A kind of nano calcium silicate ceramic formula friction material and its preparation method

A technology of nano-calcium silicate and friction materials, applied in friction linings, ceramic molding machines, chemical instruments and methods, etc., can solve problems such as copper dust pollution and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

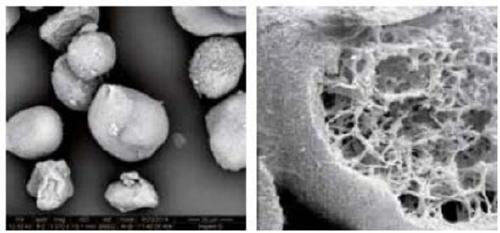

Image

Examples

Embodiment 1

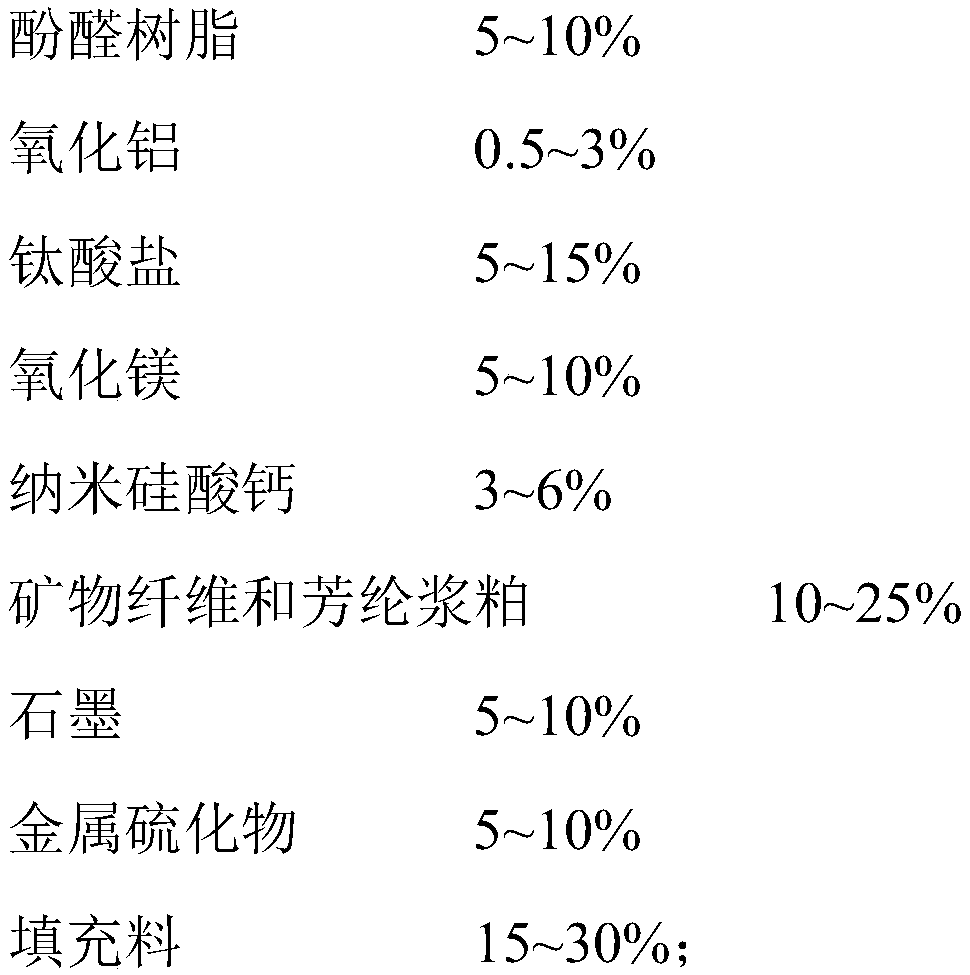

[0019] A nano-calcium silicate ceramic formula friction material in this embodiment is composed of the following components in terms of weight percentage:

[0020]

[0021] In this embodiment, mineral fibers include aluminum silicate fiber and basalt fiber, wherein aluminum silicate fiber accounts for 8% of the total weight of the friction material, basalt fiber accounts for 9% of the total weight of the friction material, and aramid pulp accounts for the total weight of the friction material 3%.

[0022] Further, the filler in this embodiment may be one or a combination of barium sulfate and calcium carbonate.

[0023] A preparation method of the above-mentioned nano-calcium silicate ceramic formula friction material, comprising the following steps:

[0024] (1) Mixing, the mixing is completed in two stages. In the first stage, fillers, mineral fibers and a small amount of graphite are added, mixed and dispersed; in the second stage, the remaining component materials are ...

Embodiment 2

[0029] A nano-calcium silicate ceramic formula friction material in this embodiment is composed of the following components in terms of weight percentage:

[0030]

[0031] In this embodiment, mineral fibers include aluminum silicate fiber and basalt fiber, wherein aluminum silicate fiber accounts for 9% of the total weight of the friction material, basalt fiber accounts for 10% of the total weight of the friction material, and aramid pulp accounts for the total weight of the friction material 5%.

[0032] Further, the filler in this embodiment may be one or a combination of barium sulfate and calcium carbonate.

[0033] A preparation method of the above-mentioned nano-calcium silicate ceramic formula friction material, comprising the following steps:

[0034] (1) Mixing, the mixing is completed in two stages. In the first stage, fillers, mineral fibers and a small amount of graphite are added, mixed and dispersed; in the second stage, the remaining component materials are...

Embodiment 3

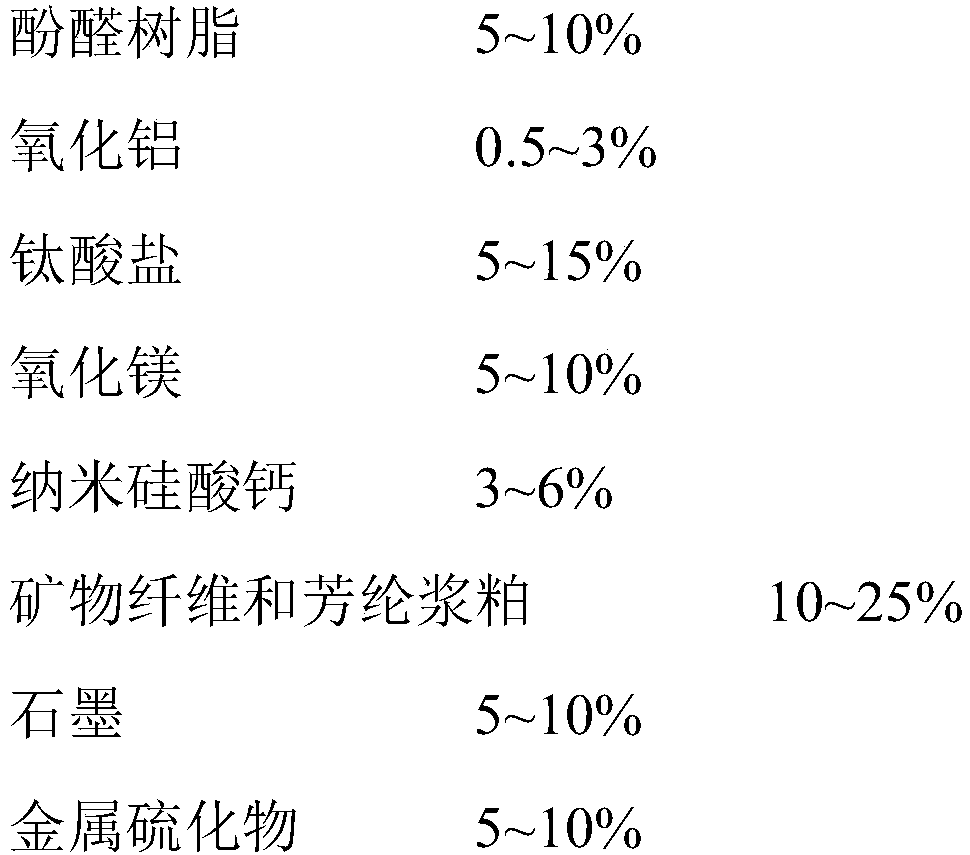

[0039] A nano-calcium silicate ceramic formula friction material in this embodiment is composed of the following components in terms of weight percentage:

[0040]

[0041] In this embodiment, the mineral fibers include aluminum silicate fiber, basalt fiber and aramid pulp, wherein aluminum silicate fiber accounts for 7.5% of the total weight of the friction material, basalt fiber accounts for 8.5% of the total weight of the friction material, and aramid pulp 4% of the total weight of the friction material.

[0042] Further, the filler in this embodiment may be one or a combination of barium sulfate and calcium carbonate.

[0043] A method for preparing the above-mentioned nano-calcium silicate ceramic formula friction material, comprising the following steps:

[0044] (1) Mixing, the mixing is completed in two stages. In the first stage, fillers, mineral fibers and a small amount of graphite are added, mixed and dispersed; in the second stage, the remaining component mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com