Clothianidin granule and preparing method thereof

The technology of clothianidin and granules, which is applied in the field of chemical technology, can solve the problems of short duration of effect, increased drug cost, increased use of pesticides, etc., and achieves the advantages of reducing labor intensity, reducing the number of spraying and simple product process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

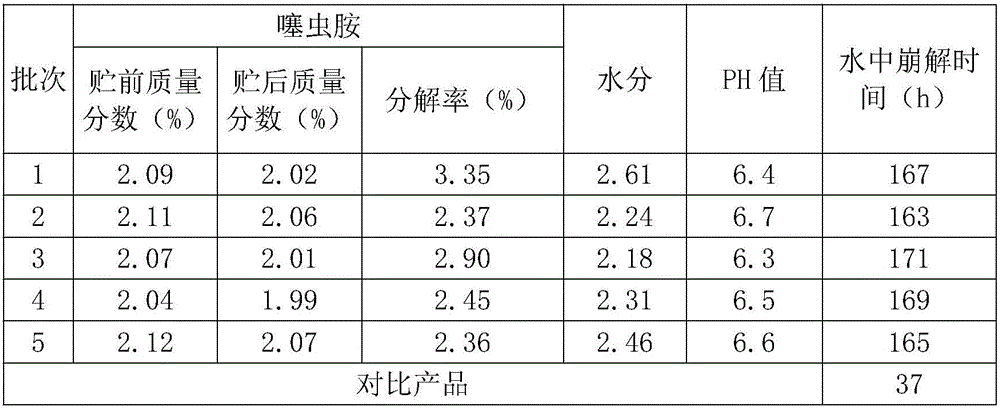

[0027] Example 1, 2% clothianidin granules.

[0028] The formulation of 2% clothianidin granules:

[0029] Clothianidin 2%, Paraffin 2%, Vinyl Resin 4%, Gelatinized Starch 3%, Xanthan Gum 2%, Carboxymethyl Cellulose 2%, Polyvinylpyrrolidone 0.6%, Reactive Red 2%, Kaolin quantity.

[0030] The preparation method of 2% clothianidin granules:

[0031] Step 1, take clothianidin 1%, gelatinized starch 1.5%, xanthan gum 1%, carboxymethyl cellulose 1%, polyvinylpyrrolidone 0.3%, reactive red 0.8%, kaolin 41.2%, after mixing uniformly Airflow pulverization, granules are formed by a drum, and the obtained ①;

[0032] Step 2, take 1% of paraffin wax and 1% of vinyl resin, dissolve and mix them at high temperature, pour them into a drum and coat them evenly with ① to obtain ②;

[0033] Step 3, take clothianidin 1%, gelatinized starch 1.5%, xanthan gum 1%, carboxymethyl cellulose 1%, polyvinylpyrrolidone 0.3%, reactive red 1.2%, kaolin 41.2%, after mixing uniformly Airflow crushing, ...

Embodiment 2

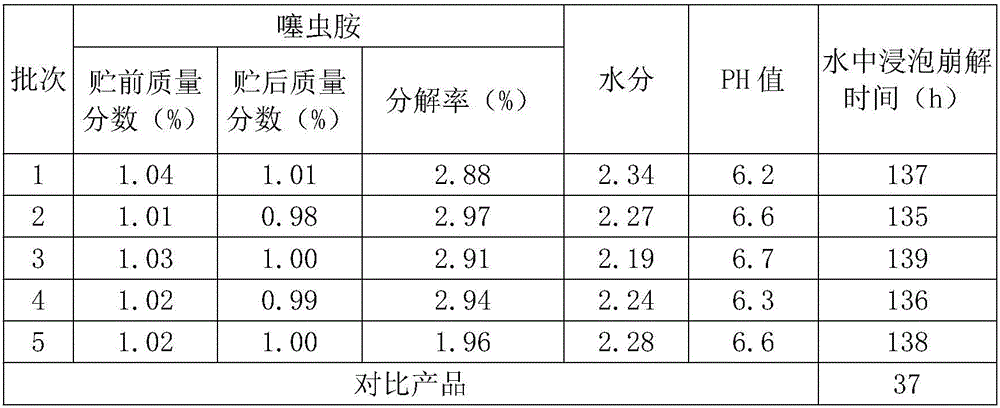

[0039] Example 2, 1% clothianidin granules.

[0040] The formula of 1% clothianidin granules: clothianidin 1%, paraffin 3%, gelatin 3%, xanthan gum 2%, methylcellulose 2%, corn starch 3%, reactive red 1.6%, kaolin quantity.

[0041] 1% clothianidin granule preparation method:

[0042] Step 1, mix 0.5% clothianidin, 1% xanthan gum, 1% methyl cellulose, 1.5% cornstarch, 0.8% reactive red, and 43.7% kaolin evenly and then pulverize by airflow, and form granules by rollers to produce got ①;

[0043] Step 2, dissolving and mixing 1.5% paraffin and 1% gelatin at high temperature, pouring it into a drum and coating it evenly with ① to obtain ②;

[0044] Step 3: Mix 0.5% clothianidin, 1% xanthan gum, 1% methylcellulose, 1.5% cornstarch, 0.8% reactive red, 43.7% kaolin, and then pulverize by airflow, pour into the drum and mix with ② Uniform coating, obtained ③;

[0045] Step 4, dissolve and mix 1.5% paraffin and 2% gelatin at high temperature, pour into a drum and coat evenly wit...

Embodiment 3

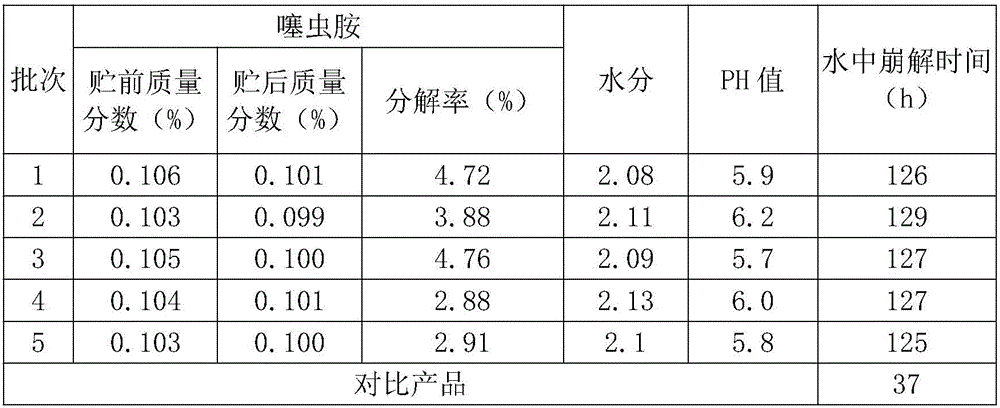

[0050] Embodiment 3, 0.1% clothianidin granule (mixture of medicine and fertilizer).

[0051] The formula of 0.1% clothianidin granule (drug fertilizer mixture): 0.1% clothianidin, 2% vinyl resin, 1% paraffin, 2% xanthan gum, 3% sticky powder, 1.5% reactive red, granule compound Fat margin.

[0052] The preparation method of 0.1% clothianidin granules:

[0053] Step 1: Take 0.1% clothianidin, 2% xanthan gum, 3% sticky powder, and 1.5% reactive red, mix them evenly, crush them by air flow, mix them with granule compound fertilizer, and pass them through a drum to form granules, thus obtaining ①;

[0054] Step 2, take 2% polyvinyl alcohol, dissolve and mix at high temperature, pour into the drum and mix with ① to coat evenly;

[0055] Step 3, through drying equipment, 0.1% clothianidin granule (mixture of medicine and fertilizer) is obtained.

[0056] In order to verify the stability of product quality, we conducted a thermal storage stability test of the product: store it at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com