Method for Separation and Purification of Flavonoid Glycosides from Lotus Seed Heart by High Speed Countercurrent Chromatography

A high-speed countercurrent chromatography, separation and purification technology, which is applied in the field of high-speed countercurrent chromatography to separate and purify flavonoid glycosides from lotus seeds, can solve the problems of large solvent consumption, large sample loss, complicated operation, etc., and achieve low overall cost and small sample loss , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

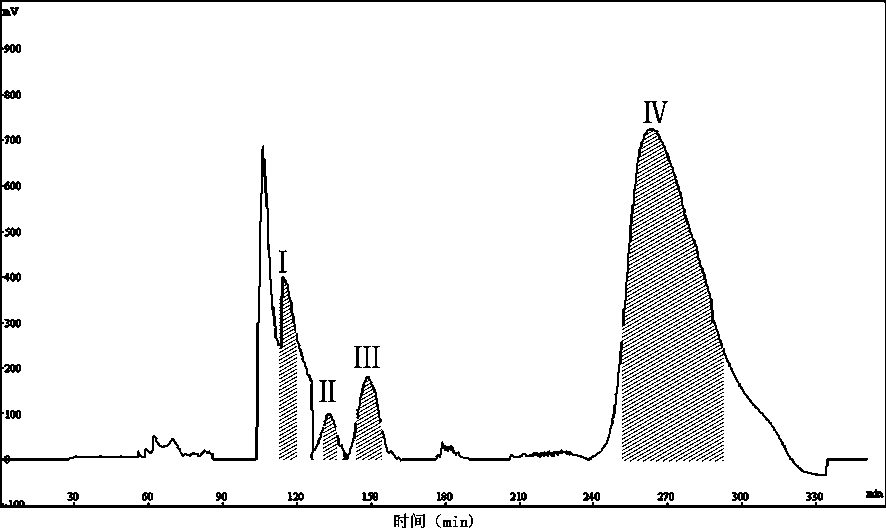

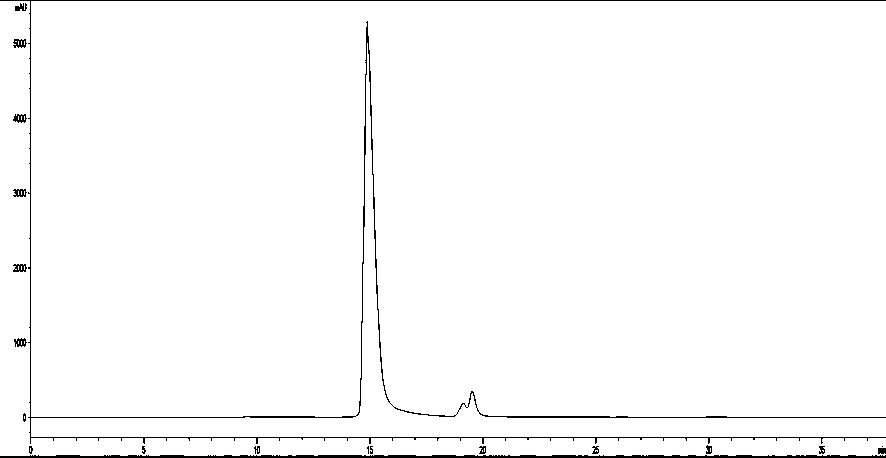

Embodiment 1

[0032] Step 1: Preparation of lotus seed heart ethanol extract

[0033] Take 1.0 kg of lotus seed heart that was naturally dried in the shade, crush it, and perform ultrasonic extraction with a concentration of 80% ethanol as a solvent, the solid-to-liquid ratio is 1:20, the extraction time is 2 hours, filter, and the filter residue is treated twice; the filtrates are combined and concentrated under reduced pressure Until there is no ethanol smell, the ethanol extract of lotus seed heart is obtained.

[0034] Step 2: Preparation of crude flavonoids from lotus seed heart

[0035] Filter the ethanol extract of lotus seed heart, select macroporous resin, polyamide, silica gel, reverse silica gel or gel as the adsorption material to absorb and filter the ethanol extract of lotus seed heart, then first use water and then use 10% to 90% ethanol Gradient elution; specifically: first elution with 10 times column volume of water, and then elution with 10%, 30%, 50%, 70%, 90% ethanol o...

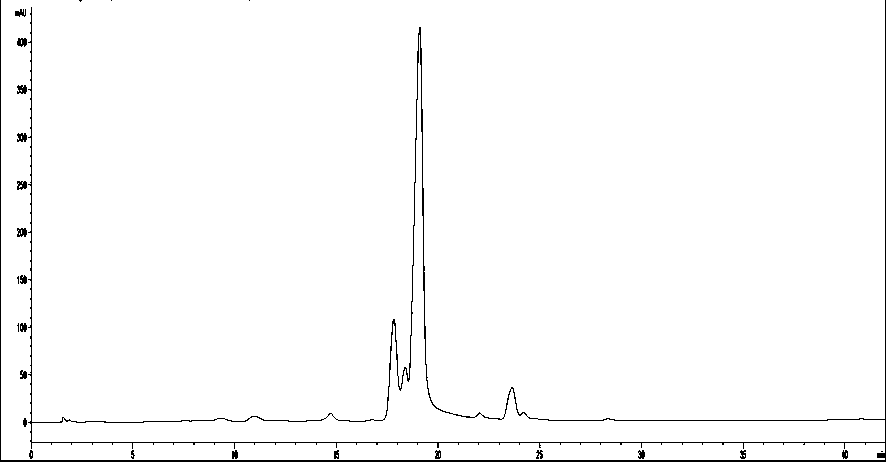

Embodiment 2

[0044] Step 1: Preparation of lotus seed heart ethanol extract

[0045] Take 1.0 kg of lotus seed heart that was naturally dried in the shade, crush it, and perform ultrasonic extraction with a concentration of 70% ethanol as a solvent, the solid-to-liquid ratio is 1:30, the extraction time is 1 hour, filter, and repeat the treatment of the filter residue once; combine the filtrates and concentrate under reduced pressure Until there is no ethanol smell, the crude ethanol extract of lotus seed heart is obtained.

[0046] Step 2: Preparation of crude flavonoids from lotus seed heart

[0047] Filter the lotus seed heart ethanol extract, select macroporous resin, polyamide, silica gel, reverse silica gel or gel as the adsorption material to absorb and filter the lotus seed heart crude extract, then use water and then use 10% to 90% ethanol Gradient elution; specifically: first elution with 10 times column volume of water, and then elution with 10%, 30%, 50%, 70%, 90% ethanol of 5...

Embodiment 3

[0053] Step 1: Preparation of lotus seed heart ethanol extract

[0054] Take 1.0 kg of lotus seed heart that was naturally dried in the shade, crush it, and perform ultrasonic extraction with a concentration of 90% ethanol as a solvent. The solid-to-liquid ratio is 1:10, and the extraction time is 3 hours. Filter and repeat the treatment of the filter residue twice; combine the filtrates and concentrate under reduced pressure Until there is no ethanol smell, the ethanol extract of lotus seed heart is obtained.

[0055] Step 2: Preparation of crude flavonoids from lotus seed heart

[0056] Filter the ethanol extract of lotus seed heart, select macroporous resin, polyamide, silica gel, reverse silica gel or gel as the adsorption material to absorb and filter the ethanol extract of lotus seed heart, then first use water and then use 10% to 90% ethanol Gradient elution; specifically: first elution with 10 times column volume of water, and then elution with 10%, 30%, 50%, 70%, 90%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com