Method for preparing antibacterial membrane by N-succinyl-chitosan immobilized lysozyme

A technology of succinyl chitosan and lysozyme is applied in the field of preparing antibacterial film with modified chitosan solid-loaded lysozyme, and in the field of preparing antibacterial film with N-succinyl chitosan solid-loaded lysozyme, which can solve the problem of chitosan The problem of poor water solubility of sugar, etc., achieves the effect of smooth surface, good antibacterial property, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

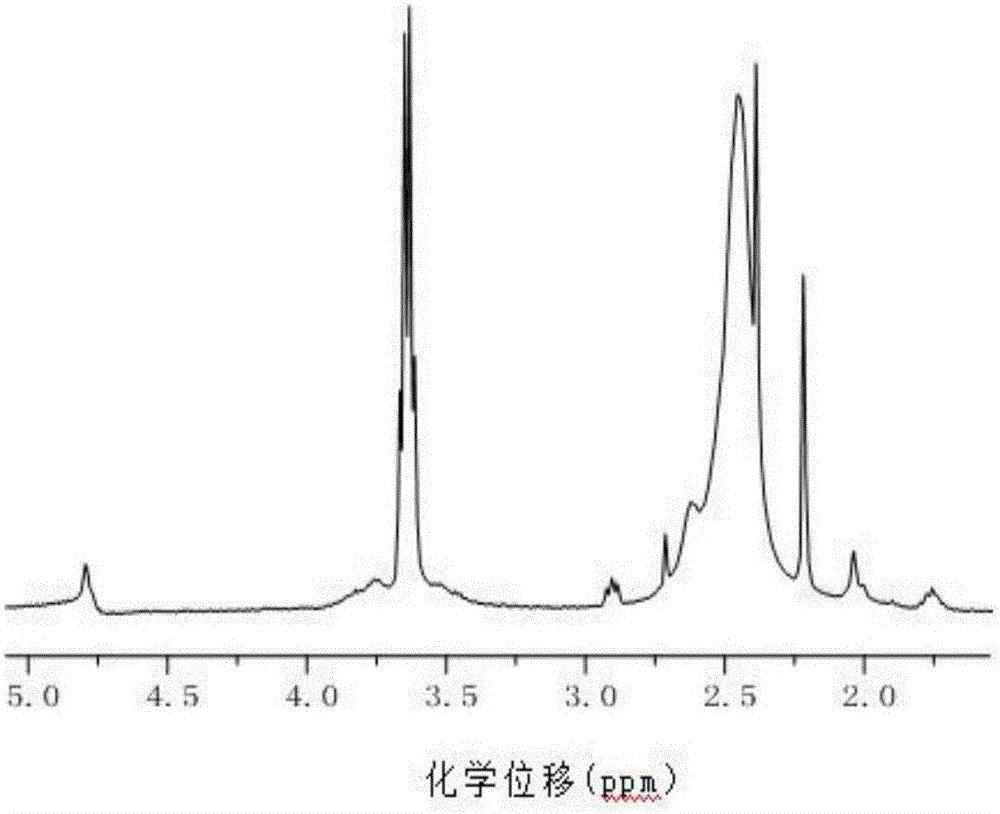

[0025] Weigh 3g of chitosan powder and add it to 63mL of DMSO for mixing, slowly add 7.5g of succinic anhydride, react at 60°C for 7h, filter the solution, dissolve the precipitate in ethanol at room temperature, and react at room temperature for 2h. Adjust the pH of the solution to 10 with 1M NaOH, filter, and dissolve the precipitate in 140 mL of distilled water. Then add 420 mL of acetone, wash the precipitate three times with ethanol and acetone respectively, and dry the obtained product under vacuum condition at 50° C. for 24 h.

[0026] Weigh 1.0g NSC and dissolve it in 20mL citrate phosphate buffer with pH=5, add 0.02g EDC and NHS respectively, stir at room temperature for 2h, then add 0.05g lysozyme, stir for 2h, then add 7% glycerol , using the salivation method to make a film, dry it at 30°C for 7 hours, and peel off the film. Its antibacterial activity was tested by antibacterial test.

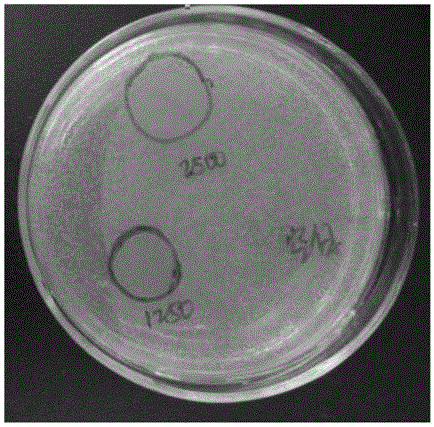

[0027] It was measured that the corresponding 2500ug / mL and 1250ug / mL lysozym...

Embodiment 2

[0029] Weigh 3g of chitosan powder and add it to 63mL of DMSO for mixing, slowly add 7.5g of succinic anhydride, react at 60°C for 7h, filter the solution, dissolve the precipitate in ethanol at room temperature, and react at room temperature for 2h. Adjust the pH of the solution to 10 with 1M NaOH, filter, and dissolve the precipitate in 140 mL of distilled water. Then add 420 mL of acetone, wash the precipitate three times with ethanol and acetone respectively, and dry the obtained product under vacuum condition at 50° C. for 24 h.

[0030] Weigh 1.0g NSC and dissolve it in 20mL citrate phosphate buffer with pH=6, add 0.02g EDC and NHS respectively, stir at room temperature for 2h, then add 0.05g lysozyme, stir for 2h, then add 7% glycerol , using the salivation method to make a film, dry it at 30°C for 7 hours, and peel off the film. Its antibacterial activity was tested by antibacterial test.

[0031] It was measured that the membrane solution with 2500ug / mL and 1250ug / m...

Embodiment 3

[0033] Weigh 3g of chitosan powder and add it to 63mL of DMSO for mixing, slowly add 7.5g of succinic anhydride, react at 60°C for 7h, filter the solution, dissolve the precipitate in ethanol at room temperature, and react at room temperature for 2h. Adjust the pH of the solution to 10 with 1M NaOH, filter, and dissolve the precipitate in 140 mL of distilled water. Then add 420 mL of acetone, wash the precipitate three times with ethanol and acetone respectively, and dry the obtained product under vacuum condition at 50° C. for 24 h.

[0034] Weigh 1.0g NSC and dissolve it in 20mL citrate phosphate buffer with pH=7, add 0.02g EDC and NHS respectively, stir at room temperature for 2h, then add 0.05g lysozyme, stir for 2h, then add 7% glycerol , using the salivation method to make a film, dry it at 30°C for 7 hours, and peel off the film. Its antibacterial activity was tested by antibacterial test.

[0035] It was measured that the membrane solution with the corresponding adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com