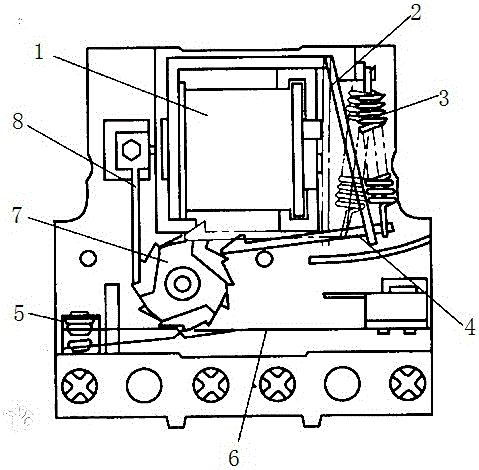

Power relay equipment for insulating building

A technology for relays and construction, applied in the direction of electromagnetic relays, relays, detailed information of electromagnetic relays, etc., can solve the problems of reduced performance, dry surface of insulating paint, pollution of the environment, etc., and achieve good mechanical properties, good insulation performance, paint film even surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] S1. Weigh 35 parts of bismaleimide resin, 22 parts of aluminum hydroxide, 33 parts of polyethylene elastomer, 11 parts of epoxy resin, 8 parts of diphenyldichlorosilane, and 15 parts of styrene 5 parts, 5 parts of cyclohexanone peroxide, 4 parts of m-p-cresol, and 3 parts of submicron quartz powder were poured into a heated electric stirring device, and stirred at a speed of 350 r / min for 9 minutes at a temperature of 90 ° C; the mixture was obtained ;

[0032] S2. Add 6 parts of vulcanizing agent, 6 parts of defoamer, 5 parts of co-solvent, 5 parts of film-forming agent and 4 parts of curing agent into the mixture in step S1, and stir at 350 r / min for 5 minutes at a temperature of 100 °C ; Obtain insulating varnish material;

[0033] S3. Use an electric polishing machine to polish the surface of the insulating shell, evenly coat the insulating varnish material prepared in step S2 on the insulating shell, dry it in a high-temperature drying oven for 60 minutes, and the...

Embodiment 2

[0035] S1. Weigh 40 parts of bismaleimide resin, 25 parts of aluminum hydroxide, 35 parts of polyethylene elastomer, 15 parts of epoxy resin, 10 parts of diphenyldichlorosilane, and 16 parts of styrene Parts, 9 parts of cyclohexanone peroxide, 15 parts of m-p-cresol, and 4 parts of submicron quartz powder were poured into a heated electric stirring device, and stirred at a speed of 350r / min for 12min at a temperature of 100°C; the mixture was obtained ;

[0036]S2. Add 6 parts of vulcanizing agent, 6 parts of defoamer, 5 parts of co-solvent, 5 parts of film-forming agent and 4 parts of curing agent into the mixture in step S1, and stir at 350r / min for 5min at a temperature of 100°C ; Obtain the insulating varnish material;

[0037] S3. Use an electric polishing machine to polish the surface of the insulating shell, evenly coat the insulating varnish material prepared in step S2 on the insulating shell, dry it in a high-temperature drying oven for 60 minutes, and then let it s...

Embodiment 3

[0039] S1. Weigh 30 parts of bismaleimide resin, 20 parts of aluminum hydroxide, 30 parts of polyethylene elastomer, 8 parts of epoxy resin, 6 parts of diphenyldichlorosilane, and 11 parts of styrene 1 part, 4 parts of cyclohexanone peroxide, 2 parts of m-p-cresol, and 1 part of submicron quartz powder were poured into a heated electric stirring device, and stirred at a speed of 300 r / min for 6 min at a temperature of 80 ° C; the mixture was obtained ;

[0040] S2. Add 2 parts of vulcanizing agent, 2 parts of defoamer, 2 parts of co-solvent, 1 part of film-forming agent and 2 parts of curing agent into the mixture in step S1, and stir at 300r / min for 2min at a temperature of 80°C ; Obtain the insulating varnish material;

[0041] S3. Use an electric polishing machine to polish the surface of the insulating casing, evenly coat the insulating varnish material prepared in step S2 on the insulating casing, dry it in a high-temperature drying oven for 40 minutes, and then let it s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com