Preparation method of metal polyphenol vesicle material with micrometer/nanometer multilayer composite structure

A composite structure, multi-level technology, applied in the preparation of organic compounds, the preparation of aminohydroxy compounds, chemical instruments and methods, etc., to achieve rich functional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) ZIF-8 Synthesis of Colloidal Particles

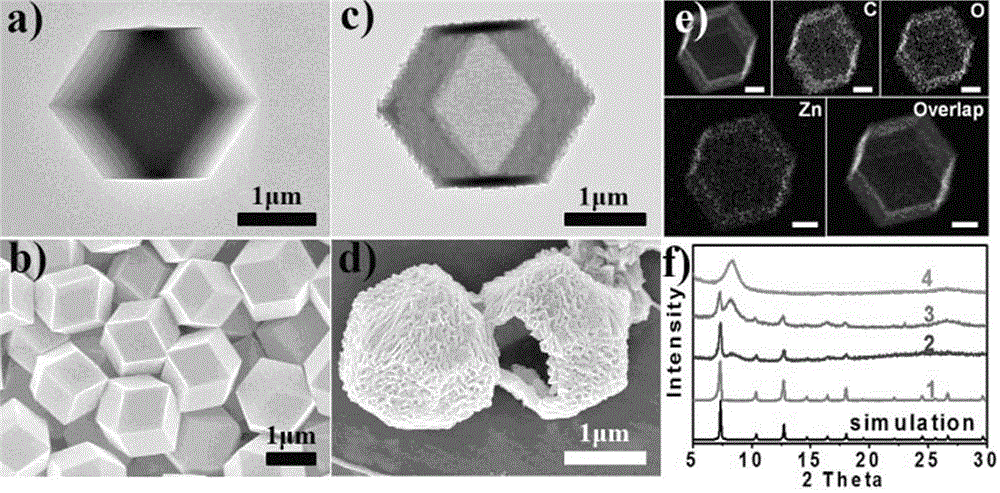

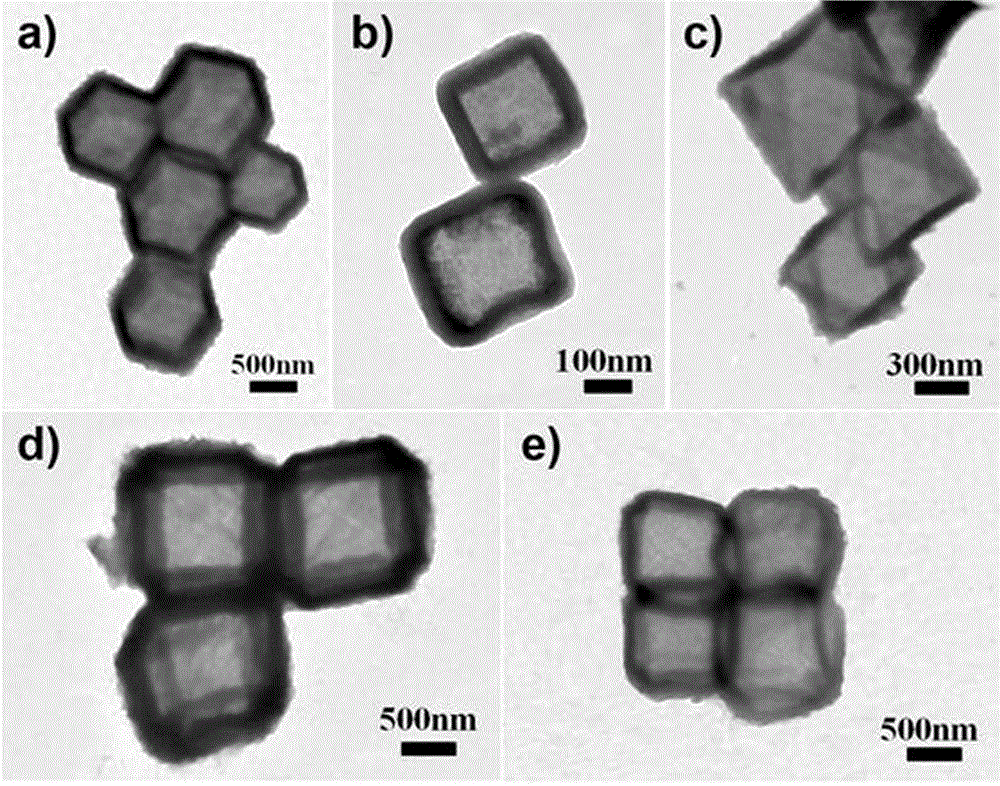

[0030] 734.4 mg Zn(NO 3 ) 2 4H 2 O was dissolved in 50 mL of anhydrous methanol to form solution a, 810.6 mg of 1-methylimidazole and 810.6 mg of 2-methylimidazole were dissolved in 50 mL of anhydrous methanol to form solution b, and solution b was poured into solution a , stirred for 20 s, and then stood for a certain period of time. The resulting precipitate was separated by filtration, washed with methanol, and left to air dry naturally. ZIF-8 The TEM and SEM pictures of the colloidal particles are as follows figure 1 a and figure 1 as shown in b.

[0031] (2) Zn-EA-capsule Synthesis

[0032] Dissolve 4 mg ellagic acid (EA) in 5 mL pH=12 (KH 2 PO 4 / NaOH) buffer solution, then add 5 mg of the prepared ZIF-8 colloidal particles to the system at 20-30 °C, stir for 4 h, centrifuge the obtained precipitate, and wash with buffer (pH=12) and water respectively Wash several times and air dry naturally. Zn-EA-caps...

Embodiment 2

[0034] (1) ZIF-67 Synthesis of Colloidal Particles

[0035] 249.0 mg Co(NO 3 ) 2 4H 2 O was dissolved in 25 mL of anhydrous methanol to form solution a, 328.0 mg of 2-methylimidazole was dissolved in 25 mL of anhydrous methanol to form solution b, and solution b was poured into solution a, stirred for 20 s, and then statically Set for 24 hours. The resulting precipitate was separated by filtration, washed with methanol, and left to air dry naturally.

[0036] (2) Co-EA-capsule Synthesis

[0037] With embodiment 1, ZIF-8 colloidal particle is changed into ZIF-67 Colloidal particles are sufficient.

Embodiment 3

[0039] (1) PB (Prussian Blue) Synthesis of Colloidal Particles

[0040] Combine 3.8 g PVP(K30) and 0.11 g K 4 Fe(CN) 6 4H 2 O was dissolved in 50 mL of 0.1 mol / L HCl solution, stirred to dissolve, and then allowed to stand at 80 °C for 24 h. The obtained blue precipitate was separated by filtration, washed with methanol, and then placed in air to dry naturally.

[0041] (2) Fe-EA-capsule Synthesis

[0042] With embodiment 1, ZIF-8 colloidal particle is changed into PB Colloidal particles are sufficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com