STI diode for ESD protection

A diode and fin technology, applied in the field of STI diodes, can solve the problems of high expansion resistance, high current non-uniformity, damage, etc., and achieve the effect of improving area efficiency, good uniformity, and small on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

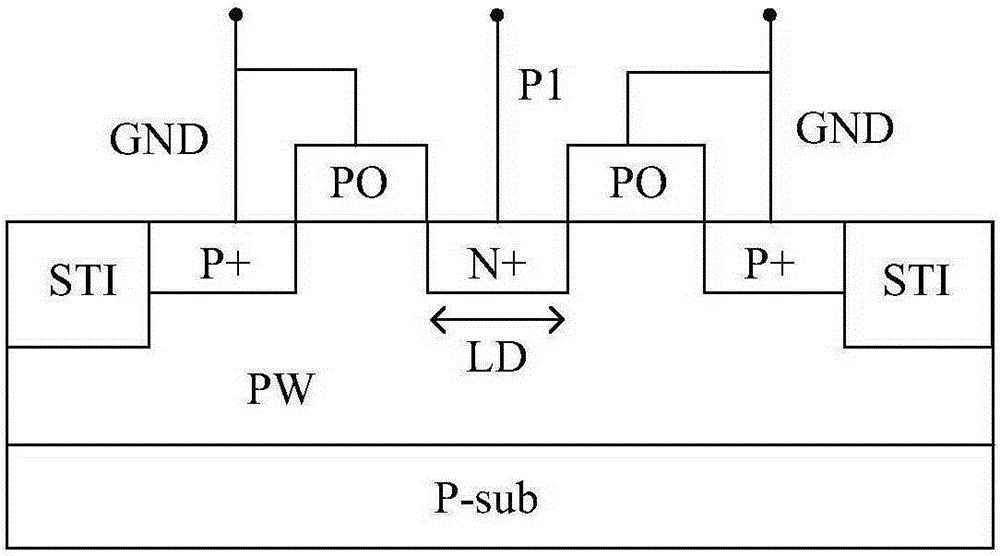

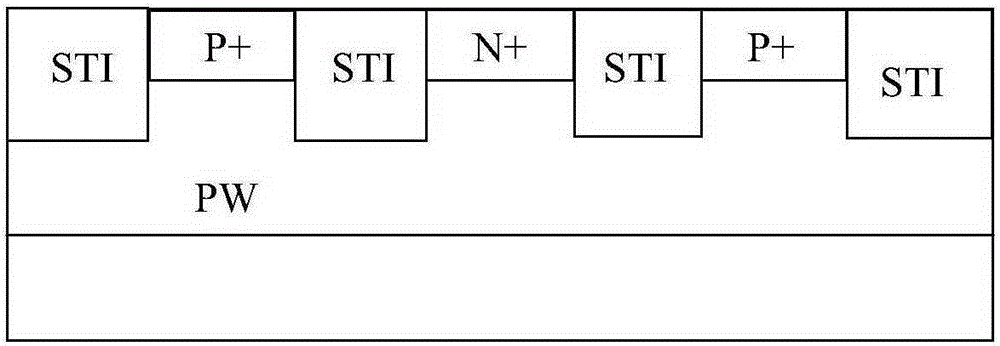

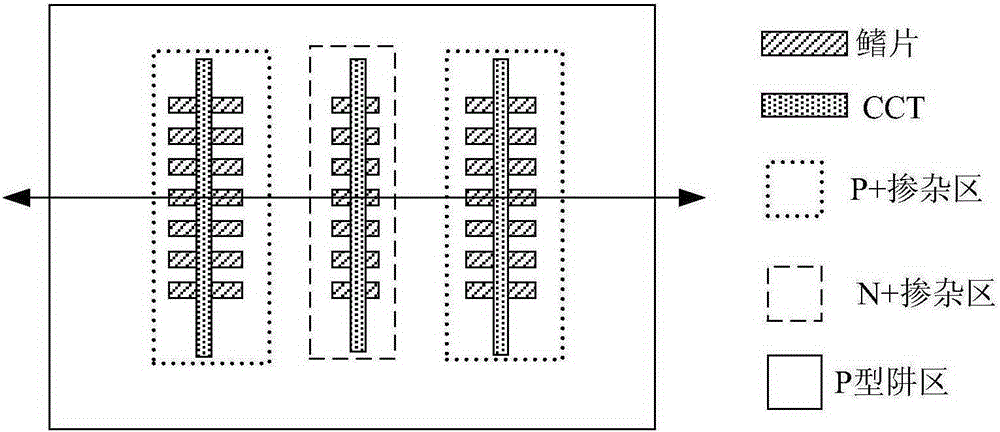

[0039] Below, refer to Figure 3A and Figure 3B An STI diode for ESD protection proposed by an embodiment of the present invention will be described. in, Figure 3A It is a plane layout diagram of a STI diode for ESD protection according to an embodiment of the present invention; Figure 3B for correspondence Figure 3A A schematic cross-sectional view of an STI diode used for ESD protection according to an embodiment of the present invention obtained by the hatching line.

[0040] Exemplarily, an STI diode for ESD protection according to an embodiment of the present invention includes:

[0041] The semiconductor substrate 100, specifically, the semiconductor substrate 100 may be at least one of the materials mentioned below: silicon, silicon-on-insulator (SOI), silicon-on-insulator (SSOI), and germanium-on-insulator Silicon (S-SiGeOI), silicon germanium on insulator (SiGeOI) and germanium on insulator (GeOI), etc.

[0042] A well region with a first conductivity type i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com