Strontium-calcium-codoped lanthanum manganate-based perovskite material, and applications thereof in SOFC

A technology of perovskite material, lanthanum manganate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of strontium calcium co-doped lanthanum manganate-based perovskite material La 0.1 Sr x Ca 0.9-x MnO 3-δ , x=0.1, the steps include:

[0032] (1) Weighing according to the chemical formula, using lanthanum nitrate, calcium nitrate, strontium nitrate and manganese nitrate as precursors, the preparation concentration is 0.1-3mol L -1 precursor mixed solution.

[0033] (2) Add dropwise an aqueous solution of sodium carbonate with a stoichiometric ratio of 1.1-2 to the above precursor solution, keep the solution in a stirring state during the dropwise addition, continue stirring for 0.5-8h after the dropwise addition, and then let stand for 0.5-20h.

[0034] (3) Suction filtration and washing until the pH is 7-9, drying the obtained precipitate at 50-200° C. for 1-10 h, and then calcining at 700° C. for 4 h to obtain a calcined powder.

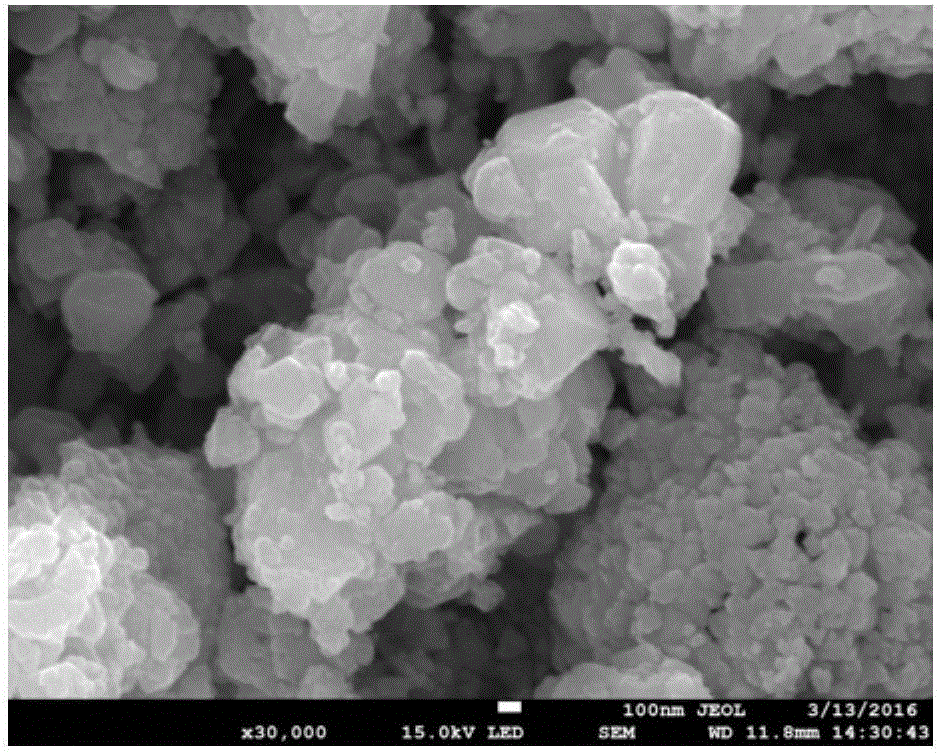

[0035] The resulting material looks like figure 1 As shown, the structure is as Figure 4 shown.

Embodiment 2

[0037] Preparation of strontium calcium co-doped lanthanum manganate-based perovskite material La 0.1 Sr x Ca 0.9-x MnO 3-δ , x=0.3, the steps include:

[0038] (1) Weighing according to the chemical formula, using lanthanum nitrate, calcium nitrate, strontium nitrate and manganese nitrate as precursors, the preparation concentration is 0.1-3mol L -1 precursor mixed solution.

[0039] (2) Add dropwise an aqueous solution of sodium carbonate with a stoichiometric ratio of 1.1-2 to the above precursor solution, keep the solution in a stirring state during the dropwise addition, continue stirring for 0.5-8h after the dropwise addition, and then let stand for 0.5-20h.

[0040] (3) Suction filtration and cleaning until the pH is 7-9, drying the obtained precipitate at 50-200° C. for 1-10 hours, and then calcining at 800° C. for 4 hours to obtain a calcined powder.

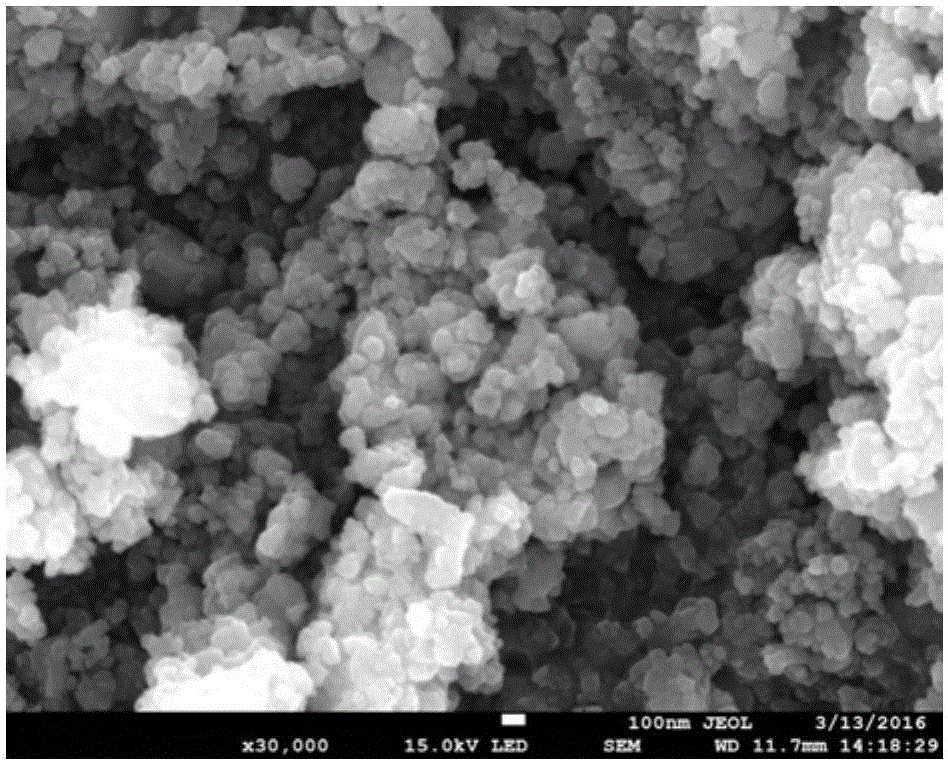

[0041] The resulting material looks like figure 2As shown, the structure is as Figure 4 shown.

Embodiment 3

[0043] Preparation of strontium-doped lanthanum manganate-based perovskite materials La 0.1 Sr x Ca 0.9-x MnO 3-δ , x=0.5, the steps include:

[0044] (1) Weighing according to the chemical formula, using lanthanum nitrate, calcium nitrate, strontium nitrate and manganese nitrate as precursors, the preparation concentration is 0.1-3mol L -1 precursor mixed solution.

[0045] (2) Add dropwise an aqueous sodium carbonate solution with a stoichiometric ratio of 1.1-2 to the above precursor solution, keep the solution in a stirring state during the dropwise addition, continue stirring for 0.5-8h after the dropwise addition, and then let stand for 0.5-20h.

[0046] (3) Suction filtration and washing until the pH is 7-9, drying the obtained precipitate at 50-200° C. for 1-10 h, and then calcining at 1000° C. for 6 h to obtain a calcined powder.

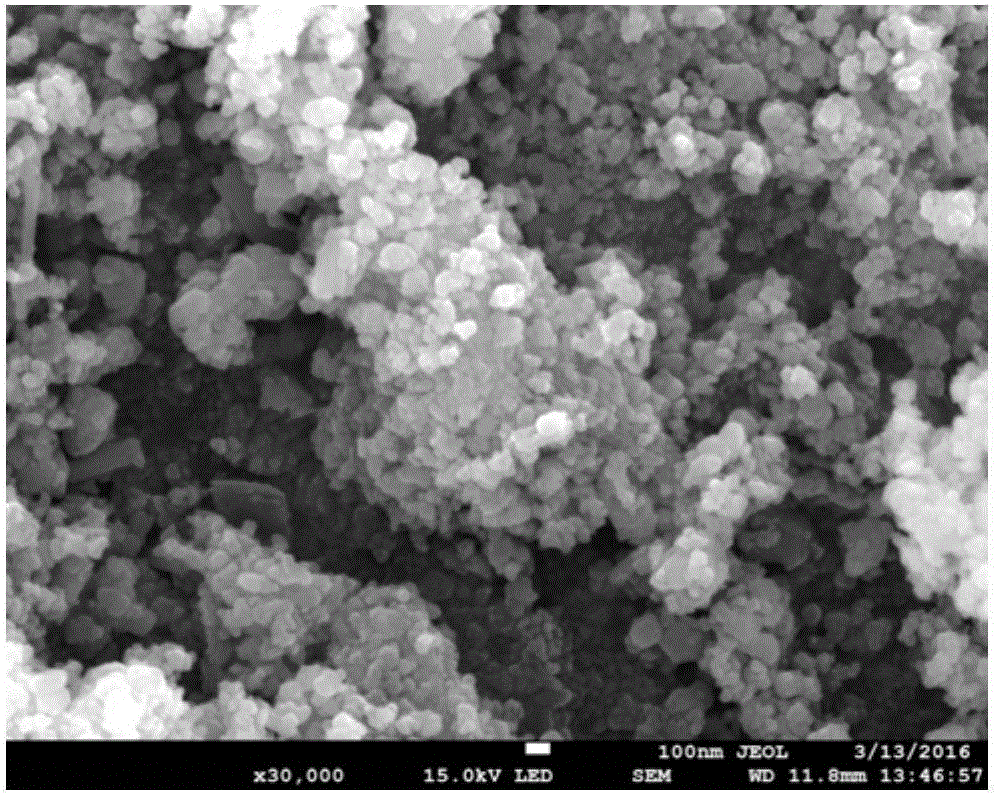

[0047] The resulting material looks like image 3 As shown, the structure is as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com