Application of zinc in preparation of bone or joint restoration regeneration material

A technology for repairing regeneration, joints, applied in the field of chemistry to achieve easy-to-obtain results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

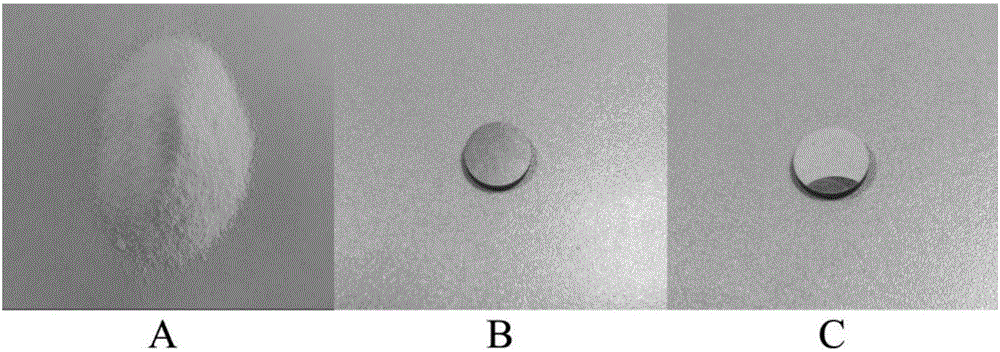

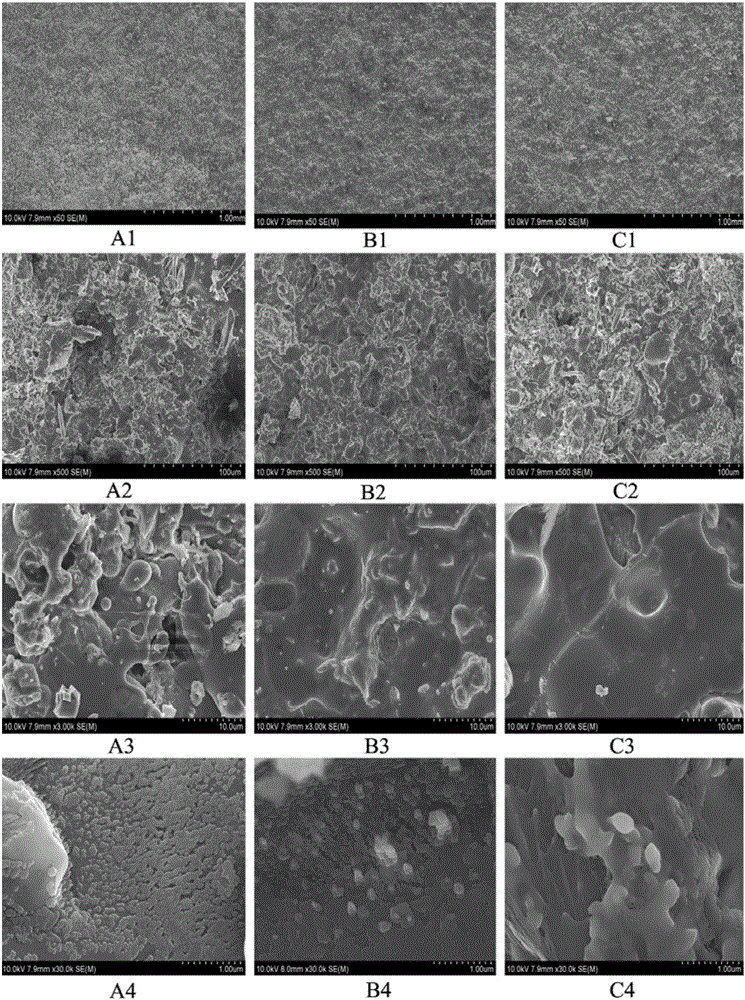

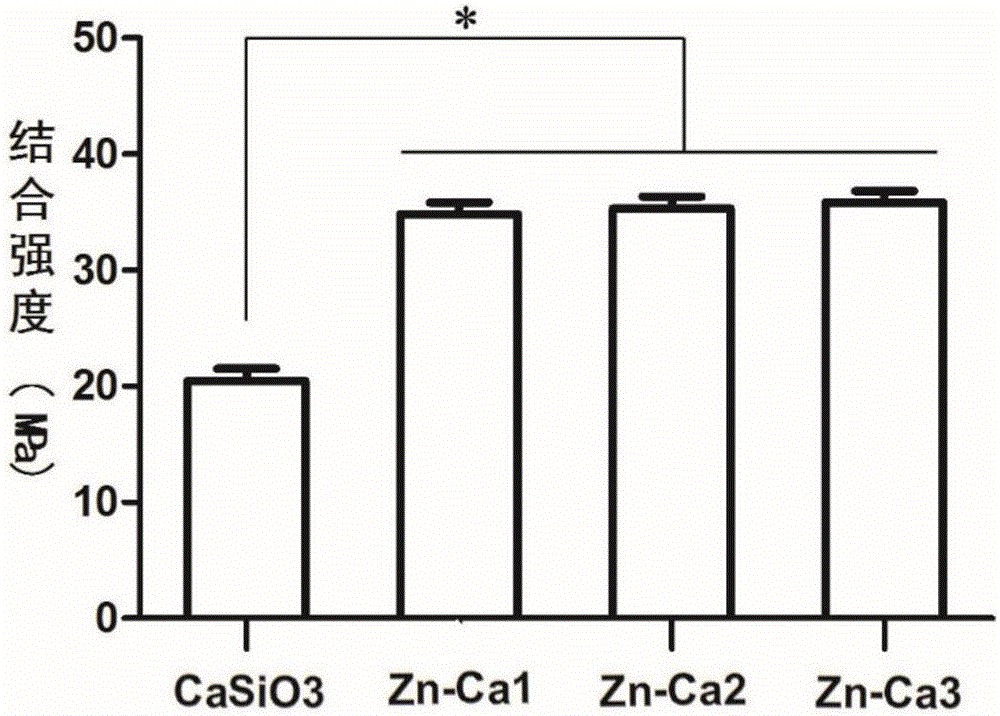

[0028] The present invention proposes an application of zinc in the preparation of bone or joint repair regeneration materials. The zinc-modified calcium silicate coating is prepared from tetraethyl orthosilicate, zinc nitrate and calcium nitrate, and the zinc-modified calcium silicate The paint is coated on the surface of the bone or joint repair regeneration material to form a zinc-modified calcium silicate coating, and is co-cultured with the BMSCs in the bone or joint repair material.

[0029] The molar ratio of zinc to calcium in the zinc-modified calcium silicate is 0.3.

[0030] The BMSCs are BMSCs in the logarithmic growth phase of the fourth generation.

[0031] The molar ratio of zinc to calcium in the zinc-modified calcium silicate is 1:0.1:1, 1:0.3:1 or 1:0.5:1.

[0032] 1. Materials and methods

[0033] (1) Materials

[0034] 1. Experimental materials and instruments

[0035] Titanium alloy sheet, CaSiO 3 Ceramic-coated titanium sheet, zinc-modified calcium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com