System for processing phosphorite and application thereof

A phosphate rock and furnace cavity technology, applied in the direction of phosphate material processing, phosphoric acid, phosphorus oxyacid, etc., can solve the problems of difficult realization, high requirements for pelletizing process, and difficult control, so as to save operating costs and guarantee products. The effect of quality and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] Utilize the system for processing phosphate rock of the embodiment of the present invention to process phosphate rock to prepare phosphoric acid, and the process of processing is as follows Figure 5 As shown, the specific steps are as follows:

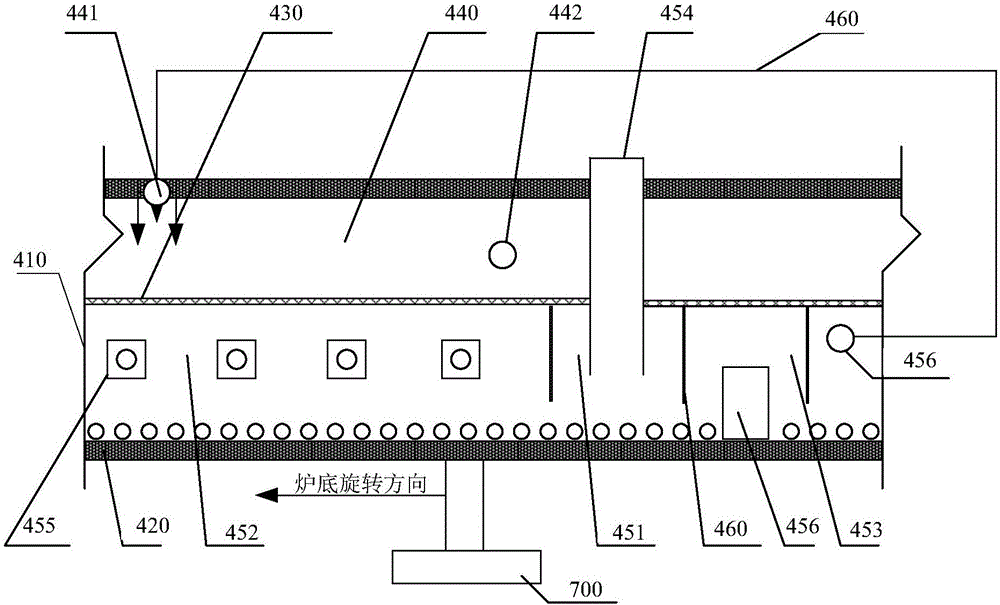

[0106] Mix the phosphate rock that is ground to 200 mesh and account for more than 50% with semi-coke, silica and binder according to a certain ratio, and use a disc pelletizer to make pellets, of which P 2 o 5 The grade is 21.5%, the amount of semi-coke added is 1 times of the theoretical requirement, the amount of silica added is 12% of the weight of phosphate rock, the binder is selected from sodium-based raw materials and bentonite, and then the grate is used at 100-200°C. Dry the prepared carbon-containing pellets until the moisture content is less than 2%. The dried carbon-containing pellets are placed in the lower chamber of the rotary hearth furnace for preheating and reduction. The reduction temperature is 1300°C, and...

Embodiment 2

[0108] Utilize the system for processing phosphate rock of the embodiment of the present invention to process phosphate rock to prepare phosphoric acid, and the process of processing is as follows Figure 5 As shown, the specific steps are as follows:

[0109] Mix the phosphate rock crushed to -2mm and account for more than 75% with lignite, silica and binder according to a certain proportion and press the ball with a ball press machine, where P 2 o 5 The grade is 28%, the addition amount of lignite is 1.3 times of the theoretical requirement, the addition amount of silica is 2% of the weight of phosphate rock, the binder is liquid binder, and the pressed pellets are dried until the water content is ~4%. The lower chamber of the rotary hearth furnace is preheated and reduced, the reduction temperature is 1380°C, the rotation speed of the rotary hearth furnace is controlled at 65min / r, and the included angle of the ring of the reduction chamber is 270°C. P-containing 4 The g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com