Device for detecting heat dissipation performance of phase change material, and method for detecting heat dissipation performance of graphene-paraffin composite material

A technology of composite materials and phase change materials, which is applied in the field of detection devices for heat dissipation performance, can solve the problems of cumbersome process, many materials, and consistent calculation results, and achieve the effect of eliminating the interference of heat dissipation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

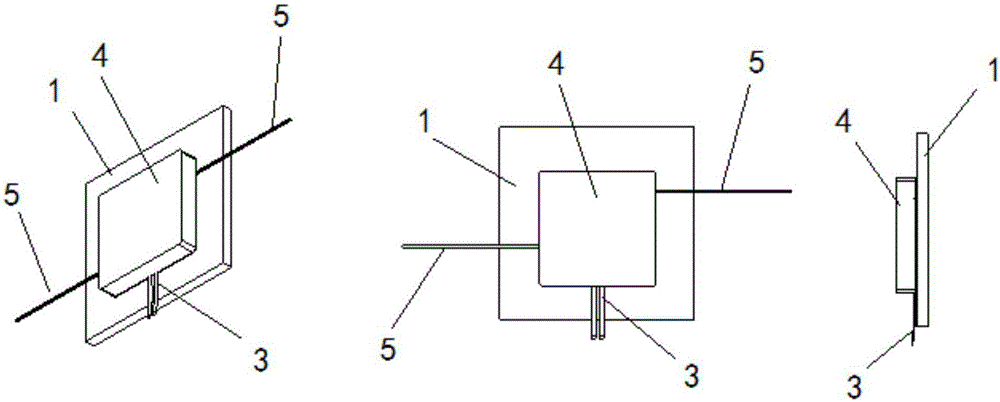

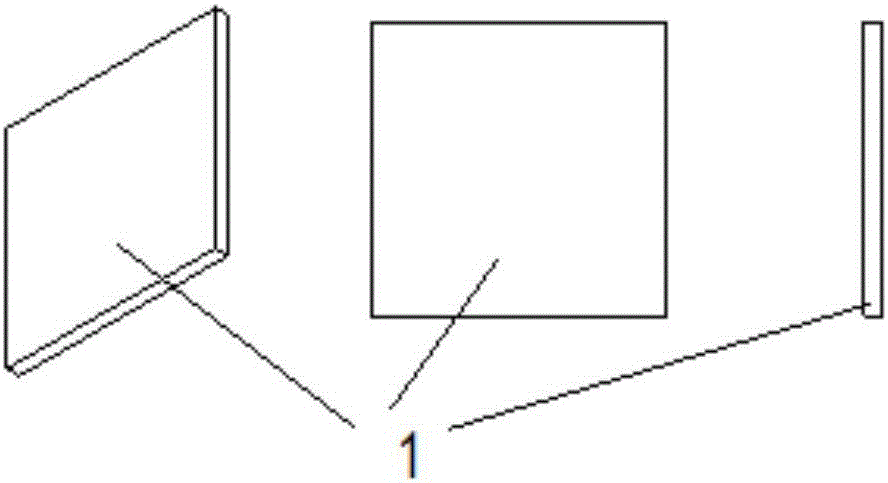

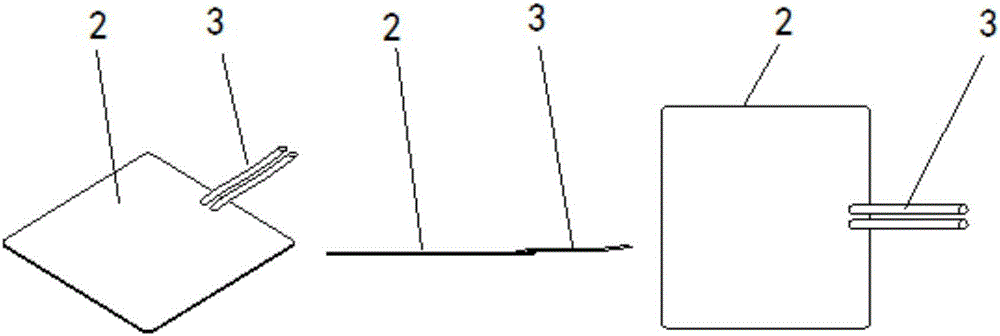

[0036] In this example, see Figure 1~4 , a detection device for the heat dissipation performance of a phase change material, including a heating body and a thermocouple 5, using a heat shield 1 as the device substrate, the heat shield 1 is made of glass fiber-based composite material, and the thermal conductivity of the heat shield 1 is The thermal conductivity of the phase change material to be tested is lower than that of the phase change material to be tested. The thin heating film 2 is used as the heating body to form a heat source area on the heat shield 1. The thin heating film 2 is made of polyimide heating film, and the thin heating film 2 is connected by a wire 3 Connect with the circuit of external power supply, thermocouple 5 is fixedly arranged between heat insulation plate 1 and sheet heating film 2, and connecting wire 3 is stretched out from the sandwich gap of heat insulation plate 1 and phase-change material cube module 4 to Outside the device, the phase chan...

Embodiment 2

[0053] This embodiment is basically the same as Embodiment 1, especially in that:

[0054] In this embodiment, 3 thermocouples 5 are used, and the positions of the two thermocouples 5 are evenly distributed; finally in step f, the temperature data of different temperature measurement points collected by the 3 thermocouples 5 can be obtained according to 3 The average temperature collected by each thermocouple 5 obtains the average temperature of the middle region of the heat source region on the heat shield 1 of the detection device of the heat dissipation performance of the graphene-paraffin wax composite material, thereby reducing test errors.

Embodiment 3

[0056] This embodiment is basically the same as the previous embodiment, and the special features are:

[0057] In this embodiment, when the sheet heating film 2 fixed on the heat insulation board 1 is partially raised or depressed to form an uneven surface shape, the graphene-paraffin wax composite cube module 4 is fixedly arranged on the heat insulation board 1 Before going up, according to the surface shape of the sheet heating film 2 fixed on the insulation board 1, earlier the surface shape of the graphene-paraffin wax composite material cube module 4 is trimmed, so that the surface shape of the graphene-paraffin wax composite material cube module 4 Adapt to the surface shape of the sheet heating film 2, and then fix the graphene-paraffin wax composite cube module 4 on the heat shield 1, and assemble it into a detection device for the heat dissipation performance of the graphene-paraffin wax composite material. In this embodiment, since the surface of the sheet heating fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com