Cell-biomaterial composite support frame, and preparation method and application thereof

A technology of composite scaffolds and biomaterials, applied in liquid material additive processing, manufacturing, additive processing, etc., can solve the problems of low adhesion rate, inability to provide a three-dimensional support environment for cell growth, and large scaffold pore size, etc. Achieve the effect of being suitable for industrial production and improving the efficiency of 3D printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

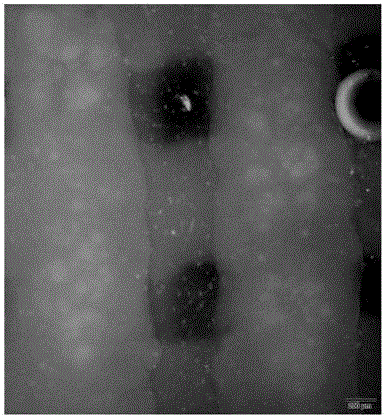

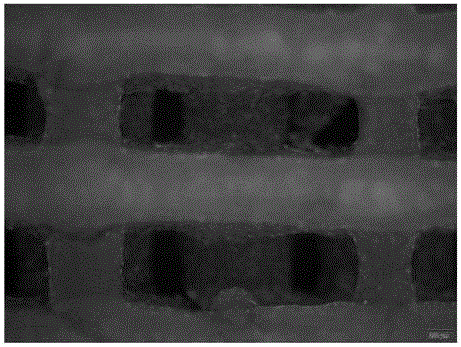

Image

Examples

Embodiment 1

[0129] A method for preparing a cell-biological material composite scaffold, comprising the following steps:

[0130] 1. Prepare scaffold matrix precursor slurry:

[0131]Inorganic nanoclay-based hydrogel is used as the precursor slurry of the scaffold matrix of the cell-biomaterial composite three-dimensional scaffold, and the preparation of the scaffold matrix precursor slurry is as follows:

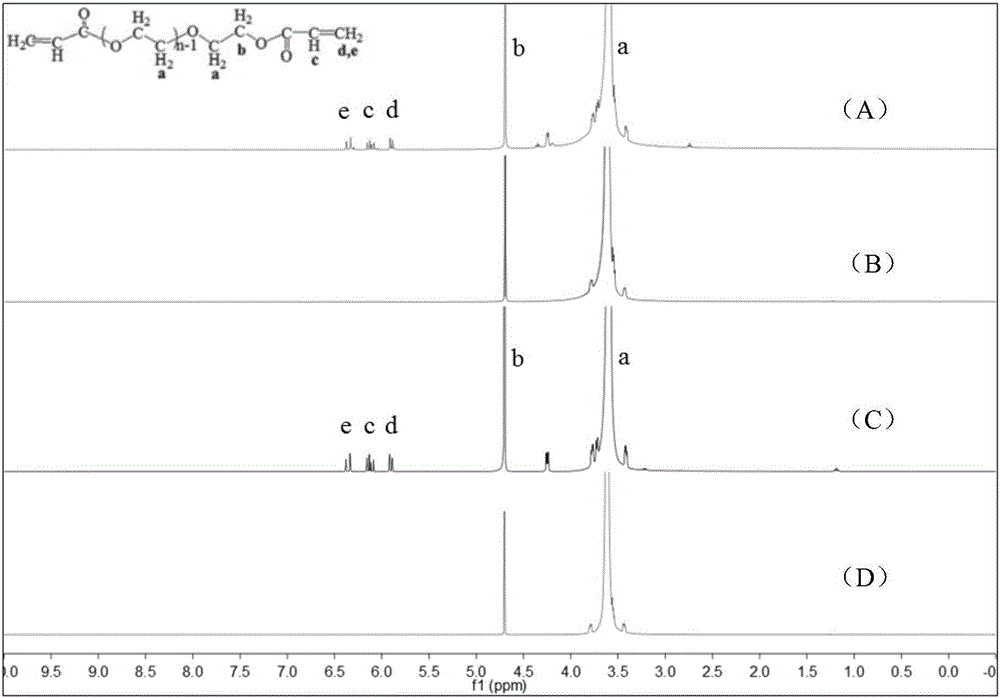

[0132] Get the polyethylene glycol macromolecular cross-linking agent modified by the above double bond, Laponite XLG laponite clay, UV photoinitiator 2-hydroxyl-2-methyl-1-phenyl-1-propanone and water to mix at room temperature , to obtain the scaffold matrix precursor slurry, the viscosity of which is 160Pa·s, wherein the above-mentioned raw materials are mixed according to the following mass percentages:

[0133] Polyethylene glycol diacrylate (molecular weight Mn=4000 of polyethylene) 20%

[0134] Laponite XLG clay: 5%

[0135] UV photoinitiator: 0.05%

[0136] Water: 74.95%. ...

Embodiment 2

[0149] A method for preparing a cell-biological material composite scaffold, comprising the following steps:

[0150] 1. Prepare scaffold matrix precursor slurry:

[0151] Inorganic nanoclay-based hydrogel is used as the precursor slurry of the scaffold matrix of the cell-biomaterial composite three-dimensional scaffold. The viscosity of the precursor slurry is 150 Pa s, including the following raw material components in mass percentage:

[0152] Crosslinking agent (methacrylic acid modified gelatin): 20%;

[0153] Laponite XLG clay: 7%;

[0154] UV photoinitiator: 0.05%;

[0155] Water: 72.95%;

[0156] Wherein, the ultraviolet photoinitiator is 1-[4-(2-hydroxyethoxy)-phenylene]-2-hydroxy-2', 2'-dimethylethanone (Irgacure2959).

[0157] 2. Prepare viscous cell suspension:

[0158] Dissolve hyaluronic acid in water to obtain a hyaluronic acid solution, resuspend human osteoblasts in the hyaluronic acid solution, and obtain a viscous cell suspension with a viscosity of 80P...

Embodiment 3

[0166] A method for preparing a cell-biological material composite scaffold, comprising the following steps:

[0167] 1. Prepare scaffold matrix precursor slurry:

[0168] Sodium alginate-based hydrogel is used as the precursor slurry of the scaffold matrix of the cell-biomaterial composite three-dimensional scaffold. The viscosity of the precursor slurry is 130 Pa s, including the following raw material components in mass percentage:

[0169] Crosslinking agent (polyvinyl alcohol modified with methacrylic acid): 20%;

[0170] Sodium alginate: 10%;

[0171] Water: 70%.

[0172] 2. Prepare viscous cell suspension:

[0173] Dissolve hyaluronic acid in water to obtain a hyaluronic acid solution, resuspend human bone marrow stem cells in the hyaluronic acid solution to obtain a viscous cell suspension with a viscosity of 200 Pa·s, in the viscous cell suspension, the mass fraction of hyaluronic acid 30%, the cell density is 2 x 10 6 individual / mL.

[0174] 3. Print composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com