Method for preparing high-performance medical special rubber

A special rubber and high-performance technology, applied in the field of medical rubber, can solve problems such as poor corrosion resistance, reduced lifespan, and unsatisfactory antibacterial effect, so as to improve safety and quality assurance, increase service life, and be suitable for large-scale promotion and application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

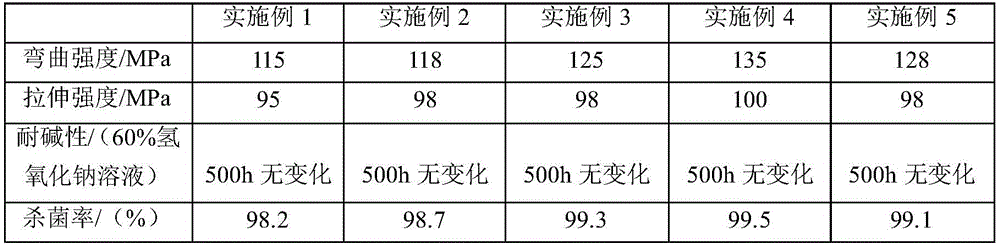

Examples

Embodiment 1

[0027] A preparation method of high-performance medical special rubber, comprising the steps of:

[0028] (1) 50 parts by weight of medical natural rubber materials with clean surface are placed in an ultraviolet irradiation reactor, the irradiation wavelength is 100nm, and the irradiation time is 60s to obtain surface-activated rubber;

[0029] (2) Prepare a 2wt% polyvinylpyrrolidone solution, crush the rubber obtained in step (1) and add it to the polyvinylpyrrolidone solution, heat to 60°C and stir for 20 minutes, then add 10 parts by weight of benzalkonium chloride, 8 parts by weight Tributyltin fluoride, 6 parts by weight of potassium pyrrolidone carboxylate and 5 parts by weight of an antioxidant were heated to 80°C, stirred and reacted for 15 minutes, and filtered and dried with deionized water to obtain a mixture;

[0030] (3) Put the mixture obtained in step (2) into an ultrasonic reactor, add 3 parts by weight of graphene, 2 parts by weight of medical-grade nano-gyps...

Embodiment 2

[0032] A preparation method of high-performance medical special rubber, comprising the steps of:

[0033] (1) Put 60 parts by weight of medical silicone rubber material with a clean surface in an ultraviolet irradiation reactor, irradiate at a wavelength of 150nm, and irradiate for 50s to obtain surface-activated rubber;

[0034] (2) Prepare a 3wt% chitosan solution, grind the rubber obtained in step (1) and add it to the chitosan solution, heat to 70°C and stir for 15 minutes, then add 12 parts by weight of benzalkonium chloride, 10 parts by weight Tributyltin fluoride, 8 parts by weight of potassium pyrrolidone carboxylate and 6 parts by weight of an antioxidant were heated to 90°C, stirred and reacted for 12 minutes, filtered and dried with deionized water to obtain a mixture;

[0035] (3) Put the mixture obtained in step (2) into an ultrasonic reactor, add 5 parts by weight of graphene and 4 parts by weight of medical grade nano wollastonite fiber and mix for 3 minutes, an...

Embodiment 3

[0037] A preparation method of high-performance medical special rubber, comprising the steps of:

[0038] (1) Place 70 parts by weight of medical isoprene rubber material with a clean surface in an ultraviolet irradiation reactor, irradiate at a wavelength of 200nm, and irradiate for 40s to obtain surface-activated rubber;

[0039] (2) Prepare a 4wt% sodium alginate solution, crush the rubber obtained in step (1) and add it to the sodium alginate solution, heat to 80°C and stir for 10 minutes, then add 15 parts by weight of benzalkonium chloride, 12 parts by weight Tributyltin fluoride, 10 parts by weight of potassium pyrrolidone carboxylate and 8 parts by weight of an antioxidant were heated to 100°C, stirred and reacted for 10 minutes, filtered and dried with deionized water to obtain a mixture;

[0040] (3) Put the mixture obtained in step (2) into an ultrasonic reactor, add 6 parts by weight of graphene, 6 parts by weight of medical-grade nano sepiolite fiber and mix for 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com