Hot melt adhesive used for pipeline anticorrosion, preparation method thereof, and thermal shrinkable sleeve

A technology for hot melt adhesives and pipes, applied in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve problems such as poor low temperature performance, poor high and low temperature application range, etc., to reduce difficulty and prepare The effect is simple and easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4 to 6

[0079] The formula of embodiment 4 to 6 is as table 3, and preparation method is identical, is:

[0080] According to the formula, take the raw materials of asphalt horseshoe grease, mix with thermoplastic resin, tackifying resin, antioxidant, and filler at 140°C for about 8 minutes, and the stirring speed is 60rpm; molding is ready.

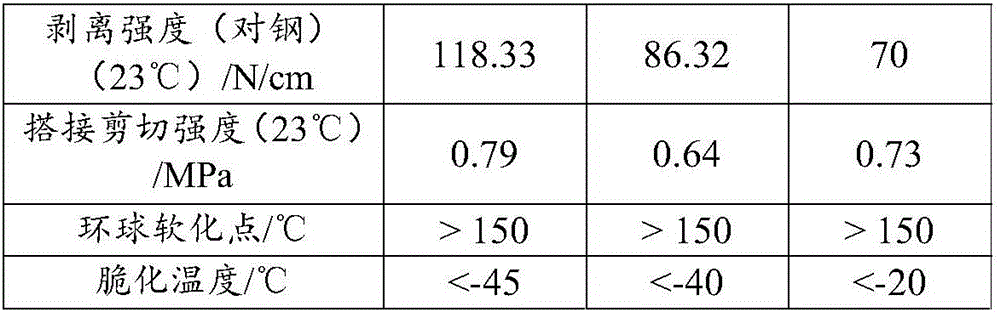

[0081] The performance results are shown in Table 4.

[0082] table 3

[0083] Parts by weight of each ingredient Example 4 Example 5 Example 6 S 60 55 55 PE 10 10 10 EVA(I) 25 20 20 Phenolic resin (I) 5 10 0 Phenolic resin (II) 0 0 10 carbon black 0 5 0 calcium carbonate 0 0 5

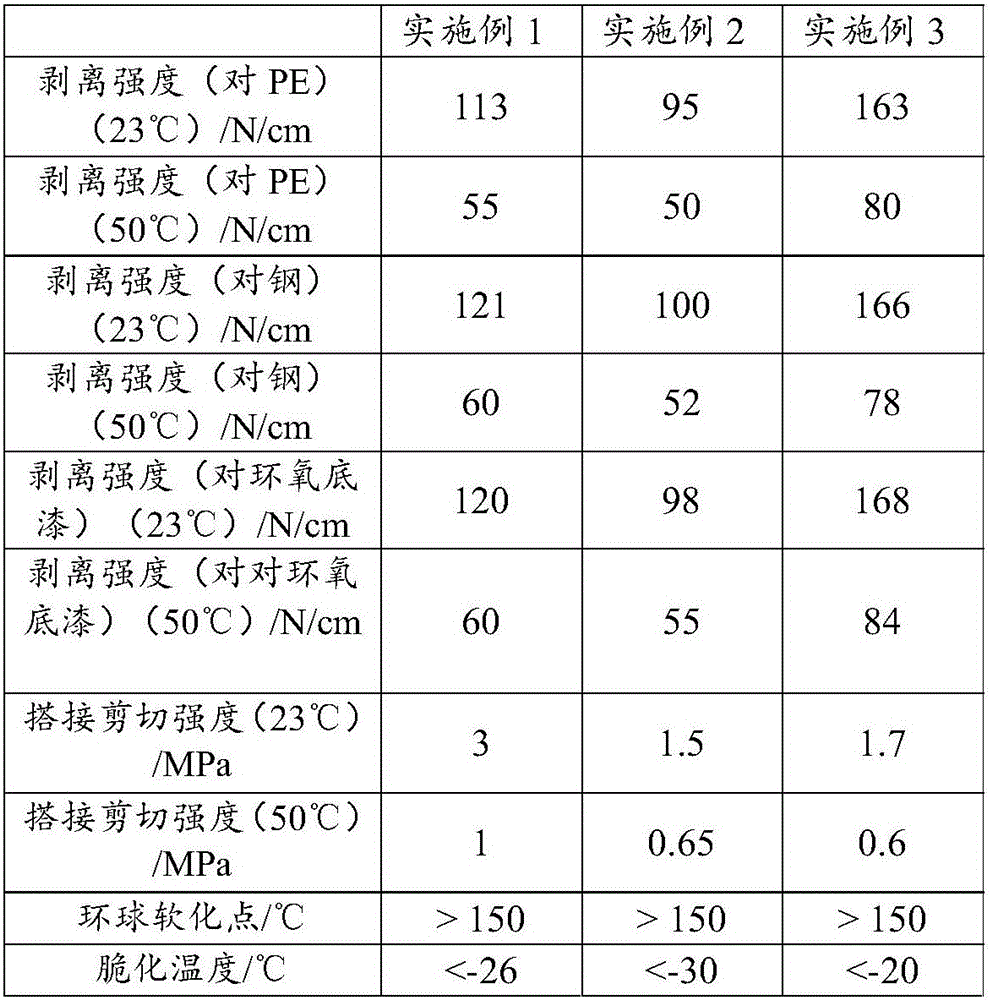

[0084] Table 4

[0085]

[0086]

Embodiment 7-9

[0088] The formula of embodiment 7 to 9 is as table 5, and preparation method is identical, is:

[0089] According to the formula, take the raw materials of asphalt horseshoe grease, mix with thermoplastic resin, tackifying resin, antioxidant, and filler at 140°C for about 8 minutes, and the stirring speed is 60rpm; molding is ready. Performance (test method is the same as embodiment 4) such as table 6.

[0090] table 5

[0091] Parts by weight of each ingredient Example 7 Example 8 Example 9 S 60 60 60 PE 5 5 5 EVA(I) 15 10 10 Phenolic resin (I) 5 5 5 carbon black 10 15 15

[0092] Table 6

[0093]

Embodiment 10

[0095] According to weight percentage, take S glue 50%, PE 10%, EVA (II) 30%, phenolic resin (I) 10%, knead at 140°C for about 8 minutes, stirring speed 60rpm; shape it.

[0096] Among them, the S glue is self-made, and the formula is: by weight percentage, 50% of recycled butyl rubber; 5% of polyisobutylene PB13005; 30% of methyl coagulated asphalt; 15% of rosin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com