A dimming glass based on subtractive color mixing method

A technology of dimming glass and hybrid method, which is applied in the fields of optics, nonlinear optics, chemical instruments and methods, etc., can solve the problems of unfavorable popularization and wide application of coated glass windows, reflective materials easily interfering with navigation and communication systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

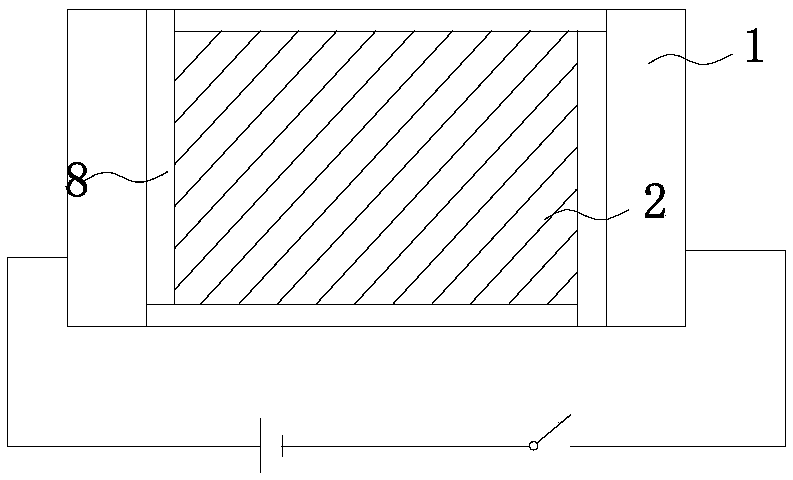

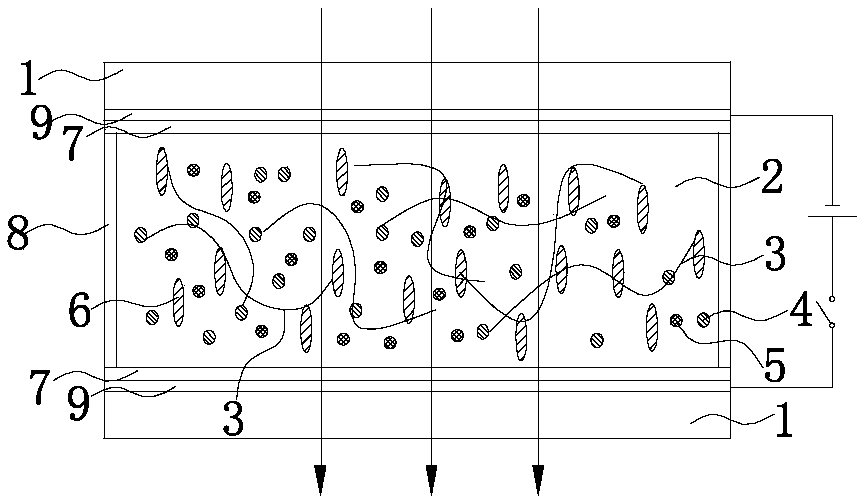

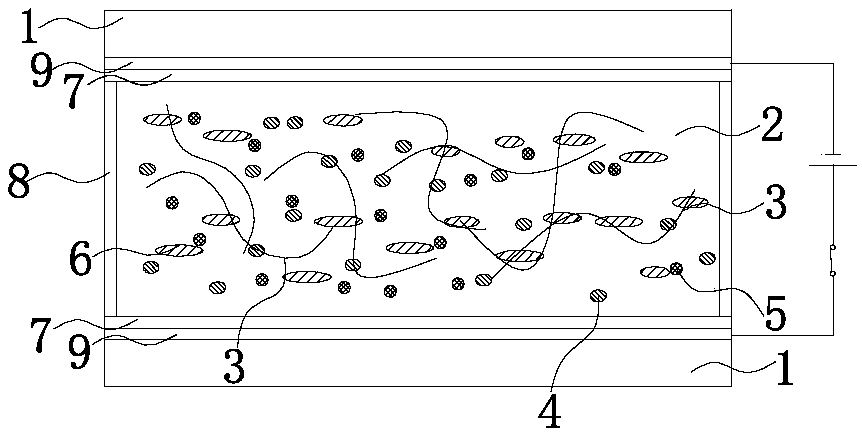

[0026] The following steps are used to prepare the switchable glass based on the subtractive color mixing method: 1) Prepare two light-transmitting substrates, the two light-transmitting substrates both include a substrate and a transparent electrode arranged on the surface of the substrate, and the two light-transmitting substrates are opposite to each other A vertical alignment layer is coated on the surface of the substrate, and an encapsulating plastic frame is used to encapsulate the space between the two light-transmitting substrates to form a liquid crystal cell, and a spacer for controlling the distance between the two light-transmitting substrates is provided in the adjustment area; 2) Preparation of mixed liquid crystals: under yellow light conditions, 91-95.8 parts by mass of negative liquid crystals, 3-5 parts by mass of photopolymerizable liquid crystal monomers, 0.5-1 parts by mass of photoinitiators and 0.5 parts by mass of -1 mass part of dichroic dye RL002, 0.1...

Embodiment 2

[0032] This example is basically the same as Example 1, except that the mixed liquid crystal is prepared by mixing negative liquid crystal, photopolymerizable liquid crystal monomer, photoinitiator and dichroic dye RL013, blue Color common dye C1 and yellow common dye Y9 were weighed into a brown reagent bottle according to the mass ratio of 94.05:3:0.5:1:0.65:0.8, and then mixed evenly to obtain a mixed liquid crystal. The liquid crystal cell prepared by dichroic dye RL013, blue common dye C1, and yellow common dye Y9 used in this example is almost colorless and transparent when no voltage is applied; when voltage is applied, it shows a lavender blurred state .

Embodiment 3

[0034] This example is basically the same as Example 1, the difference is that the mixed liquid crystal is prepared by mixing negative liquid crystal, photopolymerizable liquid crystal monomer, photoinitiator and dichroic dye RL014, red Common dye R20 and yellow common dye Y9 were weighed into a brown reagent bottle according to the mass ratio of 91:5:1:1:0.3:0.4, and then mixed evenly to obtain a mixed liquid crystal. The liquid crystal cell prepared by the dichroic dye RL014, the red common dye R20, and the yellow common dye Y9 used in this example is almost colorless and transparent when no voltage is applied; it is black and fuzzy when voltage is applied.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com