Alginate/hydroxyapatite super-long nanowire composite hydrogel

A technology of hydroxyapatite and composite hydrogel, which is applied in the direction of prosthesis, inorganic non-active ingredients, aerosol delivery, etc. It can solve the problems of difficult to obtain mechanical properties, complex shape, uncontrollable gelation rate, etc. problems, to achieve good application prospects, uniform structure, good biocompatibility and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

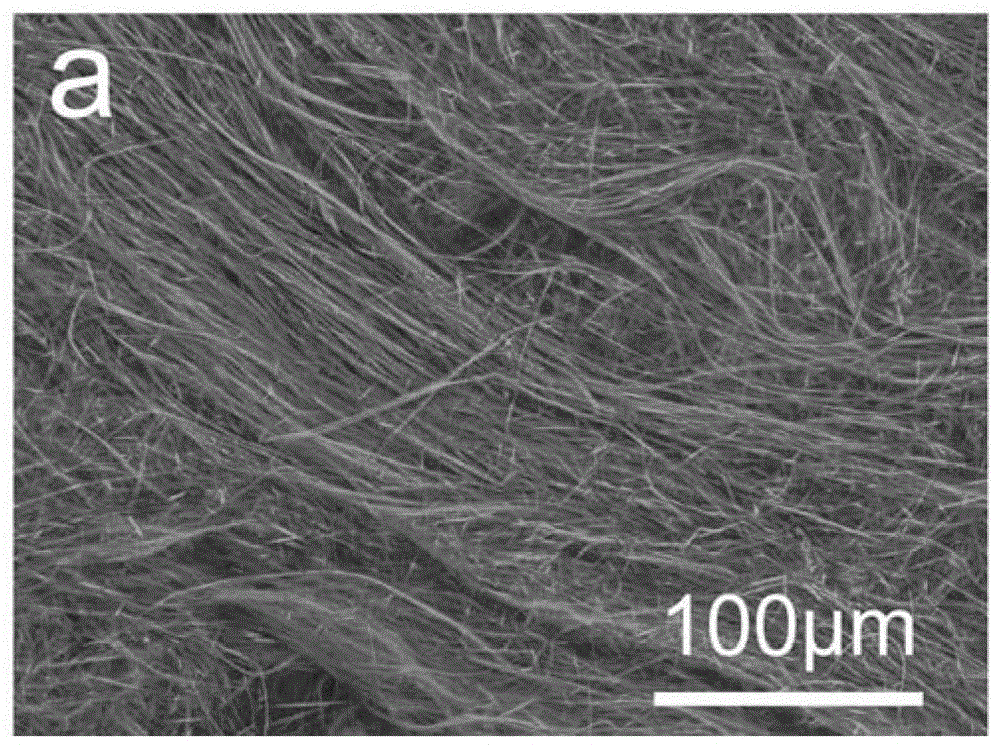

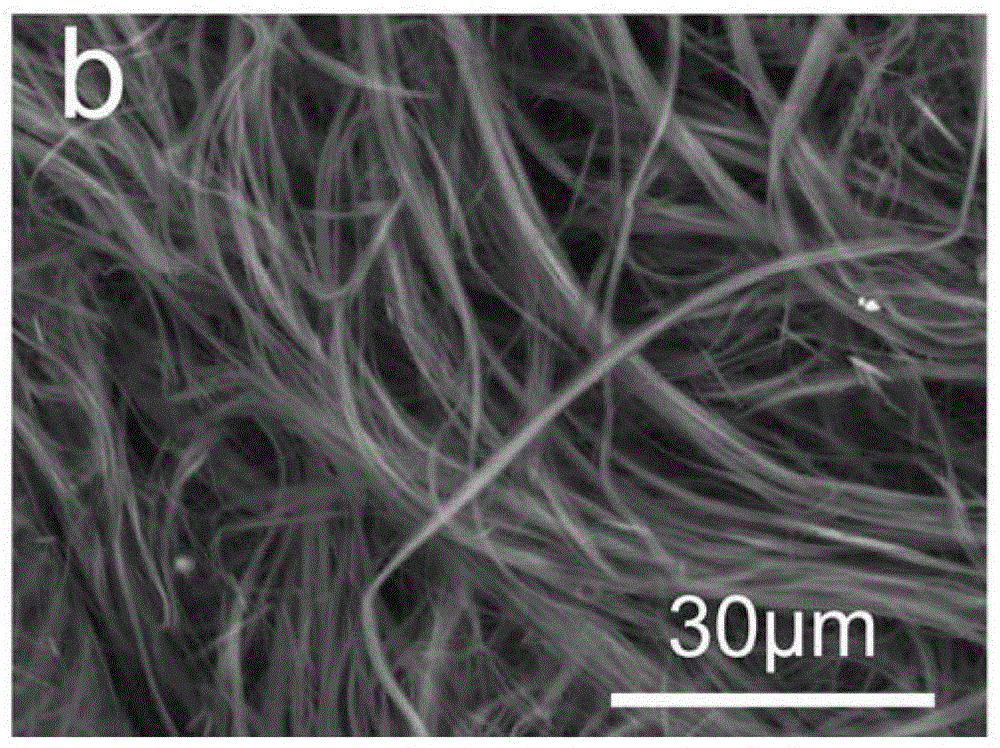

[0042] Embodiment 1 Preparation of hydroxyapatite ultra-long nanowires

[0043] At room temperature, respectively, 0.1760g CaCl 2 , 0.3480g NaH 2 PO 4 , Dissolve 0.700g NaOH in 10mL deionized water. Mix 9mL deionized water, 4mL methanol, and 7mL oleic acid for 30min under magnetic stirring, then add 10mL CaCl dropwise 2 solution, 10mL NaOH solution, 10mL NaH 2 PO 4 The solution was stirred for 30 min. Then transfer the mixed solution to a 100mL reaction kettle, seal it, react at 180°C for 24h, and cool it down to room temperature naturally. The aqueous suspension of long nanowires had a pH close to 7.4 and was then stored at 4°C. Finally, hydroxyapatite ultralong nanowires are obtained, such as Figure 1a with 1b shown.

Embodiment 2

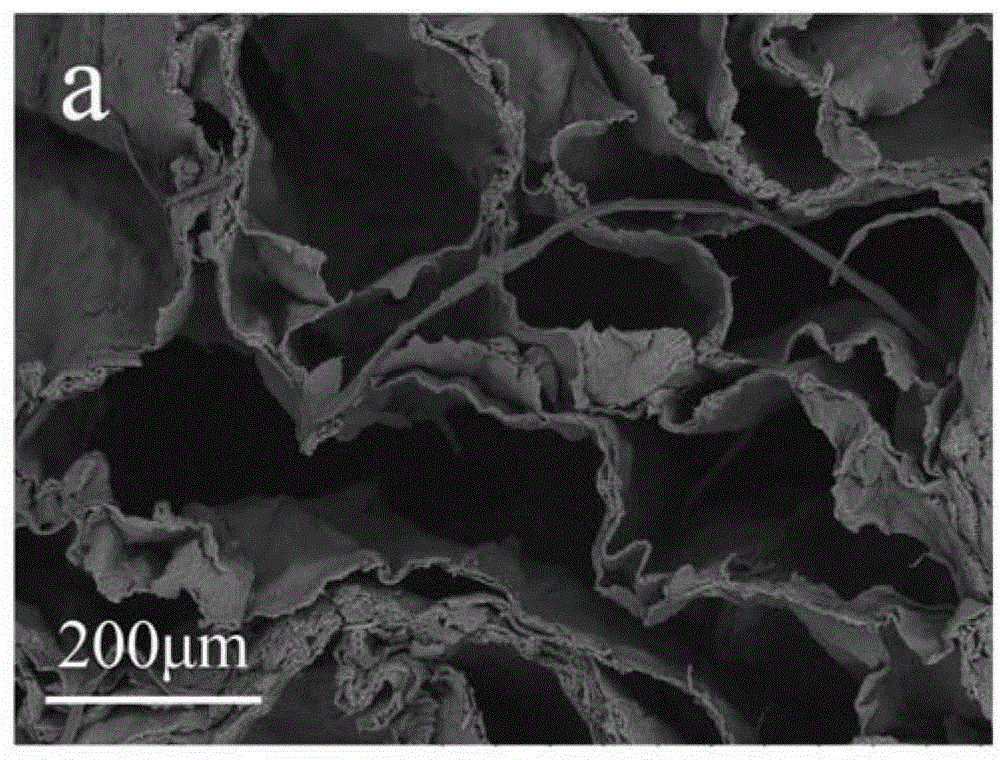

[0044] Embodiment 2 (pure calcium alginate hydrogel)

[0045] At room temperature, 2.0000g CaCl 2 Dissolve in 100 ml of deionized water, dissolve 0.2000 g of sodium alginate in 10 ml of water, and stir at room temperature for 90 min to fully dissolve the sodium alginate. Afterwards, the sodium alginate solution was transferred to a mold of a certain shape, and a water-soluble calcium salt solution was sprayed on it to form a gel. After the gel was formed, the mold and the composite hydrogel in it were immersed in CaCl at 37°C. 2 In the aqueous solution for 12h, the calcium ions diffuse evenly in the composite hydrogel. The internal pore diameter of the pure calcium alginate hydrogel is 200-500 μm, and the internal pore diameter of the pure calcium alginate hydrogel is connected. Its maximum tensile strength is 0.086MPa, tensile Young's modulus is 0.162MPa, maximum compressive strength is 0.061MPa, and compressive modulus E 50% is 0.075MPa.

Embodiment 3

[0047] At room temperature, 2.0000g CaCl 2 Dissolve in 100ml deionized water, dissolve 0.2000g sodium alginate in 10ml deionized water containing 0.0400g hydroxyapatite ultra-long nanowires, stir at room temperature for 90min to fully dissolve sodium alginate, and mix with hydroxyapatite Stone ultra-long nanowires are mixed evenly. The sodium alginate solution is then transferred to a shaped mold on which CaCl is sprayed 2 The aqueous solution makes it gel, and after the gel is formed, the mold and the composite hydrogel in it are immersed in CaCl at 37°C 2 In the aqueous solution for 12h, the calcium ions diffuse evenly in the composite hydrogel. The maximum tensile strength of the alginate / hydroxyapatite ultra-long nanowire composite hydrogel is 0.137MPa, the tensile Young's modulus is 0.253MPa, the maximum compressive strength is 0.090MPa, and the compressive modulus E 50% is 0.089MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compression modulus | aaaaa | aaaaa |

| Maximum tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com