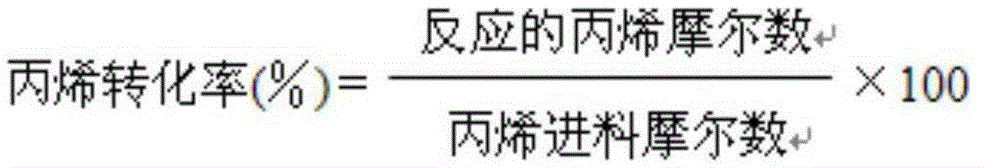

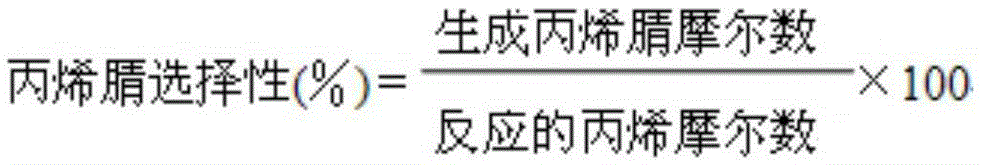

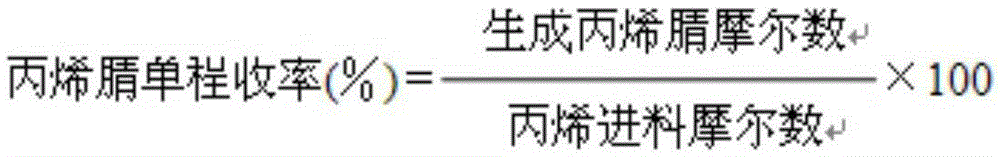

High selectivity catalyst for production of acrylonitrile by propylene ammoxidation

An acrylonitrile catalyst, high-selectivity technology, applied in the preparation of hydrocarbon ammoxidation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the low operating load conditions, low reaction pressure, etc. problem, to achieve the effect of reducing the yield and promoting the conversion of propylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 0.3 gram of sodium hydroxide and 3.6 gram of potassium hydroxide add 11 grams of water and dissolve after heating, obtain material I; 748.7 gram of ammonium heptamolybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in 800 grams of hot water at 80°C to obtain material II; 145.0 grams of bismuth nitrate Bi(NO 3 ) 3 ·5H 2 O, 49.8 grams of 50wt% manganese nitrate solution, 619.8 grams of nickel nitrate Ni (NO 3 ) 2 ·6H 2 O, 373.1 grams of iron nitrate Fe (NO 3 ) 3 9H 2 O, 135.2 grams of magnesium nitrate Mg (NO 3 ) 2 2H 2 O, 8.3 grams of calcium nitrate Ca(NO 3 ) 2 4H 2 O, 71.1 grams of chromium nitrate Cr (NO 3 ) 3 9H 2 O mixed, add 340 grams of water, heat and dissolve as material III; take by weighing 137.5 grams of neodymium nitrate Nd (NO 3 ) 3 ·6H 2 After O was dissolved in 30 grams of water, material IV was obtained.

[0058] Mix material I with 2500 grams of silica sol with a weight concentration of 40%, add materials II, III and IV in turn unde...

Embodiment 2

[0061] 6.07 grams of rubidium nitrate and 4.2 grams of potassium hydroxide add 15 grams of water and dissolve after heating to obtain material I; 877.1 grams of ammonium heptamolybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in 900 grams of hot water at 80°C to obtain material II; 199.8 grams of bismuth nitrate Bi(NO 3 ) 3 ·5H 2 O, 145.9 grams of 50wt% manganese nitrate solution, 181.5 grams of nickel nitrate Ni (NO 3 ) 2 ·6H 2 O, 16.8 grams of iron nitrate Fe (NO 3 ) 3 9H 2 O, 71.8 grams of anhydrous ammonium metatungstate (NH 4 ) 6 h 2 W 12 o 40 and 83.3 grams of chromium nitrate Cr (NO 3 ) 3 9H 2 O mixed, add 340 grams of water, heat and dissolve as material III; take by weighing 89.5 grams of neodymium nitrate Nd (NO 3 ) 3 ·6H 2 After O was dissolved in 15 grams of water, material IV was obtained.

[0062] Mix material I with 2500 grams of silica sol with a weight concentration of 40%, add materials II, III and IV in turn under stirring, and obtain a...

Embodiment 3

[0065] 0.9 gram of sodium hydroxide and 6.6 gram of cesium nitrate add 11 grams of water and dissolve after heating, obtain material I; 479.4 gram of ammonium heptamolybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in 500 grams of 80°C hot water to obtain material II; 131.1 grams of bismuth nitrate Bi(NO 3 ) 3 ·5H 2 O, 264.6 grams of nickel nitrate Ni (NO 3 ) 2 ·6H 2 O, 284.8 grams of iron nitrate Fe (NO 3 ) 3 9H 2 O, 52.0 grams of magnesium nitrate Mg (NO 3 ) 2 2H 2 O, 27.9 grams niobium oxalate Nb 2 (C 2 o 4 ) 5 Mix, add 240 grams of water, heat and dissolve as material III; take by weighing 14.7 grams of neodymium nitrate Nd (NO 3 ) 3 ·6H 2 After O was dissolved in 15 grams of water, material IV was obtained.

[0066] Mix material I with 3500 grams of silica sol with a weight concentration of 40%, add materials II, III and IV in turn under stirring, and obtain a slurry after fully stirring, and put the prepared slurry in a spray dryer according to the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com