Automatic debugging and testing system and method for attitude control engine ground test equipment

A ground test equipment and automatic debugging technology, which is applied in control/regulation systems, general control systems, and measurement electronics, can solve problems such as low efficiency, test deviation, and product performance index deviation, so as to improve efficiency, reduce a lot of work, The effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

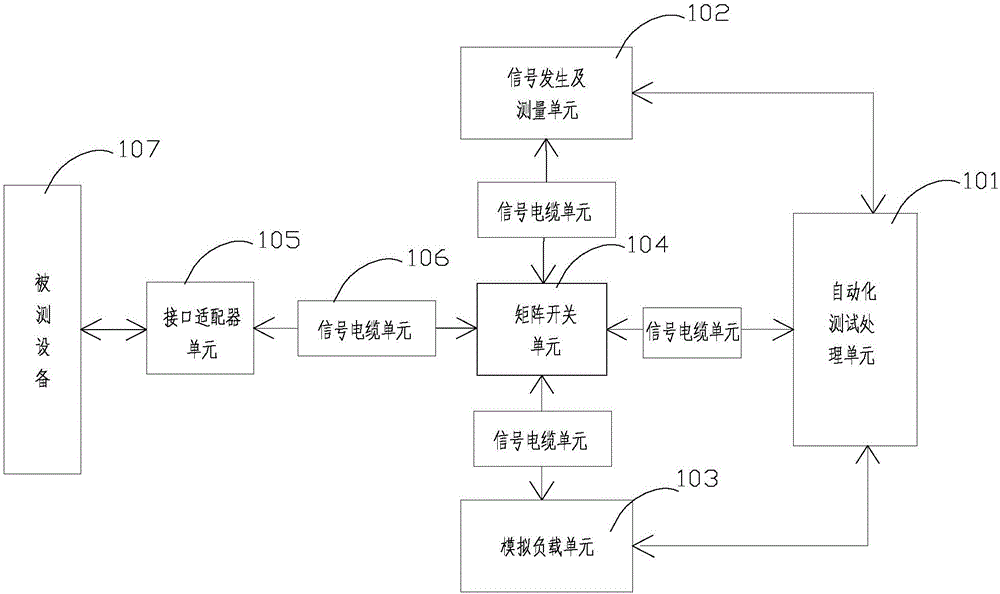

[0046] Such as figure 1 As shown, the present invention includes an automated test processing unit 101, a signal generation and measurement unit 102, an analog load unit 103, a matrix switch unit 104, an interface adapter unit 105, a signal cable unit 106, a device under test 107 and an interface adapter unit 105.

[0047] The automatic test processing unit 101 is the control core of the automatic debugging test system of the whole attitude control engine ground test equipment, and is the key to realize the automatic processing of the whole system. And the control of the measurement unit 102, the analog load unit 103, the matrix switch unit 104, and the device under test 107, to realize functions such as digital output, analog acquisition, and human-computer interaction. The specific automated test processing unit 101 analyzes the current te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com