Method for strengthening biological phosphorus removal of sewage and recycling phosphate resources from sewage

A sewage biological and phosphate technology, applied in chemical instruments and methods, phosphorus compounds, water/sewage treatment, etc., can solve the problems of difficult precipitation of chemical sediments and unfavorable phosphorus recovery, etc., to reduce the burden of biological treatment, convenient and efficient Effect of recycling and enhancing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

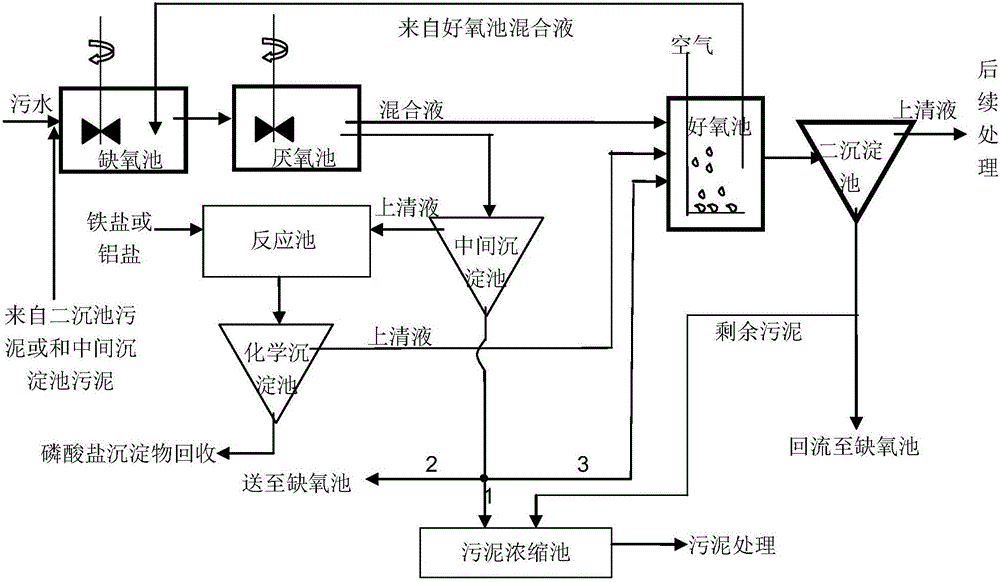

[0056] Based on inverted A 2 O system phosphorus removal recovery method (see figure 1 ):

[0057] 1) Feed domestic sewage raw water, a mixed solution containing 150% of the influent domestic sewage from the aerobic tank with a high concentration of nitrate, and the sludge returned from the secondary sedimentation tank into the anoxic tank In the process, after denitrification and denitrification, it is introduced into the anaerobic pool and stayed in the pool for 0.5 hours;

[0058] 2) After releasing phosphorus in the anaerobic tank, discharge 5% of the anaerobic tank mixed solution that has undergone sufficient anaerobic phosphorus release into the intermediate sedimentation tank; the remaining 95% of the mixed solution enters A 2 Purification treatment is carried out in the aerobic pool of the O system;

[0059] 3) The hydraulic retention time of the mixed solution in the intermediate sedimentation tank is 1h, and the mud and water are separated;

[0060] 4) 100% of th...

Embodiment 2

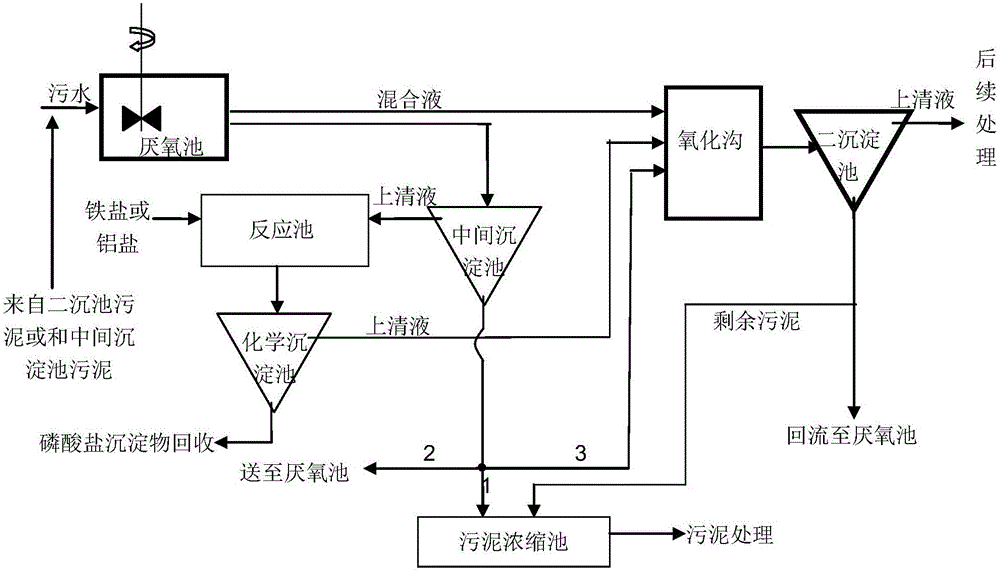

[0068] Phosphorus removal recovery method based on oxidation ditch system (see figure 2 ):

[0069] 1) Pass the domestic sewage raw water and the sludge from the intermediate sedimentation tank and the secondary sedimentation tank (equivalent to 100% of the raw water inflow of the system) into the anaerobic tank and stay in the middle pool for 1 hour;

[0070] 2) After releasing phosphorus in the anaerobic tank, discharge 30% of the anaerobic tank mixed solution that has undergone sufficient anaerobic phosphorus release into the intermediate sedimentation tank; the remaining 70% of the mixed solution enters the oxidation ditch of the oxidation ditch system for purification treatment ;

[0071] 3) The hydraulic retention time of the mixed solution in the intermediate sedimentation tank is 2h, and the mud and water are separated;

[0072] 4) 100% of the sludge settled in the intermediate sedimentation tank is discharged synchronously according to the inflow speed, and enters ...

Embodiment 3

[0080] Based on traditional A 2 O system phosphorus removal recovery method:

[0081] 1) Feed the raw domestic sewage, the high-concentration nitrate mixture from the aerobic tank equivalent to 300% of the influent domestic sewage, and the sludge returned from the secondary sedimentation tank into the anoxic tank , after denitrification and denitrification, introduce into the anaerobic tank and stay for 1 hour;

[0082] 2) After the anaerobic tank releases phosphorus, 15% of the anaerobic tank mixed solution that has undergone sufficient anaerobic phosphorus release is discharged into the intermediate sedimentation tank; the remaining 85% of the mixed solution enters the A 2 Purification treatment is carried out in the aerobic pool of the O system;

[0083] 3) The hydraulic retention time of the mixed solution in the intermediate sedimentation tank is 1.5h, and the mud and water are separated;

[0084] 4) 100% of the sludge settled in the intermediate sedimentation tank is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com