High-strength high-strain low-heat-conductivity-coefficient thermal-insulation/sound-insulation/fireproof integrated board and preparation method thereof

A low thermal conductivity, thermal insulation and sound insulation technology, applied in the field of building thermal insulation materials, can solve the problems of unusable thermal insulation boards, etc., and achieve the effects of improving building energy saving efficiency, simple construction, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

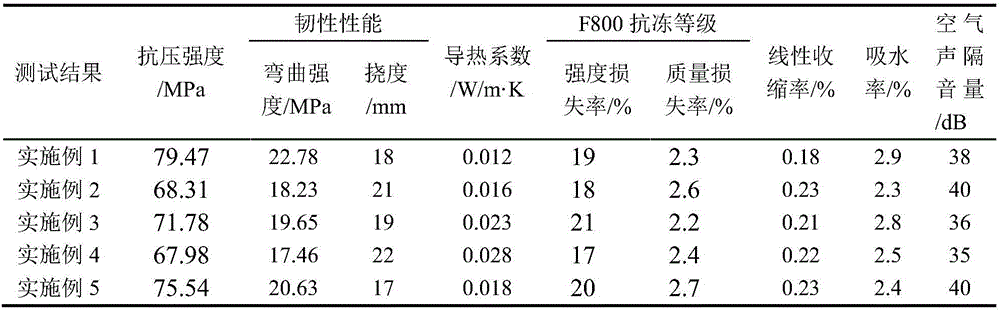

Embodiment 1

[0030] A high-strength, high-strain, low-thermal-conductivity heat-preservation, sound-insulation, and fire-proof ultra-thin integrated board is composed of a vacuum heat-insulation material and a high-strength, high-strain cement-based composite material wrapped around it.

[0031]The vacuum heat insulation material includes a core material and a high-strength gas-barrier aluminum foil. The high-strength gas-barrier aluminum foil is wrapped around the periphery of the core material and sealed with the core material by vacuum. Wherein, the core material is a nano-microporous heat insulation board, and the thickness of the core material is 4 mm. The high-strength gas-barrier aluminum foil is a commercially available aluminum foil with a thickness of 0.1 mm.

[0032] The thickness of the high-strength and high-strain cement-based composite material wrapped around the insulation core material is 6mm, and its composition is as follows: the amount of mixing water is expressed as 0....

Embodiment 2

[0034] A high-strength, high-strain, low-thermal-conductivity heat-preservation, sound-insulation, and fire-proof ultra-thin integrated board is composed of a vacuum heat-insulation material and a high-strength, high-strain cement-based composite material wrapped around it.

[0035] The vacuum heat insulation material is composed of a core material and a high-strength gas-barrier aluminum foil. The high-strength gas-barrier aluminum foil is wrapped around the periphery of the core material, and is vacuum-packed with the core material. Wherein, the core material is an airgel felt with a thickness of 2mm. The high-strength gas-barrier aluminum foil is a commercially available aluminum foil with a thickness of 0.2mm.

[0036] The thickness of the high-strength and high-strain cement-based composite material wrapped around the insulation core material is 9mm, and its composition is: the amount of mixing water is expressed as 0.24 by water-cement ratio, the volume percentage of fib...

Embodiment 3

[0038] A high-strength, high-strain, low-thermal-conductivity heat-preservation, sound-insulation, and fire-proof ultra-thin integrated board is composed of a vacuum heat-insulation material and a high-strength, high-strain cement-based composite material wrapped around it.

[0039] The vacuum heat insulation material is composed of a core material and a high-strength gas-barrier aluminum foil. The high-strength gas-barrier aluminum foil is wrapped around the periphery of the core material, and is vacuum-packed with the core material. Among them, the core material is a polyurethane insulation board with a thickness of 6mm. The high-strength gas-barrier aluminum foil is a commercially available aluminum foil with a thickness of 0.15mm.

[0040] The thickness of the high-strength and high-strain cement-based composite material wrapped around the insulation core material is 6mm, and its composition is as follows: the amount of mixing water is represented by water-cement ratio 0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com