Hydrophobic associative polymer and preparing method and application thereof

A hydrophobic association, polymer technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems affecting the water solubility of copolymers, economic pressure, construction difficulties, etc., and increase the resistance to divalent metal ions. , high viscosity, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

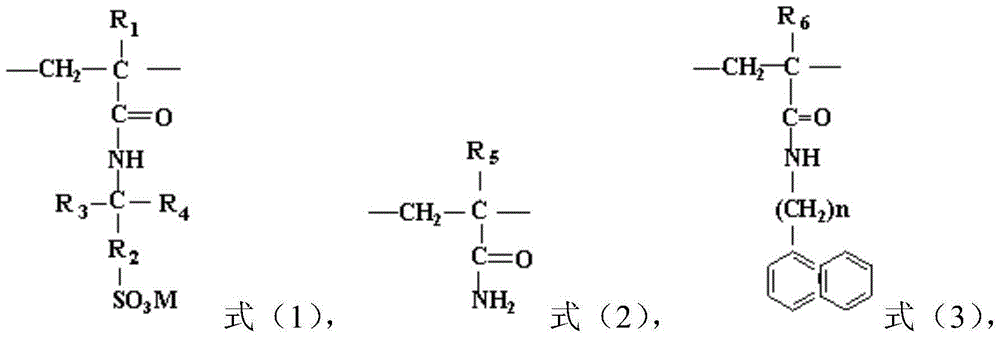

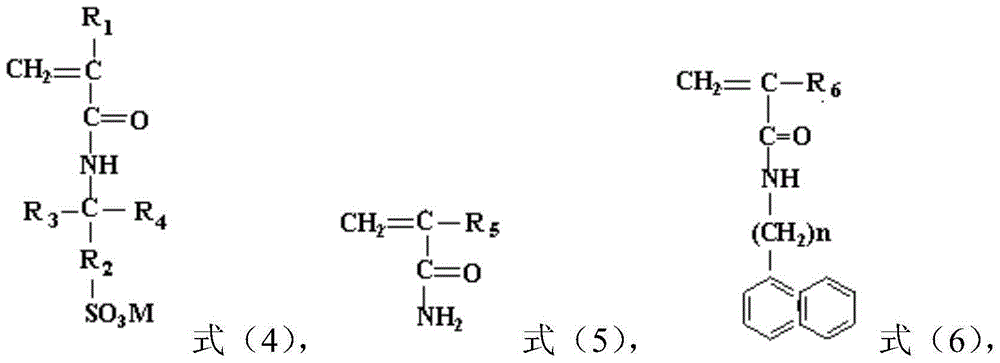

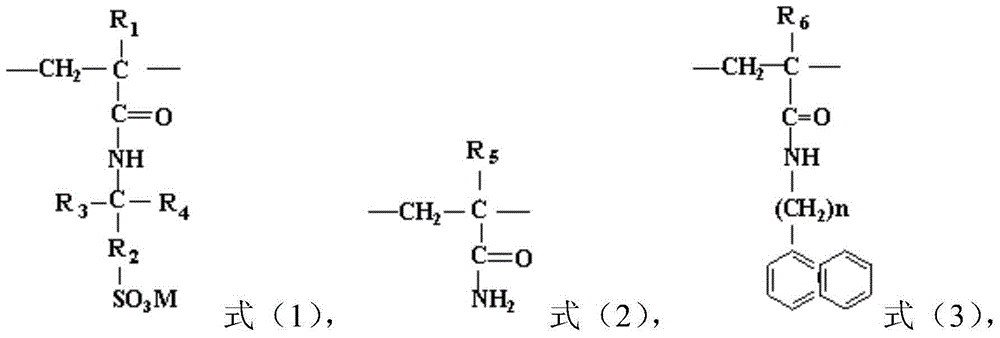

[0027] The present invention also provides a method for preparing a hydrophobic association polymer, the method comprising: in the presence of an initiator and water as a solvent, monomer D, monomer E and monomer F undergo a polymerization reaction, wherein, The monomer D is a monomer having a structure shown in formula (4), the monomer E is a monomer having a structure shown in formula (5), and the monomer F is a monomer having a structure shown in formula (6). Based on the total weight of the monomer D, the monomer E and the monomer F, the amount of the monomer D is 4-50% by weight, and the amount of the monomer E is 40-95% by weight, the amount of the monomer F is 0.05-10% by weight; the conditions of the polymerization reaction are such that the viscosity-average molecular weight of the polymer obtained after the polymerization reaction is 12 million-30 million;

[0028]

[0029] Among them, R 1 , R 5 and R 6 Each is independently H or C1-C4 alkyl, R 2 C1-C4 alkylen...

Embodiment approach

[0047] According to a preferred embodiment of the present invention, the preparation method of the hydrophobic association type polymer may specifically include the following steps:

[0048] (1) Under the condition that the pH value is 6-10, the monomer represented by the formula (4) and the monomer represented by the formula (5) are contacted with water, and nitrogen gas is blown in for 30 minutes to obtain a mixture solution;

[0049] (2) Under the protection of nitrogen, the mixture solution is contacted with the monomer represented by formula (6), a surfactant and an auxiliary agent, and mixed uniformly at 20-50° C. to obtain a micellar solution;

[0050] (3) Contacting the to-be-micellar solution with the initiator under the protection of nitrogen under the polymerization conditions, wherein the polymerization conditions are as follows: the polymerization temperature is 20-50°C; the polymerization time is 10-12h.

[0051] (4) After the polymerization reaction is completed...

Embodiment 1

[0061] This example is used to illustrate the hydrophobic association polymer and its preparation method provided by the present invention.

[0062] 1. Add 11.8g acrylamide (59% by mass ratio) and 8.0g 2-acrylamide-2-methylpropanesulfonic acid (40% by mass ratio) into a three-necked polymerization reaction bottle (ie, a polymerization bottle), Add 80.0 g of deionized water to dissolve to form an aqueous solution, then add sodium hydroxide to adjust the pH to 6.5, and blow nitrogen gas for 30 minutes;

[0063] 2. Under the protection of nitrogen, add 3.0g sodium lauryl sulfate, 0.2g hydrophobic monomer (n=1, mass ratio is 1%), 1.0g urea , placed in a 40°C water bath, stirred to disperse uniformly and form stable micelles;

[0064] 3. Under nitrogen protection, add 3.0 g of 0.1% potassium persulfate aqueous solution and 1.5 g of 0.1% sodium bisulfite aqueous solution, and maintain the polymerization reaction at 40° C. for 10 hours;

[0065] 4. After the polymerization is compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com