Method for preparing spherical silicon dioxide fine powder high in insulation property

A spherical silicon dioxide, high insulating technology, applied in the directions of silicon dioxide, silicon oxide, energy input, etc., can solve the problems of affecting the insulation of fillers, affecting the heat resistance and electrical properties of downstream products, and achieving low production costs , good insulation, low ion content and pH effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

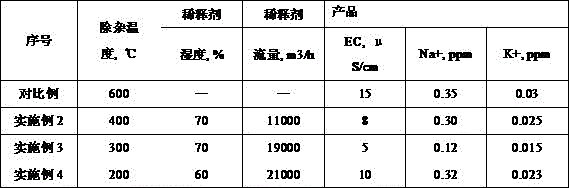

Examples

Embodiment 1

[0024] Embodiment 1, a kind of preparation method of high insulation spherical silica powder, comprises combustion furnace and classifier, is connected with induced draft fan on the classifier, is provided with between the discharge port of combustion furnace and the feed port of classifier. Conveying pipeline, said conveying pipeline is provided with a humidifying device for increasing the humidity in the pipeline, and a diluent air inlet is provided on the conveying pipeline behind the humidifying device; the preparation steps are as follows:

[0025] (1) Raw materials: Silica micropowder with a purity of more than 99.8% is used as the raw material. The conductivity EC of the raw material is less than 0.5 μS / cm, and the Na + / K + Less than 0.5ppm;

[0026] (2) Combustion: Oxygen is used as the carrier gas, natural gas is used as the combustible gas, and oxygen is used as the combustion aid. Under the protection of the carrier gas, the raw materials are added to the combusti...

Embodiment 2

[0029] Embodiment 2, a kind of preparation method of high insulation spherical silica powder, comprises combustion furnace and classifier, is connected with induced draft fan on the classifier, is provided with between the discharge port of combustion furnace and the feed port of classifier. Conveying pipeline, through the induced draft fan, the powder is sucked out from the combustion furnace and enters the classifier through the conveying pipeline for collection. The conveying pipeline is provided with a humidifying device for increasing the humidity in the pipeline, and a diluent air inlet is provided on the conveying pipeline behind the humidifying device; the preparation steps are as follows:

[0030] (1) Raw material: Silica micropowder with a purity of 99.89% is used as the raw material, and the conductivity EC of the raw material is 0.2μS / cm, Na + 0.39ppm;

[0031] (2) Combustion: Oxygen is used as the carrier gas, natural gas is used as the combustible gas, and oxyge...

Embodiment 3

[0034]Embodiment 3, a kind of preparation method of high insulation spherical silica powder, comprises combustion furnace and classifier, is connected with induced draft fan on the classifier, is provided with between the discharge port of combustion furnace and the feed port of classifier. Conveying pipeline, through the induced draft fan, the powder is sucked out from the combustion furnace and enters the classifier through the conveying pipeline for collection. The conveying pipeline is provided with a humidifying device for increasing the humidity in the pipeline, and a diluent air inlet is provided on the conveying pipeline behind the humidifying device; the preparation steps are as follows:

[0035] (1) Raw material: Silica micropowder with a purity of 99.89% is used as the raw material, and the conductivity EC of the raw material is 0.2μS / cm, Na + 0.39ppm;

[0036] (2) Combustion: Oxygen is used as the carrier gas, natural gas is used as the combustible gas, and oxygen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com