Method for preparing phenanthrene-type (polyphenyl) phenyl polyhedral polyvinylsilicone rubber

A polyvinyl and polyphenyl technology, applied in the field of silicone rubber preparation, can solve the problems of poor compatibility, limit the use of silicone rubber adhesives, and fail to meet the heat resistance and mechanical properties of silicone rubber, so as to improve thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

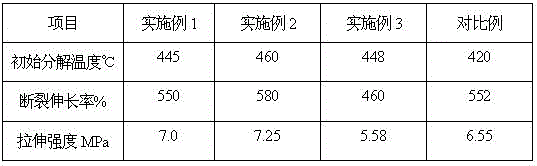

Embodiment 1

[0020] Add 20 parts of white carbon black, 5 parts of nano-tin oxide, 5 parts of nano-cerium oxide, 0.2 parts of Pt platinum catalyst, 4 parts of hydrogen-containing silicone oil, and 8 parts of phenanthrene (polyphenyl) phenyl cage polyvinyl silicone oil in order Put it into 100 parts of 107 glue, stir well and heat it in a vacuum oven to remove air bubbles. After curing, you can get high temperature resistant silicone rubber.

Embodiment 2

[0022] Add 20 parts of white carbon black, 5 parts of nano-tin oxide, 5 parts of nano-cerium oxide, 0.2 parts of Pt platinum catalyst, 4 parts of hydrogen-containing silicone oil, and 10 parts of phenanthrene (polyphenyl) phenyl cage polyvinyl silicone oil in order Put it into 100 parts of 107 glue, stir well and heat it in a vacuum oven to remove air bubbles. After curing, you can get high temperature resistant silicone rubber.

Embodiment 3

[0024] Add 20 parts of white carbon black, 5 parts of nano-tin oxide, 5 parts of nano-cerium oxide, 0.2 parts of Pt platinum catalyst, 4 parts of hydrogen-containing silicone oil, and 12 parts of phenanthrene (polyphenyl) phenyl cage polyvinyl silicone oil in order Put it into 100 parts of 107 glue, stir well and heat it in a vacuum oven to remove air bubbles. After curing, you can get high temperature resistant silicone rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com