High-Mo Ni3Al-based monocrystal high-temperature alloy modified by rare earth and preparation method of high-Mo Ni3Al-based monocrystal high-temperature alloy

A technology of rare earth modification and high-temperature alloy, which is applied in the field of high-temperature alloys, can solve the problem of unsatisfactory oxidation resistance of alloys, and achieve the effect of improving oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention proposes that the rare earth element modified high Mo Ni 3 The Al-based single crystal superalloy is prepared by the following preparation method, which specifically includes the following steps:

[0036] The first step: prepare liquid metal cooling medium; high purity: purity ≥ 99.95%.

[0037] The liquid metal cooling medium is gallium indium alloy or metal tin. The preparation of the gallium-indium alloy: the raw materials of high-purity gallium (Ga) and high-purity indium (In), by weight percentage: gallium 10-30wt%, the rest is indium, weighed, put into a beaker and heat to 80°C ~200°C to make the reaction liquid, pour it into a liquid metal cooling tank as a cooling medium, and use vacuum pump oil to heat around the liquid metal cooling tank to keep the temperature of the cooling tank above 15 °C, so that the gallium-indium alloy remains liquid;

[0038] The preparation of the metal tin: heating the raw material high-purity tin to the melti...

Embodiment 1

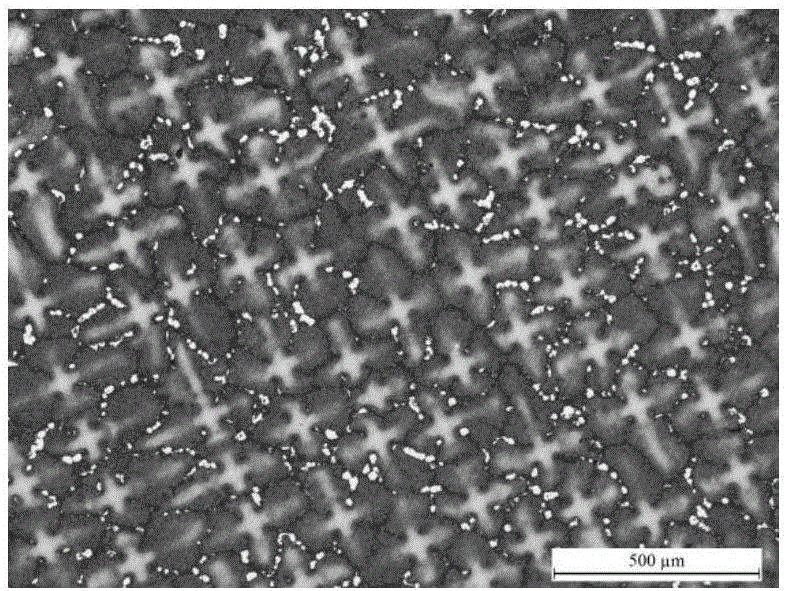

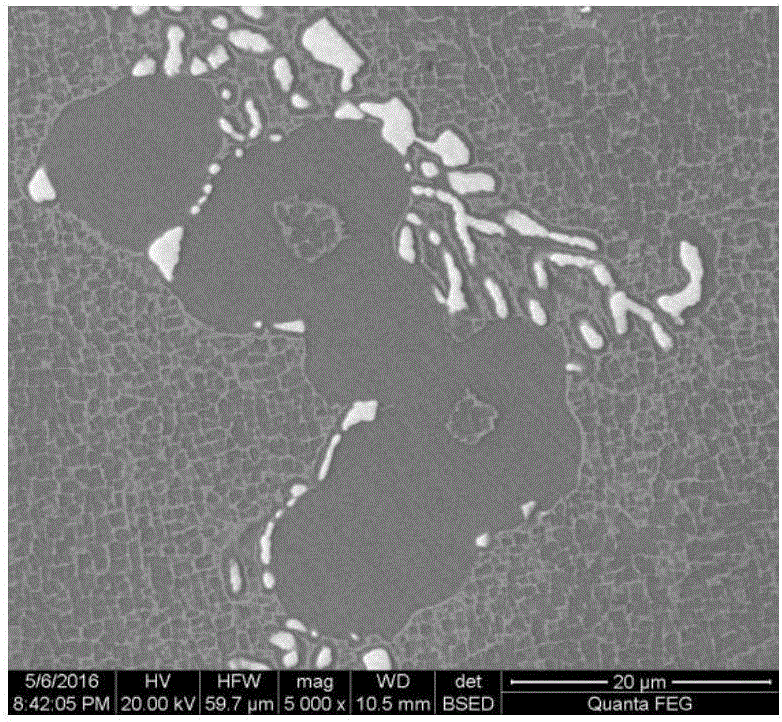

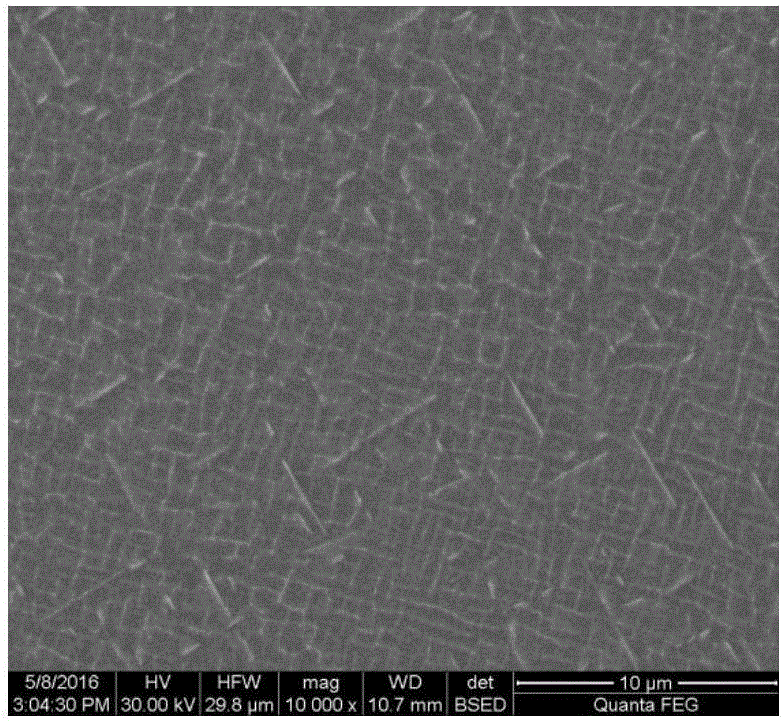

[0054] The composition of the alloy in this case is 7.6wt% Al, 9.5wt% Mo, 1.5wt% Re, 3wt% Ta, 1.5wt% Cr, 0.005wt% C, 0.05wt% Y, 0.042wt% Dy, the rest are Ni. The rare earth element modified high Mo Ni 3 The as-cast structure of Al-based single crystal superalloy includes three phase structures of γ′ phase, γ phase and white precipitate phase rich in Mo and Re. The as-cast structure is observed under light microscope and scanning electron microscope as follows figure 1 and figure 2 shown.

[0055] The present invention proposes that the rare earth modified high Mo Ni 3 The Al-based single crystal superalloy is prepared by the following preparation method, which specifically includes the following steps:

[0056] The first step: prepare liquid metal cooling medium; high purity: purity ≥ 99.95%.

[0057] The liquid metal cooling medium is gallium indium alloy or metal tin. The preparation of the gallium-indium alloy: the raw materials high-purity gallium (Ga) and high-puri...

Embodiment 2

[0077] The composition of the alloy in this case is 7wt% Al, 8wt% Mo, 1.5wt% Re, 3wt% Ta, 1.5wt% Cr, 0.001wt% C, 0.01wt% Y, 0.01wt% Dy, The rest is Ni.

[0078] The present invention proposes that the rare earth modified high Mo Ni 3 The Al-based single crystal superalloy is prepared by the following preparation method, which specifically includes the following steps:

[0079] The first step: prepare liquid metal cooling medium; high purity: purity ≥ 99.95%.

[0080] The liquid metal cooling medium is gallium indium alloy or metal tin. The preparation of the gallium-indium alloy: the raw materials high-purity gallium (Ga) and high-purity indium (In), by weight percentage: gallium 10wt%, the rest is indium, weighed, put into a beaker and heated to 80 ° C to make it After the reaction is in a liquid state, pour it into a liquid metal cooling tank as a cooling medium, and use vacuum pump oil to heat around the liquid metal cooling tank to keep the temperature of the cooling ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com