A 3D printing photosensitive resin based on photomodulation of graphitic carbon nitride

A phase carbon nitride light, 3D printing technology, applied in the field of 3D printing, can solve the problems of low curing efficiency of 3D printing resin, poor aging resistance, low product precision, etc., to broaden the application market, improve aging resistance and Wear resistance, the effect of improving product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

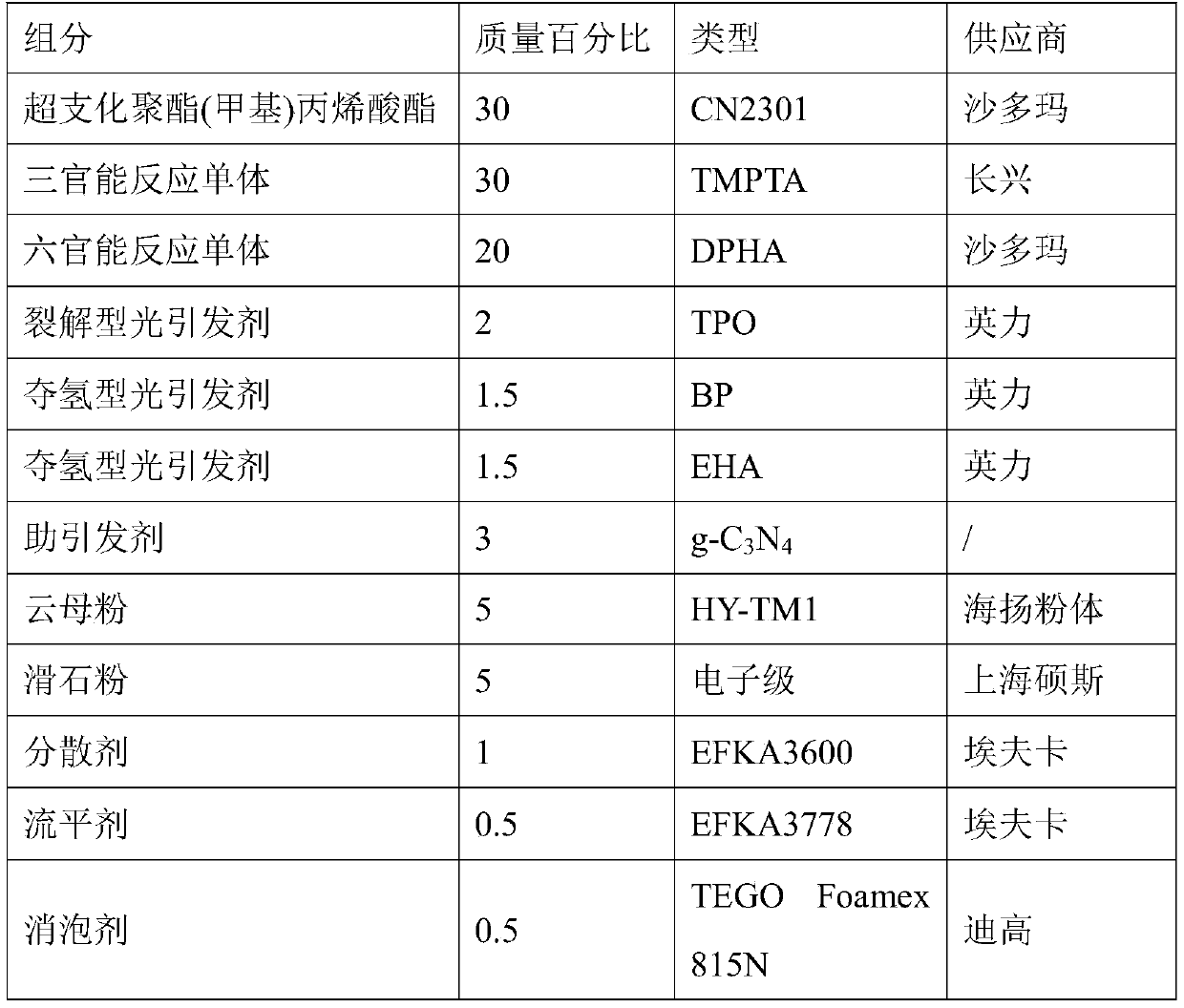

Embodiment 1

[0027] components mass percentage Types of supplier Hyperbranched polyester (meth)acrylate 35 UVR-55 Toi Polyurethane (meth)acrylate 10 611A-85 Changxing Modified epoxy (meth)acrylate 5 CN104 Sartoma monofunctional reactive monomer 22.5 IBOA Changxing Hexafunctional reactive monomer 25 EM2696 Changxing Cleavage photoinitiator 3 184 Yingli hydrogen abstraction photoinitiator 3 BP Yingli co-initiator 1 g-C 3 N 4

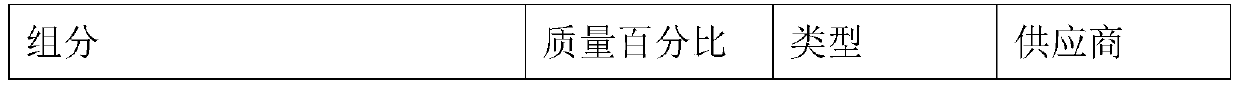

Embodiment 2

[0029]

Embodiment 3

[0031] components mass percentage Types of supplier Hyperbranched polyester (meth)acrylate 20 UV7M Xinghe Amino(meth)acrylate 10 CN978 Sartoma monofunctional reactive monomer 15 IBOA Changxing Trifunctional Reactive Monomer 25 PET3A Changxing Hexafunctional reactive monomer 20 EM2696 Changxing Cleavage photoinitiator 0.5 1173 Changxing Cleavage photoinitiator 0.5 907 Changxing co-initiator 3 g-C 3 N 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com