Wood and plastic composite prepared by adopting wastes and preparation method of wood plastic composite

A wood-plastic composite material and waste technology, applied in the field of wood-plastic composite material and its preparation, can solve the problems of poor biodegradation performance, poor mechanical performance, poor heat resistance, etc. Excellent thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

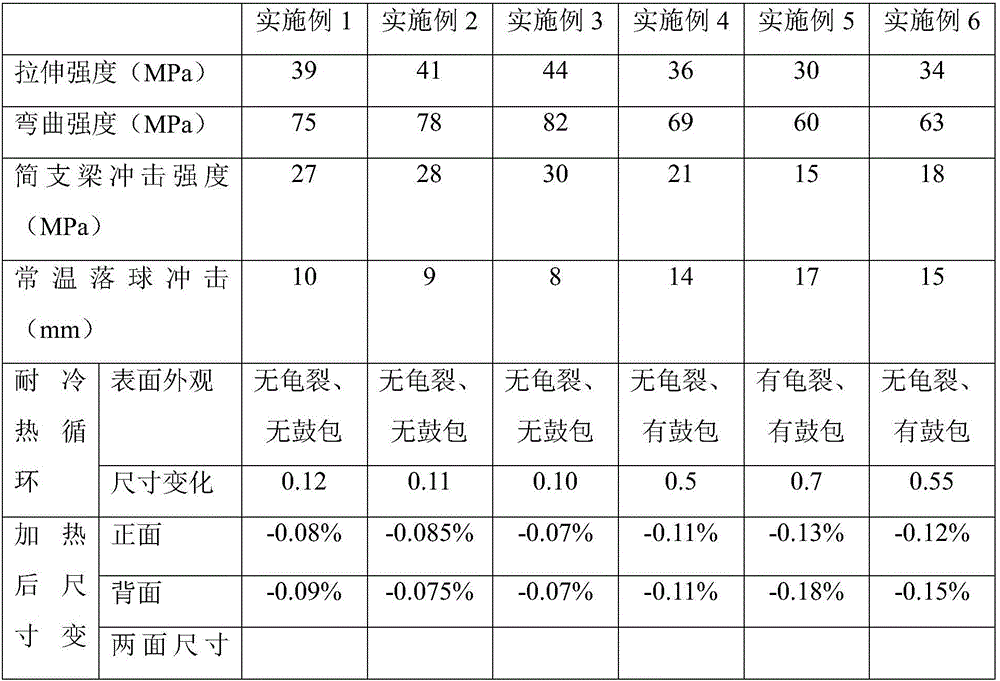

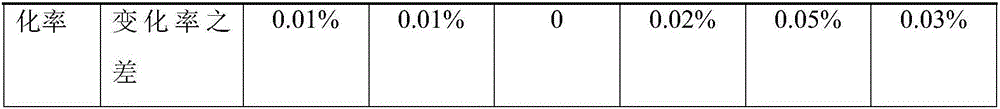

Examples

Embodiment 1

[0034] A wood-plastic composite material prepared from waste, comprising the following raw materials in parts by weight: 20 parts of modified chestnut shell powder, 10 parts of modified bamboo powder, 20 parts of modified wood powder, 20 parts of acrylate hydrophobic monomer, 15 parts of hydrophobic resin, 1 part of lubricant, 1 part of antioxidant and 1.5 parts of plasticizer.

[0035] Wherein, the modified chestnut shell powder is prepared by the following method:

[0036] (1) Soak chestnut shells in a hydrochloric acid solution with a volume fraction of 8% for 36 hours, take them out and wash them with clean water, and then dry them in a vacuum drying oven at 60°C to constant weight to obtain pretreated chestnut shells;

[0037] (2) Add the pretreated chestnut shells into the acetic acid-sodium acetate buffer solution with a pH of 4.2, the bath ratio is 1:10, then add laccase, put them in 35°C for 36 hours, take them out and wash them with hot water at 60°C, Drying at 60 D...

Embodiment 2

[0047] A wood-plastic composite material prepared from waste, comprising the following raw materials in parts by weight: 30 parts of modified chestnut shell powder, 20 parts of modified bamboo powder, 30 parts of modified wood powder, 40 parts of acrylate hydrophobic monomer, 25 parts of hydrophobic resin, 2 parts of lubricant, 2 parts of antioxidant and 3 parts of plasticizer.

[0048]Wherein, the modified chestnut shell powder is prepared by the following method:

[0049] (1) Soak chestnut shells in a hydrochloric acid solution with a volume fraction of 10% for 24 hours, take them out and clean them with clean water, and then dry them in a vacuum drying oven at 65°C to constant weight to obtain pretreated chestnut shells;

[0050] (2) Add the pretreated chestnut shells to the acetic acid-sodium acetate buffer solution with a pH of 4.2, the bath ratio is 8:55, then add laccase, put them in 40°C for 24 hours, take them out and wash them with hot water at 80°C. Drying at 60 DE...

Embodiment 3

[0060] A wood-plastic composite material prepared from waste, comprising the following raw materials in parts by weight: 28 parts of modified chestnut shell powder, 15 parts of modified bamboo powder, 26 parts of modified wood powder, 35 parts of acrylate hydrophobic monomer, 20 parts of hydrophobic resin, 1.5 parts of lubricant, 1.2 parts of antioxidant and 2 parts of plasticizer.

[0061] Wherein, the modified chestnut shell powder is prepared by the following method:

[0062] (1) Soak chestnut shells in a hydrochloric acid solution with a volume fraction of 10% for 24 hours, take them out and clean them with clean water, and then dry them in a vacuum drying oven at 65°C to constant weight to obtain pretreated chestnut shells;

[0063] (2) Add the pretreated chestnut shells to the acetic acid-sodium acetate buffer solution with a pH of 4.2, the bath ratio is 1:8, then add laccase, put them in 37°C for 30 hours, take them out and wash them with hot water at 80°C, Drying at 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com