High-strength highly-permeable inorganic concrete and preparation method thereof

A concrete and inorganic technology, which is applied in the field of high-strength and high-permeability inorganic concrete and its preparation, can solve the problems that hinder the development and application of permeable concrete, the incompatibility between water permeability and strength, and it is difficult to apply to the main structure, so as to improve the strength and increase the Density, increase strength and toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

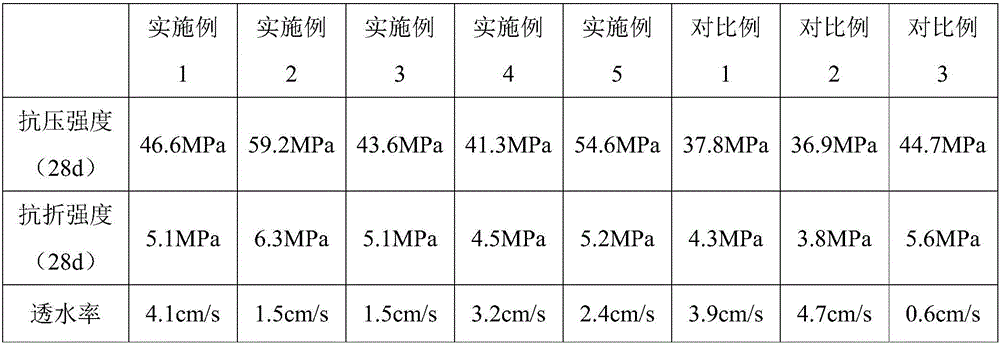

[0026] The high-strength and high-permeability inorganic concrete described in Examples 1 to 5 mainly includes water, cement, steel slag, quartz sand, mineral powder, water reducer, and reinforcing material. Each component in the embodiment is as shown in Table 1 in parts by weight.

[0027] The high-strength and high-permeability inorganic concrete described in Comparative Examples 1 to 3 mainly includes water, cement, steel slag, quartz sand, mineral powder, water reducing agent, and reinforcing material. Each component in the comparative example is also shown in Table 1 in parts by weight. In the comparative example, the amount of reinforcing agent and the proportion of aggregate steel slag and quartz sand were mainly changed.

[0028] Table 1

[0029]

[0030] In Table 1, the cement is ordinary Portland cement with a strength grade of 42.5, the 3d compressive strength is 24.3MPa, and the 28d compressive strength is 45.6MPa; the steel slag is 5-16mm continuous graded s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com