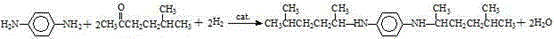

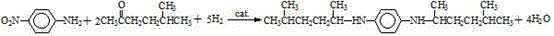

Continuous preparation method of N,N'-bis(1,4-dimethylpentyl)-p-phenylenediamine

A technology of dimethylpentyl and p-phenylenediamine, which is applied in the field of energy-saving and high-efficiency preparation technology, can solve the problems of difficulty in recycling aliphatic ketones, difficulty in recycling and utilization, and high consumption of aliphatic ketones, saving labor costs and reducing recycling and utilization. and processing costs, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

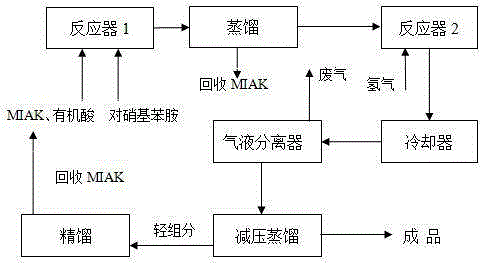

[0032] The present embodiment comprises 4 steps that carry out continuously as follows:

[0033] (1) Continuously add p-nitroaniline, 5-methyl-2-hexanone and acid into reactor 1 at a molar ratio of 1:4.5:0.008, maintain the temperature of reactor 1 at 120-125°C, and the mixed material is reacting The device 1 overflowed after staying for 1 h, and the material 1 was obtained.

[0034] (2) Material 1 enters still 1 continuously, unreacted 5-methyl-2-hexanone and water are extracted from the upper part of still 1, and the lower part of still is continuously extracted to obtain material 2. After 24 hours, take still 1 The upper sample was collected and analyzed by gas spectrometry. The content of 5-methyl-2-hexanone was 92.33%, 5-methyl-2-hexanol was not detected, and N,N'-bis(1,4-dimethyl Amyl amyl) p-phenylenediamine was not detected.

[0035] (3) The material 2 is continuously transported into the reactor 2 equipped with solid palladium-carbon catalyst, and at the same time, ...

Embodiment 2

[0038] Operating condition is the same as embodiment 1, but the used acid of step (1) is p-toluenesulfonic acid, and the used catalyzer of step (3) is the copper series catalyst that has been reduced (CuO33W%, Cr 2 o 3 12W%, Al 2 o 3 ,55W%).

[0039] Result: The sample from the upper part of the still 1 obtained in step (2) was detected and analyzed by gas chromatography. The content of 5-methyl-2-hexanone was 92.43%, and 5-methyl-2-hexanone was not detected. N, N'-bis(1,4-dimethylpentyl)-p-phenylenediamine was not detected.

[0040]Step (3) to obtain the reaction solution 3. Gas spectrum detection and analysis, the content of 5-methyl-2-hexanone is 0.64%, 5-methyl-2-hexanol is 0.13%, N,N'-bis(1,4-dimethylpentyl)p-phenyl The diamine content is 95.01%.

[0041] The finished product obtained in step (4) was tested, but p-nitroaniline was not detected, and the content of N,N'-bis(1,4-dimethylpentyl)-p-phenylenediamine was 99.14%.

Embodiment 3

[0043] The operating conditions are the same as in Example 1, but the hydrogen pressure in step (3) is 2.0MPa, and the residence time of the material in the reactor 2 is 1.5h.

[0044] Result: The sample from the upper part of the still 1 obtained in step (2) was detected and analyzed by gas chromatography. The content of 5-methyl-2-hexanone was 92.43%, and 5-methyl-2-hexanone was not detected. N, N'-bis(1,4-dimethylpentyl)-p-phenylenediamine was not detected.

[0045] Step (3) to obtain the reaction solution 3. Gas spectrum detection and analysis, the content of 5-methyl-2-hexanone is 0.44%, 5-methyl-2-hexanol is 0.05%, N,N'-bis(1,4-dimethylpentyl) p-phenyl The diamine content is 96.01%.

[0046] The finished product obtained in step (4) was tested, but p-nitroaniline was not detected, and the content of N,N'-bis(1,4-dimethylpentyl)-p-phenylenediamine was 99.70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com