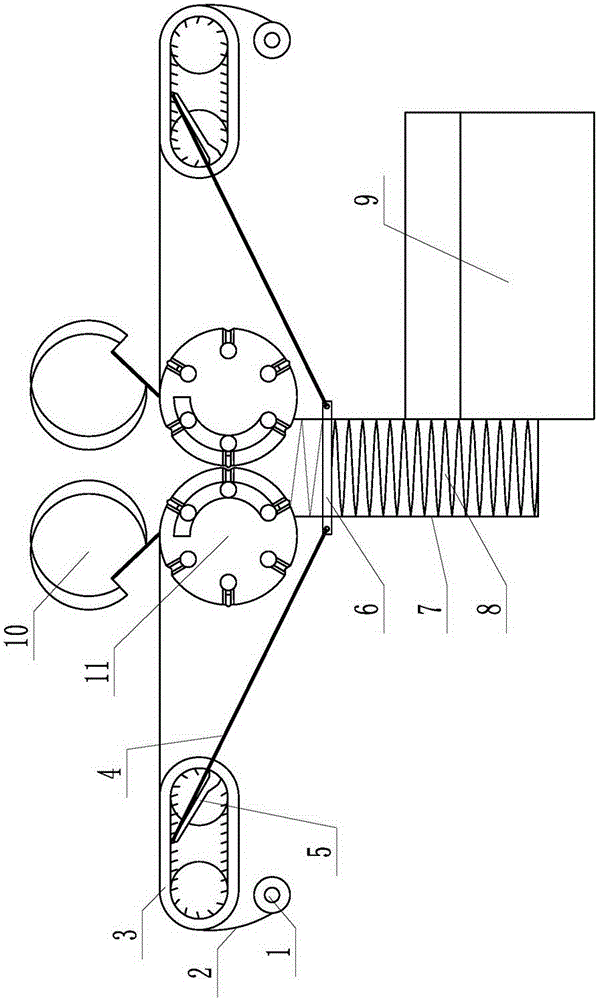

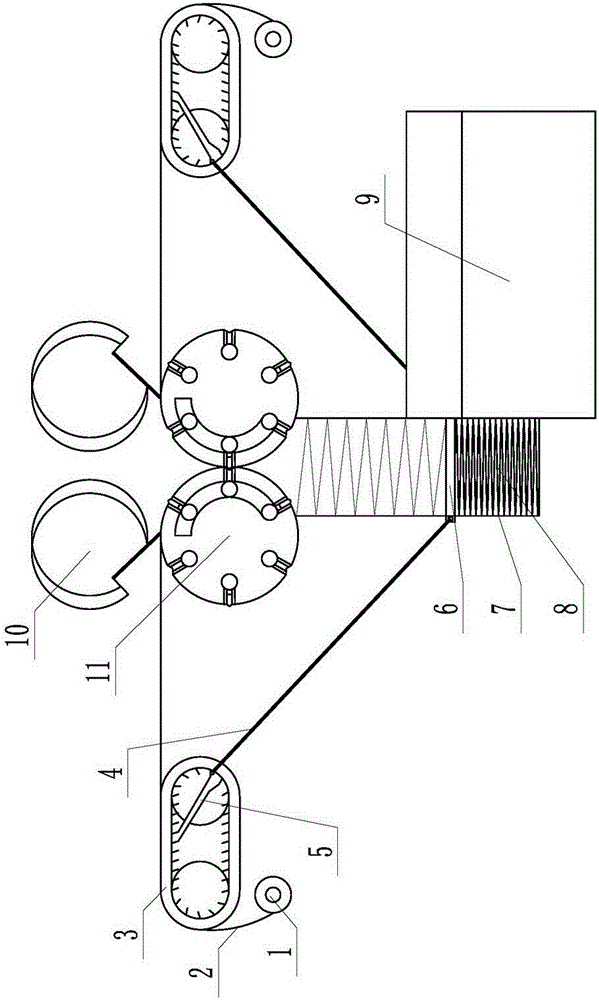

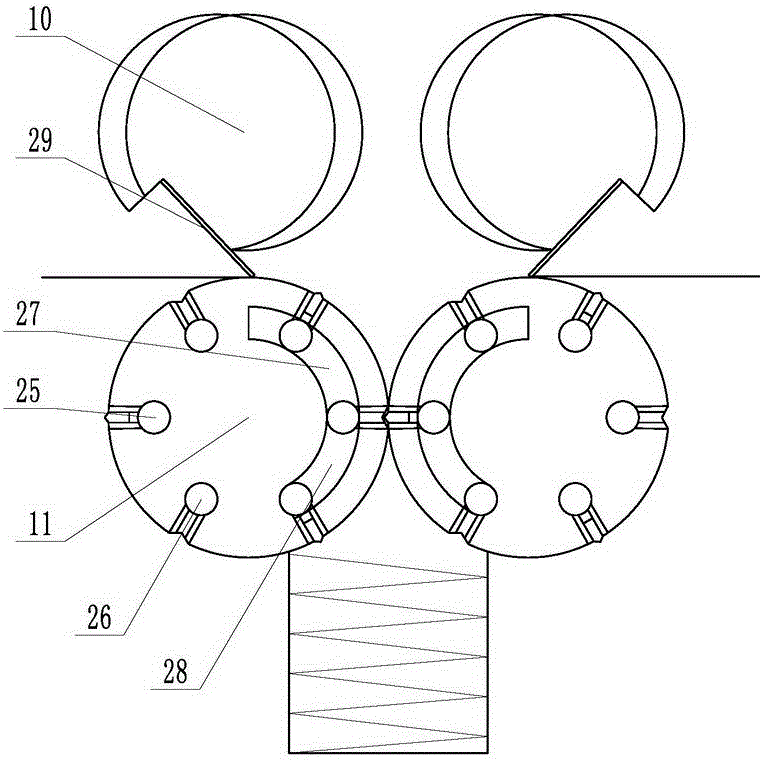

[0038] Embodiment 1: According to Figure 1 to Figure 10 As shown, the present invention includes a paper-feeding mechanism, a folding mechanism and a packaging mechanism. The paper-feeding mechanism includes a paper-feeding belt 3. There are a plurality of teeth 18 protruding obliquely from both sides of the paper-feeding belt 3 in the same direction. The paper-feeding mechanism has a built-in Both ends are respectively connected to the chute 5 on the upper and lower sides of the paper feeding belt 3, and a long rod 4 is slidably connected in the chute 5;

[0039] The folding mechanism includes two sets of symmetrical paper cutting rollers and 10 folding rollers 11;

[0040] Below the folding mechanism, there is an origami groove 7 for holding the folded paper towel 2. The origami groove 7 is divided into upper and lower parts by the holding plate 6. The holding plate 6 slides up and down on the origami groove 7, and the two ends of the holding plate 6 are extended. Out of t...

Embodiment 2

[0049] Embodiment 2: On the basis of Embodiment 1, the middle section of the first connecting rod 38 is provided with a stopper 39, and the right end of the first connecting rod 38 is sleeved with a sliding sleeve 41 connected with the second connecting rod 43. The blocks 39 are connected through the second spring 40 , and the right side of the sliding sleeve 41 is fixed on the first connecting rod 38 through the nut 42 .

[0050] During normal use, the motor 16 drives the second connecting rod 43 to swing, the second connecting rod 43 drives the first connecting rod 38 to swing in conjunction with the swing rod 37, and the ratchet 45 drives the ratchet 36 to rotate normally; 34, the conveying roller 35 cannot drive the conveyor belt 15 to advance, and now the motor still drives the second connecting rod 43 to swing, and the second connecting rod 43 drives the sliding sleeve 41 to press the second spring 40 to the left, and the first connecting rod 38 and The position of the f...

Embodiment 3

[0052] Embodiment 3: On the basis of Embodiment 1, the overload control device includes a shaft 49 fixed through a shaft sleeve 53, the shaft 49 can slide in the shaft sleeve 53, and a protrusion 51 is protruded in the middle of the shaft 49. 49 The right side of the upper bump 51 is sleeved with a third spring 52 connecting the bump 51 and the bushing 53, forming a structure in which the third spring 52 pushes the shaft 49 to the left, and the right side of the shaft 49 is fixed with a micro switch 50, forming the structure that the motor 16 is turned off after the shaft rod 49 touches the micro switch 50.

[0053] When overloaded, the fifth connecting rod 44 pushes against the shaft rod 49, so that the shaft rod 49 moves to the right and touches the electric shock of the micro switch 50, thereby cutting off the power supply of the motor 16. During normal operation, the third spring 52 keeps the shaft rod 49 Push against the left side of the shaft sleeve 53 so that it leaves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com