Jacket material used for controllable grouting of shield tunnel underwater karst, and preparation method thereof

A technology of shield tunneling and preparation method, applied in the field of geotechnical engineering foundation treatment grouting, can solve the problems of poor longitudinal sealing effect, difficult setting time of casing, difficult control of axial diffusion, etc., and achieves adjustable strength and condensation. The time can be adjusted to improve the effect of anti-seepage reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16

[0034] The casing materials of Examples 1-16 are mainly composed of clay syrup, cement, water and fly ash. The specific gravity of the clay syrup is controlled between 1.20 and 1.35, and the mass ratio of cement and fly ash is 1:1 to 1.5. :1. The raw material ratios of the casing materials of Examples 1-16 are shown in Table 1.

[0035] Table 1 includes 16 sets of uniformly designed ratios (Examples 1-16), in which the original pulps are all 6L, the proportions of the 1-4 sets of syrups are 1.20, the proportions of the 1-4 sets are 1.25, and the proportions of the 9-12 sets are 1.30, the proportion of 13-16 groups of puree is 1.35, and the data of each component in the table is calculated in the mass unit kg.

[0036] Table 1 Evenly design the ratio of each group

[0037] Example12345678910111213141516 Puree4.84.84.84.85.05.05.05.05.25.25.25.28.18.18.18.1 cement0.540.801.091.340.800.541.341.091.091.340.540.802.001.601.200.80 Fly ash 0.540.801.091.340.800.541.341.091.091.340....

Embodiment 17

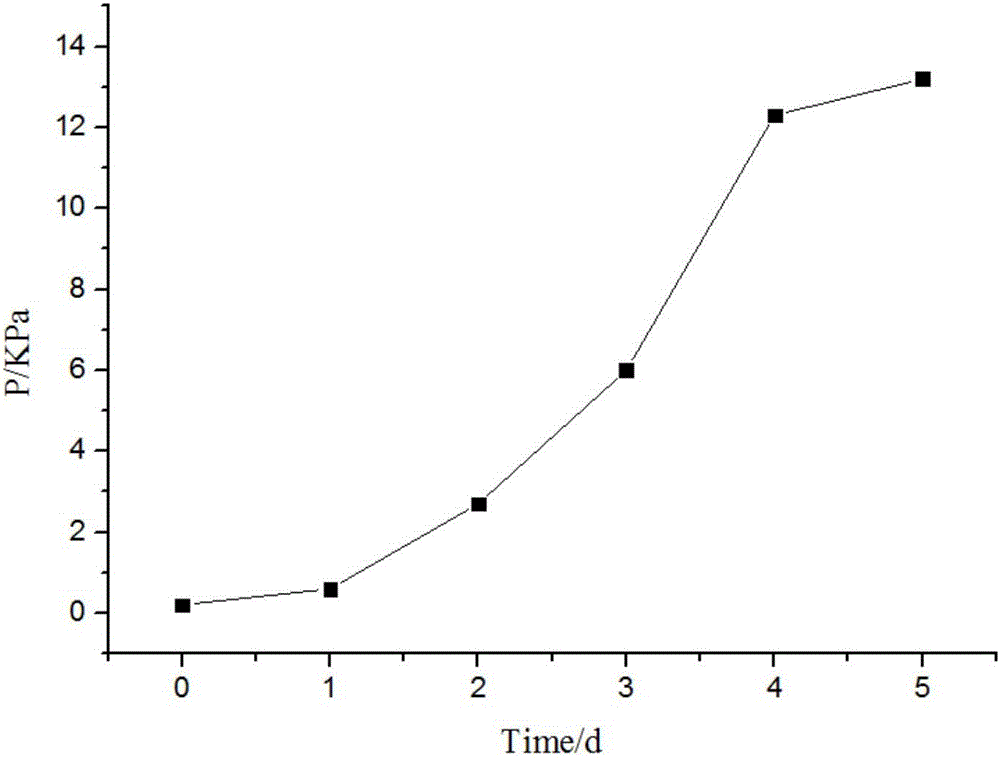

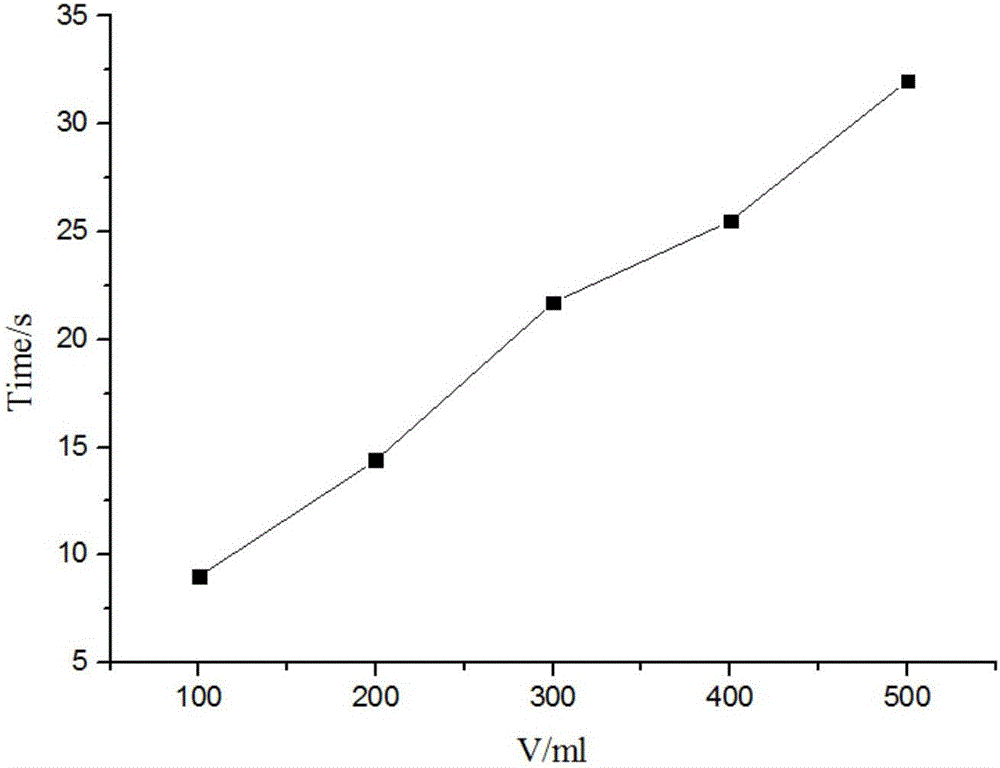

[0042] The test results (engineering indicators) in Table 2 are used for data analysis, and the regression relationship between each factor and the specific gravity, plastic strength and compressive strength of the casing material is established by using IBM-SPSS software. Suppose the quality of the original slurry is X1, the quality of cement is X2, the quality of fly ash is X3, the specific gravity of the shell material is G, the 3d compressive strength is P3, the 7d compressive strength is P7, and the fluidity is L. The following relationship (regression function) can be obtained:

[0043]

[0044]

[0045]

[0046]

[0047] The construction site of a shield tunnel underwater karst treatment needs to be equipped with casing material performance of 1.35≤G≤1.60, 130mm≤L≤190mm, P3≤0.3MPa, P7≤0.6MPa. Through the above regression function, using the matlab optimization toolbox fgoalattain function to establish a linear multi-objective mathematical model, the ratio of the slurry can...

Embodiment 18

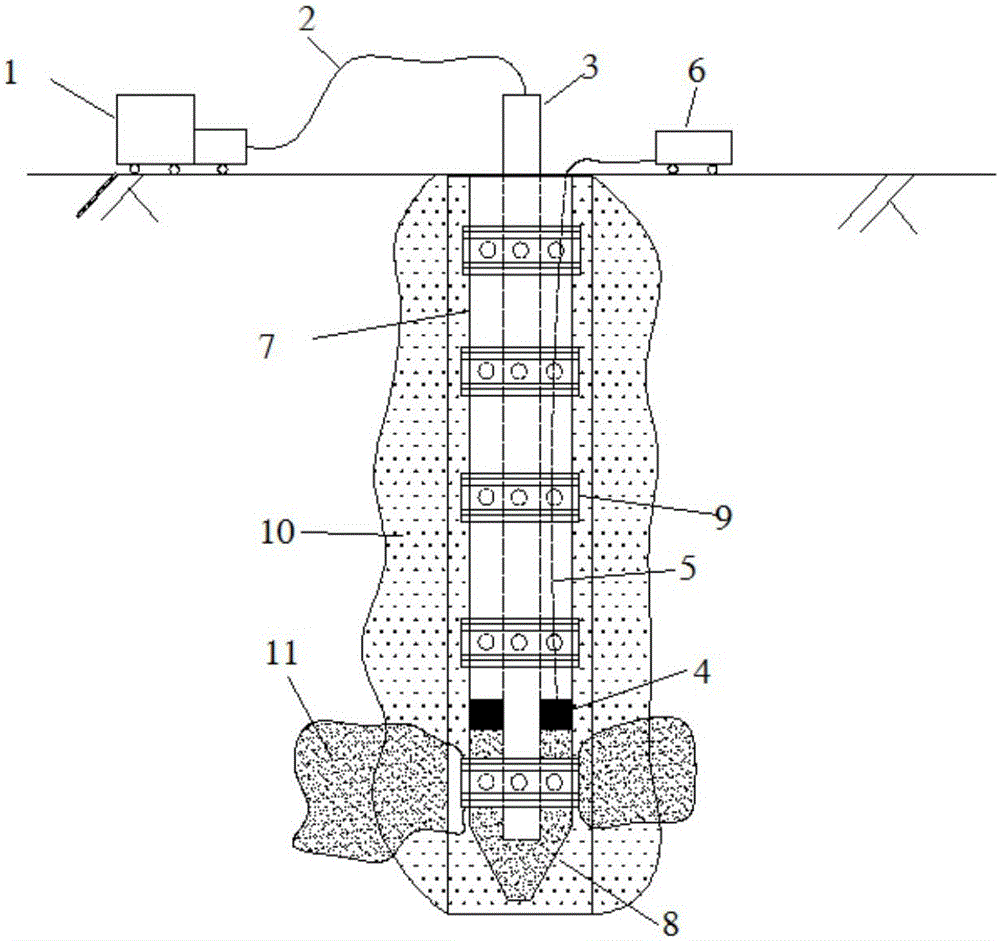

[0051] The preparation method of the casing material for the shield tunnel underwater karst controllable grouting of this embodiment includes the following steps:

[0052] S1: Measure the engineering indicators required for casing materials through indoor orthogonal experiments;

[0053] S2: Regression of engineering indicators (here engineering indicators mainly refer to the requirements of construction and grouting effects, such as: pumpability, setting time, fluidity, plastic strength, compressive strength, etc. and stone body strength, impermeability, etc.) Analyze, get the regression curve between each component and engineering index. Regression analysis includes: multiple regression analysis of engineering indicators, and the regression model adopts the second-order mixture specification polynomial.

[0054] S3: According to the actual needs of the project, the specific gravity of the clay slurry, the quality of fly ash and the quality of cement are determined by establishing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com