NafionTM-modified carbon quantum dot-polymer hybrid proton exchange membrane and preparing method thereof

A proton exchange membrane, carbon quantum dot technology, applied in electrochemical generators, final product manufacturing, sustainable manufacturing/processing, etc. rate reduction, good industrial production basis, and the effect of improving high temperature water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

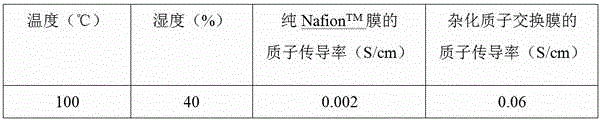

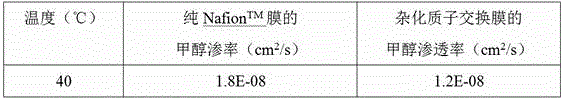

Examples

Embodiment 1

[0017] (1) Mix 2 ml of 50 mg / mL citric acid aqueous solution with 1 mL of commercially available Nafion TM The polymer solutions were mixed, sonicated for 2 h, and freeze-dried. The obtained solid was placed in a tube furnace, heated to 200°C under the protection of nitrogen, reacted for 1 h, purified by dialysis and freeze-dried to obtain Nafion TM Modified carbon quantum dots;

[0018] (2) Nafion TM Preparation of modified carbon quantum dots-polymer hybrid proton exchange membrane: 1 mg of Nafion TM Modified carbon quantum dots with 4 ml of commercially available Nafion TM The solutions were mixed and ultrasonicated for 20 min; the resulting mixture was removed by rotary evaporation to remove most of the solvent, then 4 ml of N,N-dimethylformamide was added, and rotary evaporation was continued for 20 min; after standing for 1.5 h, the above Nafion TM The casting liquid is poured into a mold with a size of 2cm×5cm, and placed in a vacuum oven, starting from 70°C for 2 h...

Embodiment 2

[0026] (1) Mix 1 mL of 50 mg / mL citric acid aqueous solution with 1 mL of commercially available Nafion TM The polymer solutions were mixed, sonicated for 2.5 h, and freeze-dried. The obtained solid was placed in a tube furnace, heated to 150°C under the protection of nitrogen, reacted for 2 h, purified by dialysis and freeze-dried to obtain Nafion TM Modified carbon quantum dots;

[0027] (2) Nafion TM Preparation of modified carbon quantum dots-polymer hybrid proton exchange membrane: 1 mg of Nafion TM Modified carbon quantum dots with 4 ml of commercially available Nafion TM The solutions were mixed and ultrasonicated for 20 min; the resulting mixture was removed by rotary evaporation to remove most of the solvent, then 4 ml of N,N-dimethylformamide was added, and rotary evaporation was continued for 20 min; after standing for 1.5 h, the above Nafion TM The casting liquid is poured into a mold with a size of 2cm×5cm, and placed in a vacuum oven, starting from 65°C for 3...

Embodiment 3

[0029] (1) Mix 3 mL of 100 mg / mL citric acid aqueous solution with 1 mL of commercially available Nafion TM The polymer solutions were mixed, sonicated for 3 h, and freeze-dried. The obtained solid was placed in a tube furnace, heated to 300°C under the protection of nitrogen, reacted for 0.5 h, purified by dialysis and freeze-dried to obtain Nafion TM Modified carbon quantum dots;

[0030] (2) Nafion TM Preparation of modified carbon quantum dots-polymer hybrid proton exchange membrane: 1 mg of Nafion TM Modified carbon quantum dots with 4 ml of commercially available Nafion TM The solutions were mixed and ultrasonicated for 20 min; the resulting mixture was removed by rotary evaporation to remove most of the solvent, then 4 ml of N,N-dimethylformamide was added, and rotary evaporation was continued for 20 min; after standing for 1.5 h, the above Nafion TM The casting liquid is poured into a mold with a size of 2cm × 5cm, and placed in a vacuum oven, starting from 70°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com