Preparation method of nanometer ZnO for lithium ion battery cathode material

A technology of lithium-ion batteries and negative electrode materials, applied in the field of electrochemical power sources, can solve the problems of poor cycle performance, rapid attenuation, and low capacity of ZnO, and achieve the effects of excellent electrochemical performance, easy reaction conditions, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A kind of preparation method of nano-ZnO for negative electrode material of lithium ion battery, it comprises the following steps:

[0017] (1) Put zinc acetate with a purity of 99.95% into a muffle furnace with a heating program, turn on the muffle furnace, rise from room temperature to a predetermined temperature of 500-800 °C, and the heating rate is 3-5° / min, Predetermined temperature of 500-800 DEG C is kept for 2-10 hours, then taken out and cooled to room temperature to obtain nanometer ZnO for negative electrode material of lithium ion battery.

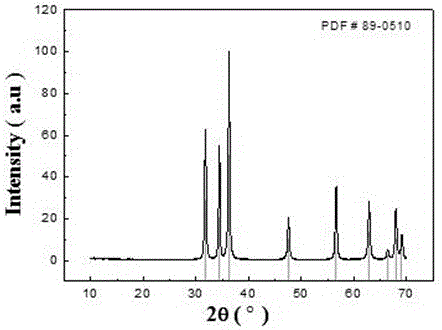

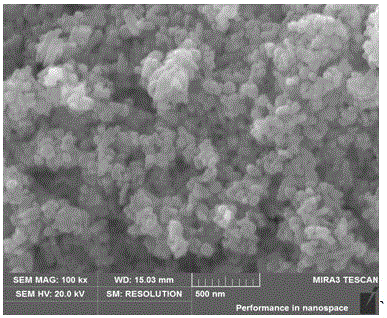

[0018] X-ray diffraction measurement shows that the prepared nano-ZnO is a wurtzite structure (attached figure 1 ), the size of nano-ZnO particles was determined to be ~40 nm by scanning electron microscopy (attached figure 2 ).

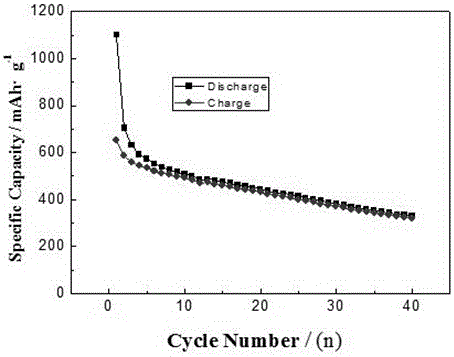

[0019] Use nanometer ZnO:SP:PVDF=8:1:1 (weight ratio) of the present invention, add appropriate amount of NMP and mix it into a slurry, coat it on copper foil and dry it in a vacuum oven fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com