Temperature control circuit of semiconductor laser device

A temperature control circuit and laser technology, applied in semiconductor lasers, lasers, laser parts and other directions, can solve the problems of peak current and average current error, temperature control circuit open-loop instability, slow regulation speed, etc., to improve test accuracy , Overcome nonlinear distortion, increase the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

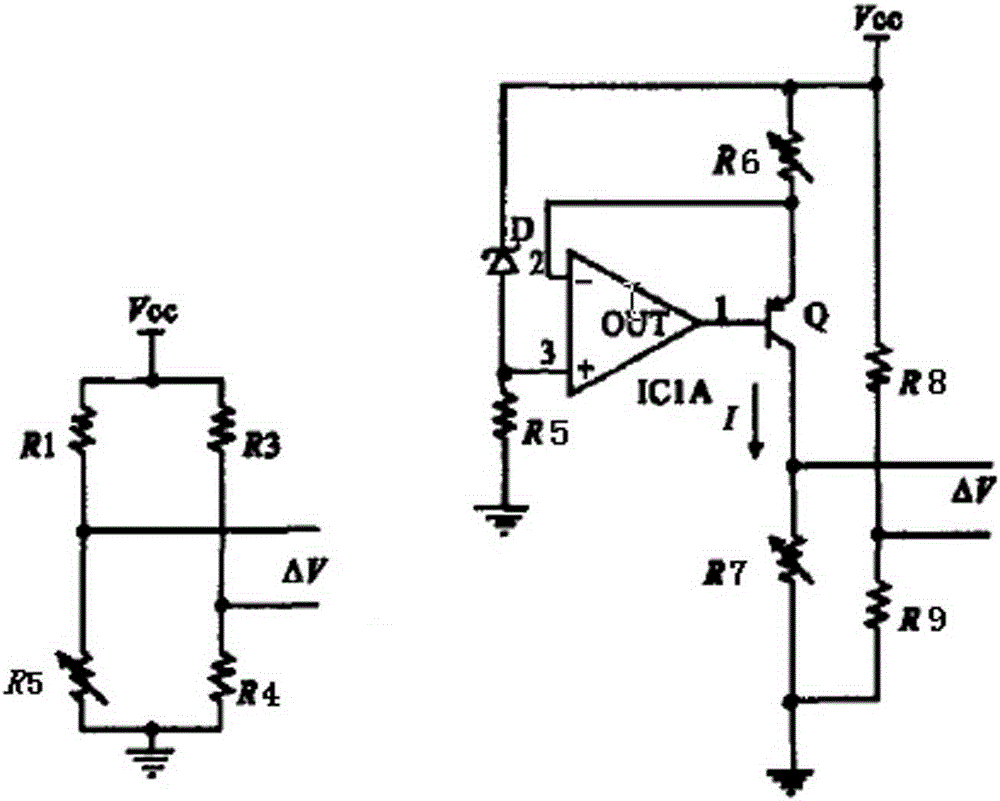

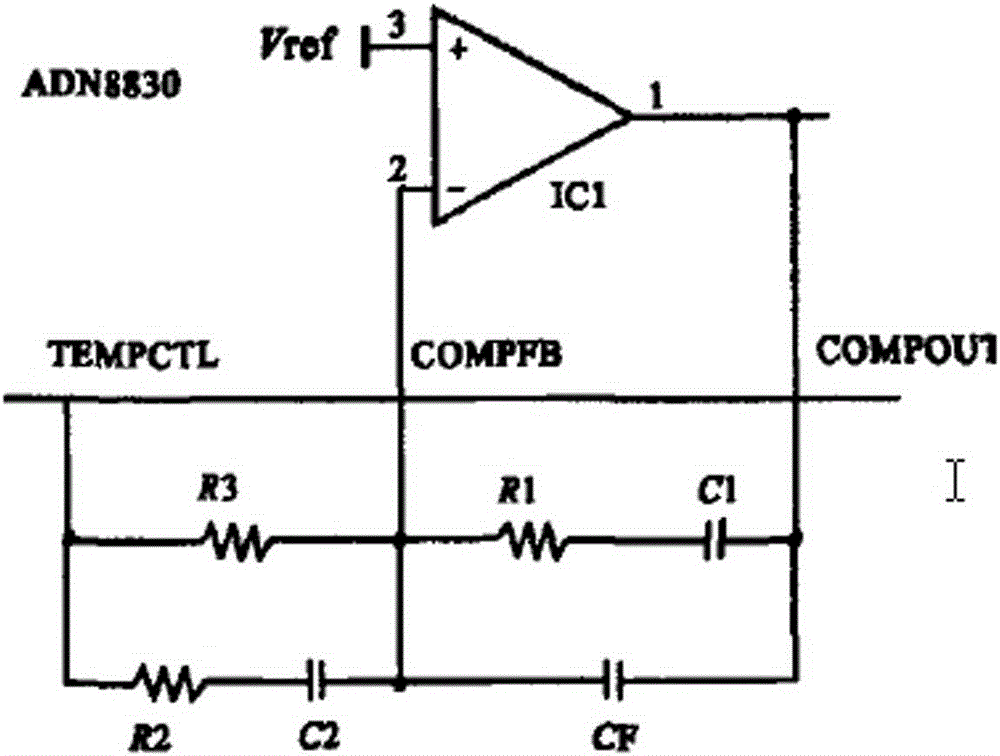

[0015] figure 1 Among them, the constant current source outputs current, and the voltage across the thermistor is the product of the output current of the current source and the resistor R7. The working temperature of LD is set by adjusting the partial pressure relationship of branches R8 and R9. When the measured temperature is equal to the set temperature, AV=0; when the LD operating temperature changes, R7 changes accordingly. It can be seen that the voltage change varies linearly with the resistance change. The temperature measuring branch circuit voltage and the temperature setting branch circuit voltage are input to ADN8830 through THERMIN pin and TEMPSET pin respectively.

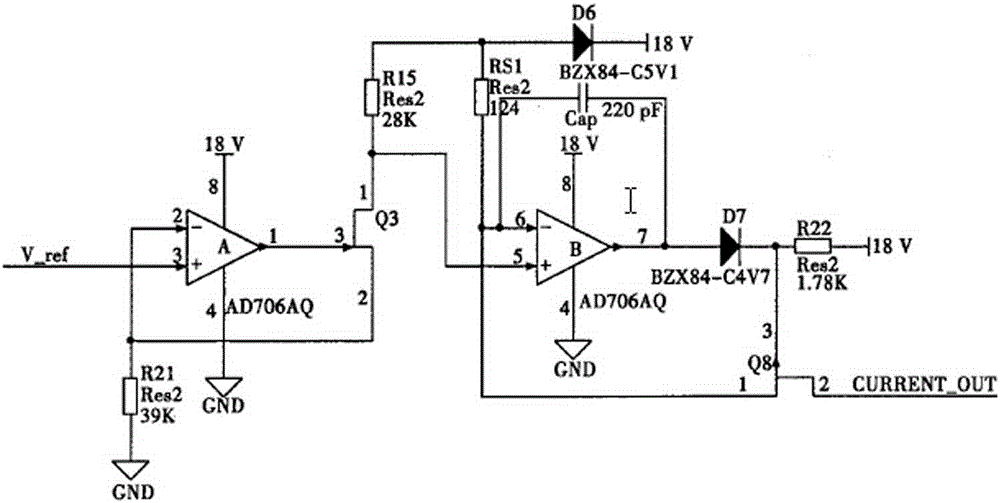

[0016] figure 2 Among them, the constant current source module adopts AD706 operational amplifier, which has the characteristics of high input impedance and low power consumption. The feedback signal is input to the positive-phase input terminal of the operational amplifier, the negative-phase in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com