Preparation method of porous carbon fiber with high specific surface area

A technology of porous carbon fiber and high specific surface area, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and paper making, etc. It can solve the problems of infiltration and impossibility to improve material properties, etc., and achieve the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Add 1 part by weight of polyacrylonitrile and 0.04 part by weight of pore-forming agent to 6 parts by weight of N,N-dimethylformamide solvent, stir and disperse fully to obtain an electrospinning stock solution;

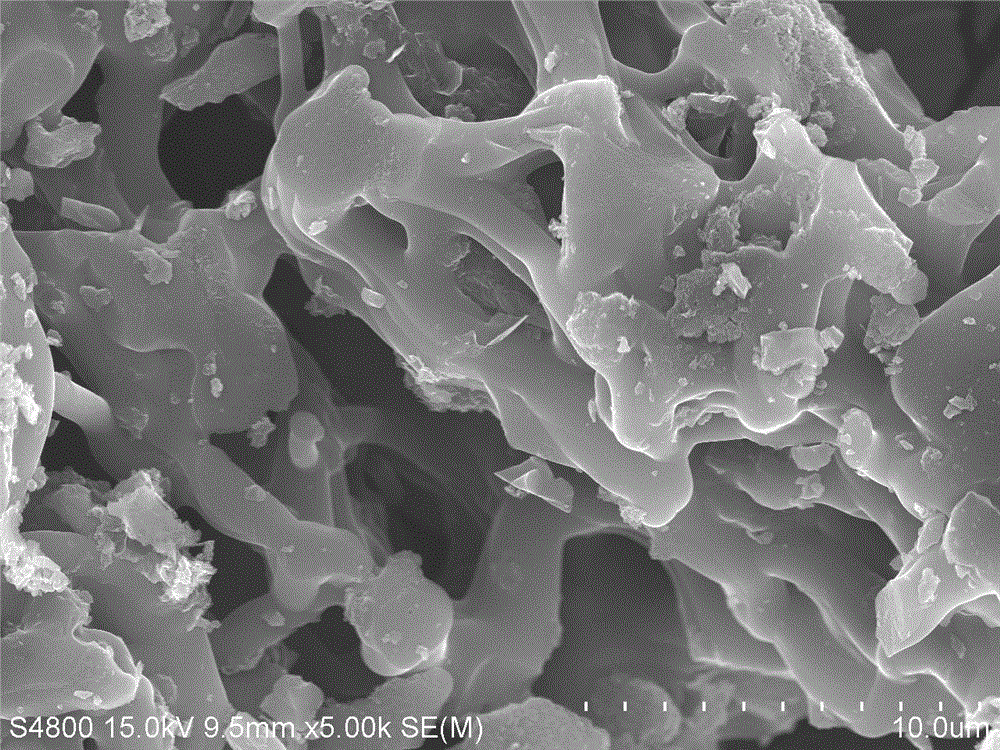

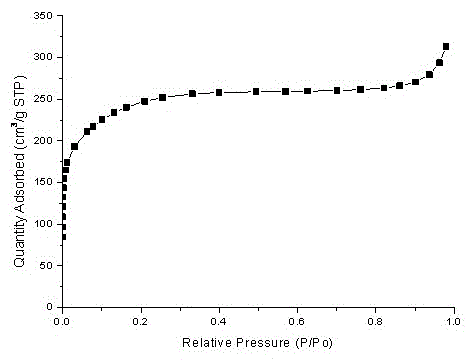

[0021] The electrospinning stock solution was spun on an electrospinning device to obtain fibers (precursor fibers). The electrospinning parameters were: spinning needle G30, spinning voltage 25kV, and spinning distance 20cm; Oxidize for 4 hours, then place the solidified viscose in a tubular carbonization furnace, raise the temperature from room temperature to 700°C at a heating rate of 5°C / min under the protection of nitrogen, carbonize at a constant temperature for 3 hours, cool down naturally and put it in the temperature Heating in 0.5M sodium hydroxide solution at 100°C for 12 hours, washing out the alkali and drying to obtain porous carbon fibers with high specific surface area. Such as figure 1 , 2 As shown, the specific surface area of ...

Embodiment 2

[0022] Example 2: Add 1 weight part of polyacrylonitrile and 0.2 weight part of pore-forming agent to 5 weight parts of N,N-dimethylformamide solvent, stir and disperse fully to obtain an electrospinning stock solution;

[0023] The electrospinning stock solution was spun on an electrospinning device to obtain fibers (precursor fibers). The electrospinning parameters were: spinning needle G30, spinning voltage 25kV, and spinning distance 20cm; Oxidize for 1 hour, then place the solidified viscose in a tubular carbonization furnace, raise the temperature from room temperature to 900°C at a heating rate of 5°C / min under the protection of nitrogen, carbonize at a constant temperature for 1 hour, cool down naturally and put it in the temperature Heat in 2M sodium hydroxide solution at 100°C for 12 hours, rinse the alkali and dry to obtain porous carbon fibers with high specific surface area.

Embodiment 3

[0024] Example 3: 1 part by weight of polyacrylonitrile and 0.1 part by weight of pore-forming agent were added to 10 parts by weight of N,N-dimethylformamide solvent, and fully stirred and dispersed to obtain an electrospinning stock solution;

[0025] The electrospinning stock solution was spun on an electrospinning device to obtain fibers (precursor fibers). The electrospinning parameters were: spinning needle G30, spinning voltage 25kV, and spinning distance 20cm; Oxidize for 2 hours, then place the solidified viscose in a tubular carbonization furnace, raise the temperature from room temperature to 800°C at a heating rate of 5°C / min under the protection of nitrogen, carbonize at a constant temperature for 2 hours, cool down naturally and put it in the temperature Heating in 1M sodium hydroxide solution at 100°C for 12 hours, washing out the alkali and drying to obtain porous carbon fibers with high specific surface area.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Micropore specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com