Preparation method of wear-resistant heat-insulation polystyrene material

A polystyrene and ethanol technology, applied in the field of preparation of polystyrene materials, can solve the problems of poor wear resistance and poor thermal insulation performance of modified polystyrene materials, and achieve improved thermal insulation performance, wear resistance, particle size and so on. The effect of uniform diameter and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

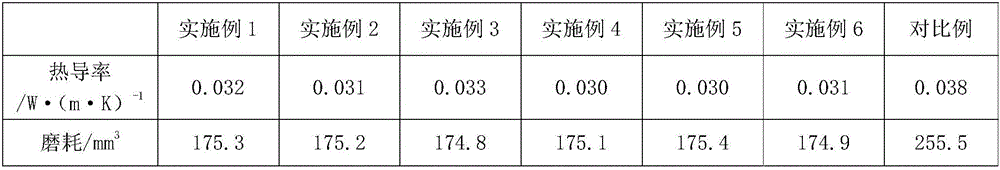

Examples

Embodiment 1

[0028] The following steps are followed to prepare the polystyrene material for wear-resistant and thermal insulation:

[0029] (1) Add sucrose to water, stir until completely dissolved to obtain a sucrose solution with a concentration of 1mol / L, place the sucrose solution in a hydrothermal reaction kettle, heat it up to 170°C and keep it warm for 8 hours, let it stand and cool to room temperature, and use ethanol The aqueous solution was washed repeatedly, and dried in an oven at 90°C to obtain carbon spheres;

[0030] (2) Add the carbon spheres obtained in step (1) into ethanol, obtain a carbon sphere solution with a mass fraction of 10% after ultrasonication for 30 min, dissolve SDBS in water to make an SDBS solution with a mass fraction of 8%, and add the SDBS solution to In the carbon sphere solution, mixed solution A was obtained after stirring at room temperature for 3 hours;

[0031] (3) Add zirconium oxychloride, hexamethylenetetramine, and urea to deionized water, a...

Embodiment 2

[0036] The following steps are followed to prepare the polystyrene material for wear-resistant and thermal insulation:

[0037] (1) Add sucrose to water, stir until completely dissolved to obtain a sucrose solution with a concentration of 1mol / L, place the sucrose solution in a hydrothermal reaction kettle, heat it up to 170°C and keep it warm for 8 hours, let it stand and cool to room temperature, and use ethanol The aqueous solution was washed repeatedly, and dried in an oven at 90°C to obtain carbon spheres;

[0038] (2) Add the carbon spheres obtained in step (1) into ethanol, obtain a carbon sphere solution with a mass fraction of 10% after ultrasonication for 30 min, dissolve SDBS in water to make an SDBS solution with a mass fraction of 8%, and add the SDBS solution to In the carbon sphere solution, mixed solution A was obtained after stirring at room temperature for 3 hours;

[0039](3) Add zirconium oxychloride, hexamethylenetetramine, and urea to deionized water, an...

Embodiment 3

[0044] The following steps are followed to prepare the polystyrene material for wear-resistant and thermal insulation:

[0045] (1) Add sucrose to water, stir until completely dissolved to obtain a sucrose solution with a concentration of 1mol / L, place the sucrose solution in a hydrothermal reaction kettle, heat it up to 170°C and keep it warm for 8 hours, let it stand and cool to room temperature, and use ethanol The aqueous solution was washed repeatedly, and dried in an oven at 90°C to obtain carbon spheres;

[0046] (2) Add the carbon spheres obtained in step (1) into ethanol, obtain a carbon sphere solution with a mass fraction of 10% after ultrasonication for 30 min, dissolve SDBS in water to make an SDBS solution with a mass fraction of 8%, and add the SDBS solution to In the carbon sphere solution, mixed solution A was obtained after stirring at room temperature for 3 hours;

[0047] (3) Add zirconium oxychloride, hexamethylenetetramine, and urea to deionized water, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com