Dry type anti-seepage material used in aluminum electrolytic cell

An aluminum electrolytic cell, dry type technology, applied in the field of dry type anti-seepage materials for aluminum electrolytic cells, can solve the problems of dust generation, air pollution, biological hazards, etc., and achieve the effects of prolonging life, reducing heat dissipation, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Proportioning according to the mass ratio: 50 parts of coke gemstone, 40 parts of fly ash, 5 parts of quicklime additive, and 5 parts of quartz. The particle size ratio is: 20% of the particle size of 5-3mm, 15% of the particle size of 3-1mm, 10% of the particle size of 1-0.05mm, and 55% of the powder below 0.05mm. Lay a layer of the above-mentioned dry anti-seepage material layer on the surface of the refractory material of the electrolytic cell, when cryolite or gaseous Na + After NaF penetrates below the cathode carbon block, it reacts with the dry anti-seepage material to form a dense glassy nepheline barrier layer on its surface, thereby preventing the continuous penetration of liquid electrolyte. The reaction of the anti-seepage material under the barrier layer is kept loose, and the integrity and volume stability are good.

Embodiment 2

[0018] Proportion according to mass ratio: 60 parts of coke gemstone, 33 parts of fly ash, 5 parts of additive magnesia, and 2 parts of calcium aluminate cement. The particle size ratio is: 25% of the particle size of 5-3mm, 20% of the particle size of 3-1mm, 15% of the particle size of 1-0.05mm, and 40% of the powder below 0.05mm. Lay a layer of the above-mentioned dry anti-seepage material layer on the surface of the refractory material of the electrolytic cell, when cryolite or gaseous Na + After NaF penetrates below the cathode carbon block, it reacts with the dry anti-seepage material to form a dense glassy nepheline barrier layer on its surface, thereby preventing the continuous penetration of liquid electrolyte. The reaction of the anti-seepage material under the barrier layer is kept loose, and the integrity and volume stability are good.

Embodiment 3

[0020] Proportion according to mass ratio: 53 parts of coke gemstone, 38 parts of fly ash, 4 parts of additive magnesia, and 5 parts of quartz. Aggregate abrasive screening, 23% of the particle size is 5‐3mm, 18% of the particle size is 3‐1mm, 16% of the particle size is 1‐0.05mm, and 43% of the powder below 0.05mm. Lay a layer of the above-mentioned dry anti-seepage material layer on the surface of the refractory material of the electrolytic cell, when cryolite or gaseous Na + After NaF penetrates below the cathode carbon block, it reacts with the dry anti-seepage material to form a dense glassy nepheline barrier layer on its surface, thereby preventing the continuous penetration of liquid electrolyte. The reaction of the anti-seepage material under the barrier layer is kept loose, and the integrity and volume stability are good.

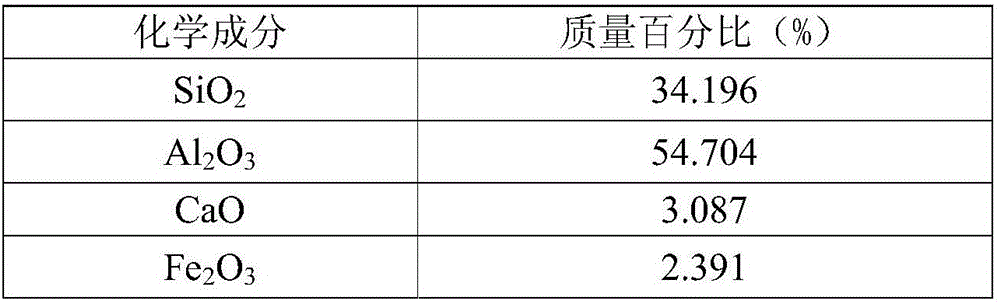

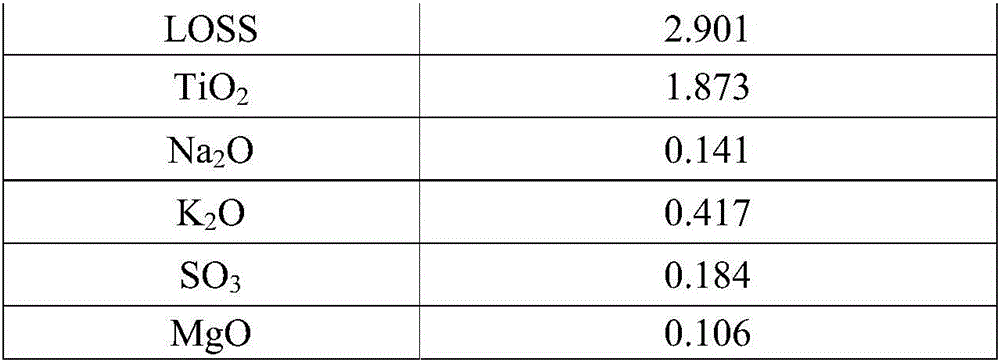

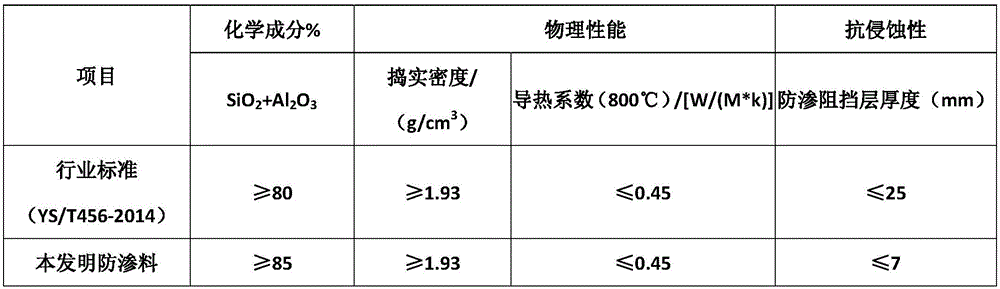

[0021] The present invention adopts a preferred formula and reasonable particle gradation, and the following table is a comparison between the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com