Method for preparing high-performance PTFE fiber paper

A technology of polytetrafluoroethylene and high-performance fibers, which is applied in fiber types, fiber processing, textiles and papermaking, etc., can solve the problems of high energy consumption and many processes, and achieve low energy consumption, short process, chemical corrosion resistance and flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of polytetrafluoroethylene high-performance fiber paper, the specific steps are:

[0026] (1) Treat the polytetrafluoroethylene fiber with an antistatic agent:

[0027] The PTFE fiber was sprayed with 0.5% potassium phosphate monoester antistatic agent (TF-481) solution by weight, and was allowed to stand for 24 hours at a temperature of 20±1° C. and a humidity of 65±2%.

[0028] (2) After the PTFE fiber treated with antistatic agent is opened, it is fed into the roller carding machine and evenly laid into a fiber web, with a gram weight of 70g / m2. 2 , and hot-rolling the fiber web for 60 s under the conditions of a hot-rolling temperature of 360° C. and a pressure of 30 MPa to obtain a polytetrafluoroethylene high-performance fiber paper. The results of thermogravimetric analysis showed that the fiber paper began to decompose at 508 ° C, showing good thermal stability; the limiting oxygen index of the fiber paper was measured to be 95%, showing ex...

Embodiment 2

[0030] A preparation method of polytetrafluoroethylene high-performance fiber paper, the specific steps are:

[0031] (1) Treat the polytetrafluoroethylene fiber with an antistatic agent:

[0032] The PTFE fiber was sprayed with 0.5% potassium phosphate monoester antistatic agent (TF-481) solution by weight, and was allowed to stand for 24 hours at a temperature of 20±1° C. and a humidity of 65±2%.

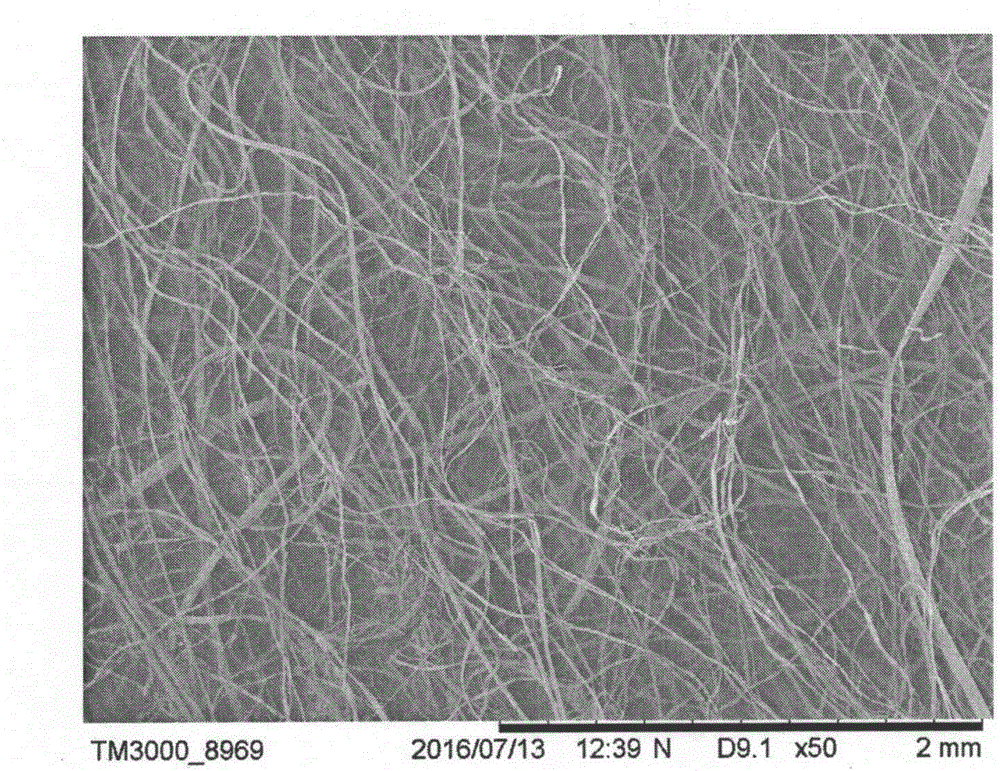

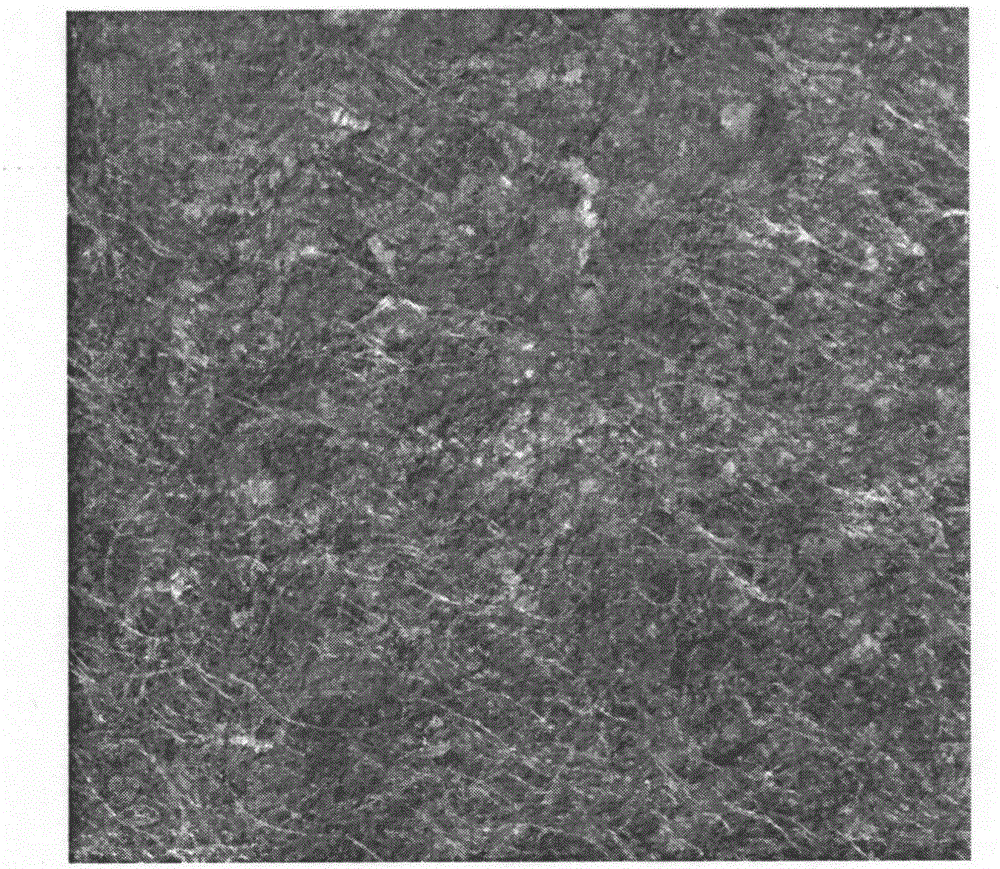

[0033] (2) After the PTFE fiber treated with the antistatic agent is opened, the PTFE and the long-staple cotton fiber are mixed in a weight ratio of 80 / 20 and fed into the roller carding machine to be evenly laid into a fiber web, with a gram weight of 107g per square meter. / m 2 , the form see figure 1 . The fiber web is hot-rolled for 70s at a hot-rolling temperature of 375°C and a pressure of 30MPa to obtain PTFE high-performance fiber paper, such as figure 2 As shown, the surface is black because the cotton fibers are carbonized at high temperature. The results of therm...

Embodiment 3

[0035] A preparation method of polytetrafluoroethylene high-performance fiber paper, the specific steps are:

[0036] (1) Treat the polytetrafluoroethylene fiber with an antistatic agent:

[0037] The PTFE fiber was sprayed with a cationic antistatic agent (SN) solution with a weight concentration of 0.5%, and was allowed to stand for 24 hours at a temperature of 20±1° C. and a humidity of 65±2%.

[0038] (2) After the PTFE fiber treated with antistatic agent is loosened, PTFE and water-soluble vinylon fiber are mixed in a weight ratio of 80 / 20 and fed into a roller carding machine to be evenly laid into a fiber web, with a gram weight of 150g per square meter. / m 2 . The fiber web was soaked in hot water to remove water-soluble vinylon fibers, and then hot-rolled for 90 s under the conditions of a hot rolling temperature of 380° C. and a pressure of 50 MPa to obtain a polytetrafluoroethylene high-performance fiber paper. The results of thermogravimetric analysis showed tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap