Tea wine brewing process

A technology of tea wine and craftsmanship, applied in the field of wine brewing, can solve problems such as insufficient taste, single taste of tea wine, and limited effectiveness of tea functional components, so as to achieve rich drinking choices and needs, good taste, and improve the body's immunity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

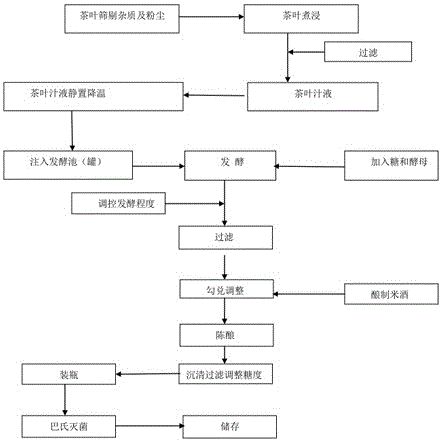

Image

Examples

Embodiment 1

[0036] A tea wine brewing process is characterized in that it comprises the following steps:

[0037] (a) Tea sieve to remove impurities and dust: spread the freshly collected green tea leaves in the air, spread the fresh green tea leaves evenly in a cool and dry place with air circulation, the thickness of the air is 8cm, the temperature of the air is 25°C, and the air is aired. The time is controlled at 10 hours, and the frying pot is used to kill the greens. The temperature of the bottom of the pot is controlled at 120-130 ° C, and then washed with cold water, drained and chopped the tea leaves;

[0038] (b) Extraction of tea juice: Put the tea leaves in boiling water that has been filtered and is suitable for drinking according to the ratio of 0.5%. The tea juice is extracted, and the tea juice is mixed three times, and filtered to remove residues. Finally, 0.5 % of tea juice;

[0039] (c) Leave the tea juice to cool down: the obtained tea juice is poured into the ferment...

Embodiment 2

[0048] A kind of tea wine brewing process is characterized in that comprising the steps:

[0049] (a) Tea sieve to remove impurities and dust: spread the freshly collected black tea leaves, and evenly spread the fresh green tea leaves in a cool and dry place with good air circulation, with a thickness of 10cm and a temperature of 23°C. The time is controlled at 12 hours, and the greening is done with a drum fixing machine, and the temperature is controlled at 110-120°C, then washed with cold water, drained and chopped for tea leaves;

[0050](b) Extraction of tea juice: Put the tea leaves in boiling water that has been filtered and is suitable for drinking according to the ratio of 0.6%, to extract the tea juice, and mix the tea juice after three times, filter and remove the slag, and finally obtain 0.4 -0.7% tea juice;

[0051] (c) Leave the tea juice to cool down: the obtained tea juice is poured into the fermentation tank to cool down, and enters fermentation when the temp...

Embodiment 3

[0060] A kind of tea wine brewing process is characterized in that comprising the steps:

[0061] (a) Tea sieve to remove impurities and dust: spread the freshly collected black tea leaves, spread the fresh green tea evenly in a cool and dry place with good air circulation, the thickness of the spread is 8cm, the temperature of the spread is 25°C, The airing time is controlled at 10 hours, and the greening machine is used to kill greens, and the temperature is controlled at 60-70°C, and then washed with cold water, drained and chopped the tea leaves;

[0062] (b) Extraction of tea juice: Put the tea leaves in boiling water that has been filtered and is suitable for drinking according to the ratio of 0.6%, to extract the tea juice, and mix the tea juice after three times, filter and remove the slag, and finally obtain 0.4 -0.7% tea juice;

[0063] (c) Leave the tea juice to cool down: the obtained tea juice is poured into the fermentation tank to cool down, and enters fermenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com