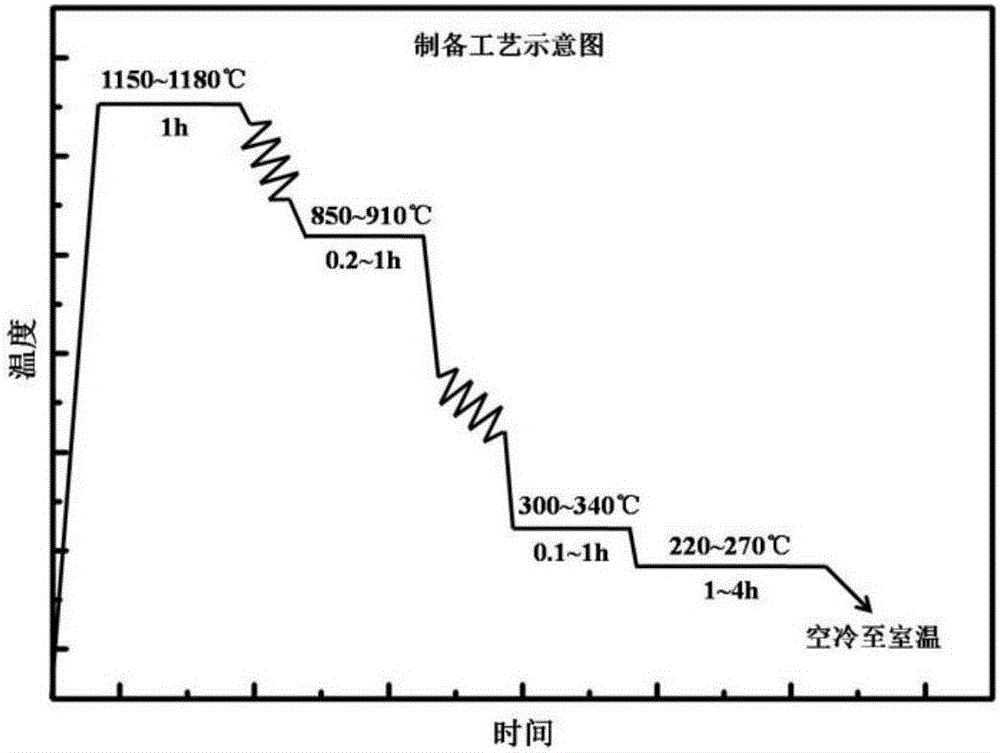

Preparation method of high-tenacity medium-and-high-carbon superfine bainite steel

A technology of bainitic steel and high toughness, which is applied in the field of preparation of high-toughness medium-high carbon ultra-fine bainitic steel. The effects of transformation time, low cost, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Heat the cast slab obtained by vacuum smelting and pouring to 1170°C for soaking, then hot-forge to a sample with a cross-sectional size of 40×40mm, then keep it at 900°C for 30 minutes, and then cool it to 570-570°C at a cooling rate of 15-20°C / s. Single-pass rolling at 595°C, the deformation is 16.6%, the temperature after rolling is 500-520°C, and then quickly put it in a salt bath furnace at 340°C for 0.5 hours, and then transfer it to a salt bath furnace at 270°C for constant temperature 2h, and finally air-cooled to room temperature. The chemical composition of the slab is shown in Table 1.

Embodiment 2

[0029] Heat the slab obtained by vacuum smelting and pouring to 1170°C for soaking, then hot forge to a sample with a cross-sectional size of 40×40mm, then keep it at 860°C for 30 minutes, and then cool it to 460~460~ at a cooling rate of 15~20°C / s. Perform single-pass rolling at 490°C, the deformation is 15.9%, and the temperature after rolling is 410-430°C, then quickly put it in a salt bath furnace at 310°C for 0.5 hours, and then transfer it to a salt bath furnace at 230°C for constant temperature 4h, and finally air-cooled to room temperature. The chemical composition of the slab is shown in Table 1.

Embodiment 3

[0031] Heat the slab obtained by vacuum smelting and pouring to 1170°C for soaking, then hot-forge to a sample with a cross-sectional size of 40×40mm, then keep it at 870°C for 30 minutes, and then cool it to 525~525~ at a cooling rate of 15~20°C / s. Single-pass rolling at 560°C, the deformation is 17.3%, the temperature after rolling is 480-500°C, and then quickly placed in a salt bath furnace at 330°C for 0.5 hours, and then transferred to a salt bath furnace at 245°C for constant temperature 2h, and finally air-cooled to room temperature. The chemical composition of the slab is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com