Cell culture biological reactor

A bioreactor, cell culture technology, applied in the field of cell culture bioreactors, can solve the problems of cell death, restriction, low expression, etc., to achieve stable power and circulating fluid volume, ensure uniformity, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

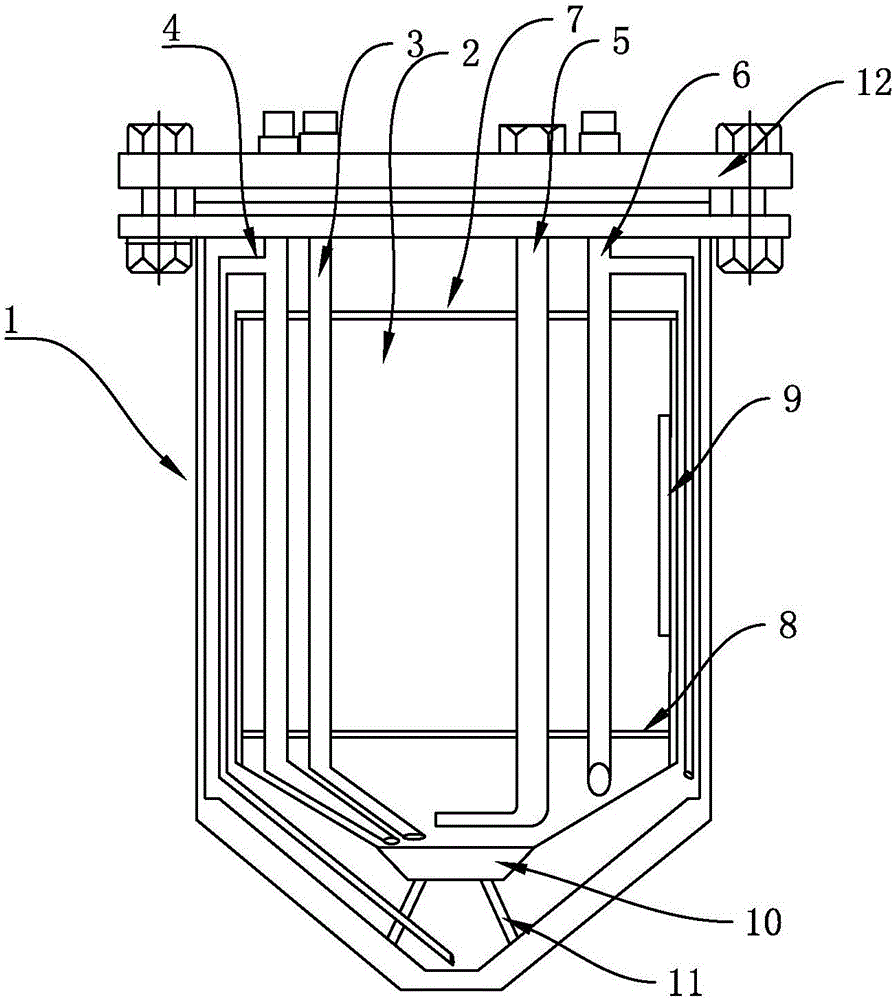

[0030] Such as figure 1 As shown, a cell culture bioreactor comprises a large tank 1, a small tank 2 and a control system, the upper end of the large tank 1 is provided with a sealing cover 12, and the sealing cover 12 is provided with a liquid inlet, Drain port, sensor port, air intake and air outlet, the two sides of the large tank 1 are provided with jackets, the jackets are connected with the control system, the sensor system 6 is arranged in the large tank, Contains sensors such as liquid level, temperature and pressure, which are all connected to the control system;

[0031] The small tank 2 is set in the large tank 1 and supported by the support frame 11 at the bottom of the large tank 1. The upper end of the small tank 2 is provided with a head 7, and the lower end is provided with a magnetic stirring system 10. , the bottom is provided with a separation plate 8 close to the bottom of the tank, and the described head 7 and separation plate 8 are stainless steel mesh p...

Embodiment 2

[0035] Such as figure 1 As shown, a cell culture bioreactor comprises a large tank 1, a small tank 2 and a control system, the upper end of the large tank 1 is provided with a sealing cover 12, and the sealing cover 12 is provided with a liquid inlet, Drain port, sensor port, air intake and air outlet, the two sides of the large tank 1 are provided with jackets, the jackets are connected with the control system, and the sensor system 6 is arranged in the large tank, Contains sensors such as liquid level, temperature and pressure, which are all connected to the control system;

[0036]The small tank 2 is set in the large tank 1 and supported by the support frame 11 at the bottom of the large tank 1. The upper end of the small tank 2 is provided with a head 7, and the lower end is provided with a magnetic stirring system 10. , the bottom is provided with a separation plate 8 close to the bottom of the tank, and the described head 7 and separation plate 8 are stainless steel mes...

Embodiment 3

[0040] Such as figure 1 As shown, a cell culture bioreactor comprises a large tank 1, a small tank 2 and a control system, the upper end of the large tank 1 is provided with a sealing cover 12, and the sealing cover 12 is provided with a liquid inlet, Drain port, sensor port, air intake and air outlet, the two sides of the large tank 1 are provided with jackets, the jackets are connected with the control system, the sensor system 6 is arranged in the large tank, Contains sensors such as liquid level, temperature and pressure, which are all connected to the control system;

[0041] The small tank 2 is set in the large tank 1 and supported by the support frame 11 at the bottom of the large tank 1. The upper end of the small tank 2 is provided with a head 7, and the lower end is provided with a magnetic stirring system 10. , the bottom is provided with a separation plate 8 close to the bottom of the tank, and the described head 7 and separation plate 8 are stainless steel mesh p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com