Glue firm in adhesion and preparation technology thereof

A preparation process and bonding technology, applied in the direction of adhesives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc. , chemical corrosion resistance and poor water vapor corrosion resistance, etc., to achieve the effect of long-term viscosity change, not easy to corrupt, no unpleasant odor, and not easy to fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

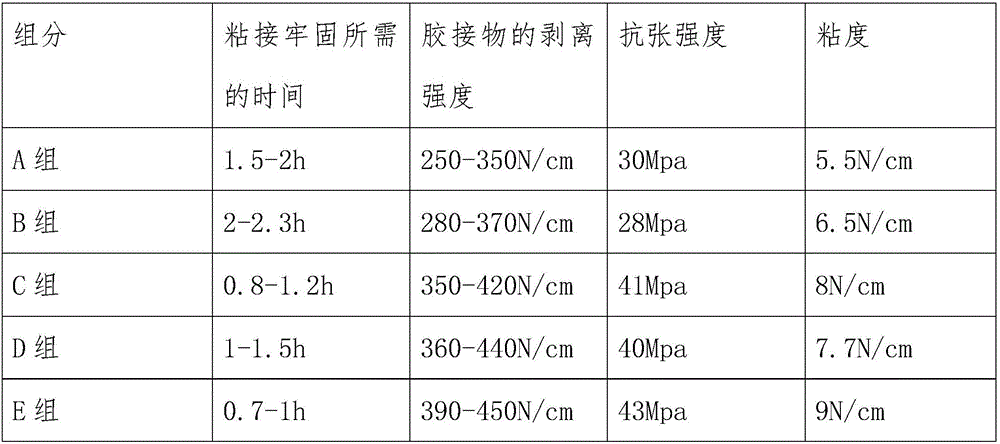

Image

Examples

Embodiment 1

[0030] A process for preparing a strong glue:

[0031] Step 1: According to each formula, it is made from the following raw materials in parts by weight: 50 parts of ethyl cyanoacrylate monomer, 3 parts of acrylamide, 3 parts of emulsifier, 5 parts of ethyl cyanoacrylate, 2.5 parts of antioxidant , 3.5 parts rosin resin, 4 parts N-phenyl-B-naphthylamine, 10 parts sodium polyacrylate, 8 parts methyl acrylate copolymer, 2 parts sulfur dioxide, 0.5 parts butyl rubber, first take ethyl cyanoacrylate monomer 50 parts, 5 parts of ethyl cyanoacrylate, 4 parts of N-phenyl-B-naphthylamine and 8 parts of methyl acrylate copolymer are added to the stirred tank for mixing. The stirred tank is airtight at room temperature without oxygen, and the stirred tank It is filled with nitrogen for protection, and then slowly heated while mixing. The ultrasonic vibration is used for mixing. The ultrasonic frequency during ultrasonic vibration is 25kHz. After 25min of mixing, it is heated to 50°C and th...

Embodiment 2

[0037] A process for preparing a strong glue:

[0038] Step 1: According to each formula, it is made from the following raw materials in parts by weight: 55 parts of ethyl cyanoacrylate monomer, 5 parts of acrylamide, 4 parts of emulsifier, 8 parts of ethyl cyanoacrylate, 1.5 parts of antioxidant , 2.5 parts of rosin resin, 3 parts of N-phenyl-B-naphthylamine, 7 parts of sodium polyacrylate, 8 parts of methyl acrylate copolymer, 3 parts of sulfur dioxide, 2.5 parts of butyl rubber, first take ethyl cyanoacrylate monomer 55 parts, 8 parts of ethyl cyanoacrylate, 3 parts of N-phenyl-B-naphthylamine and 8 parts of methyl acrylate copolymer are added to the stirred tank for mixing. The stirred tank is airtight at room temperature without oxygen, and the stirred tank It is filled with nitrogen for protection, and then is slowly heated while mixing. The ultrasonic vibration is used for mixing. The ultrasonic frequency during ultrasonic vibration is 35kHz. After 20 minutes of mixing, it...

Embodiment 3

[0044] A process for preparing a strong glue:

[0045] Step 1: According to each formula, it is made from the following raw materials in parts by weight: 53 parts of ethyl cyanoacrylate monomer, 4 parts of acrylamide, 3 parts of emulsifier, 6 parts of ethyl cyanoacrylate, 2 parts of antioxidant , 3 parts of rosin resin, 3.5 parts of N-phenyl-B-naphthylamine, 9 parts of sodium polyacrylate, 7 parts of methyl acrylate copolymer, 2.5 parts of sulfur dioxide, 1.5 parts of butyl rubber, first take ethyl cyanoacrylate monomer 53 parts, 6 parts of ethyl cyanoacrylate, 3.5 parts of N-phenyl-B-naphthylamine and 7 parts of methyl acrylate copolymer are added to the stirred tank for mixing. The stirred tank is airtight at room temperature without oxygen, and the stirred tank It is filled with nitrogen for protection, and then slowly heated while mixing. The ultrasonic vibration is used for mixing. The ultrasonic frequency during ultrasonic vibration is 30kHz. After 23min of mixing, it is he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com