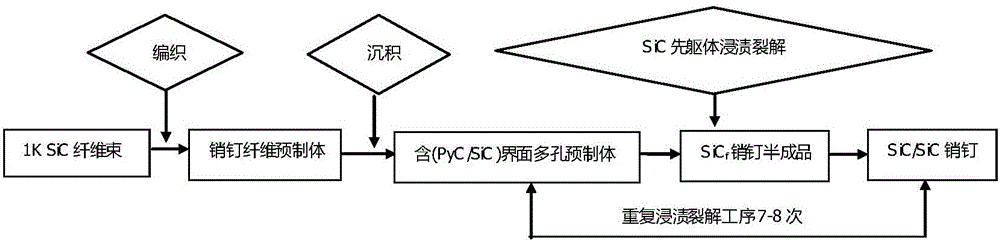

Method for manufacturing SiC/SiC composite material pin with precursor infiltration and pyrolysis method

A composite material, dipping and cracking technology, which is applied in the field of SiC/SiC composite material pins prepared by precursor dipping and cracking method, can solve the problems of high processing cost, low connection strength, processing defect composite material performance, etc., and achieves broad market promotion prospects, The effect of high connection tightening strength and low strength dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this example, 1K SiC fiber was used as reinforcement, propylene and argon were used as gas sources to prepare PyC interface layer, trichloromethylsilane, hydrogen and argon were used as precursors to prepare SiC interface layer, and liquid polycarbosilane was used as precursor body to prepare the SiC matrix, and finally obtain the SiC / SiC composite pin, including the following steps:

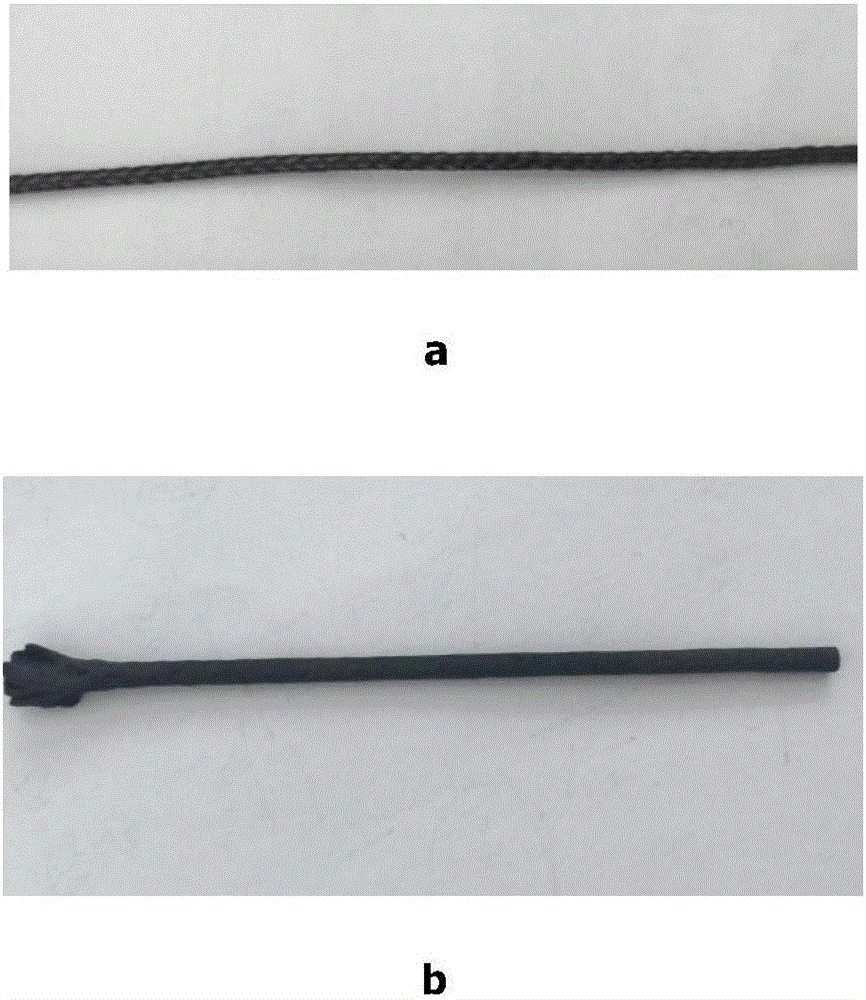

[0030] (1) The 1K SiC fiber bundle is introduced into the prefabricated body weaving machine to weave the dowel fiber prefabricated body to ensure

[0031] The content of the fiber volume fraction is 40%, and the shape of the fiber preform of the pin is cylindrical, with a diameter of 3 mm and a length of 200 mm.

[0032] (2) The obtained pin fiber prefabricated body was placed in the corresponding graphite mold for shaping, and placed in the PyC and SiC chemical vapor deposition furnaces successively to prepare the PyC / SiC composite interface layer. The precursor of PyC is propylene an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com