Feeding method and system of acetone cyanohydrin during the preparation of methyl methacrylate

A technology of methyl methacrylate and acetone cyanohydrin, which is applied in the field of feeding methods and systems in the preparation process of methyl methacrylate, can solve the problem of overheating of the droplet surface, increased consumption of acetone cyanohydrin, decomposition of acetone cyanohydrin, etc. problems, to achieve the effect of reducing the degree of decomposition, improving the conversion rate and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

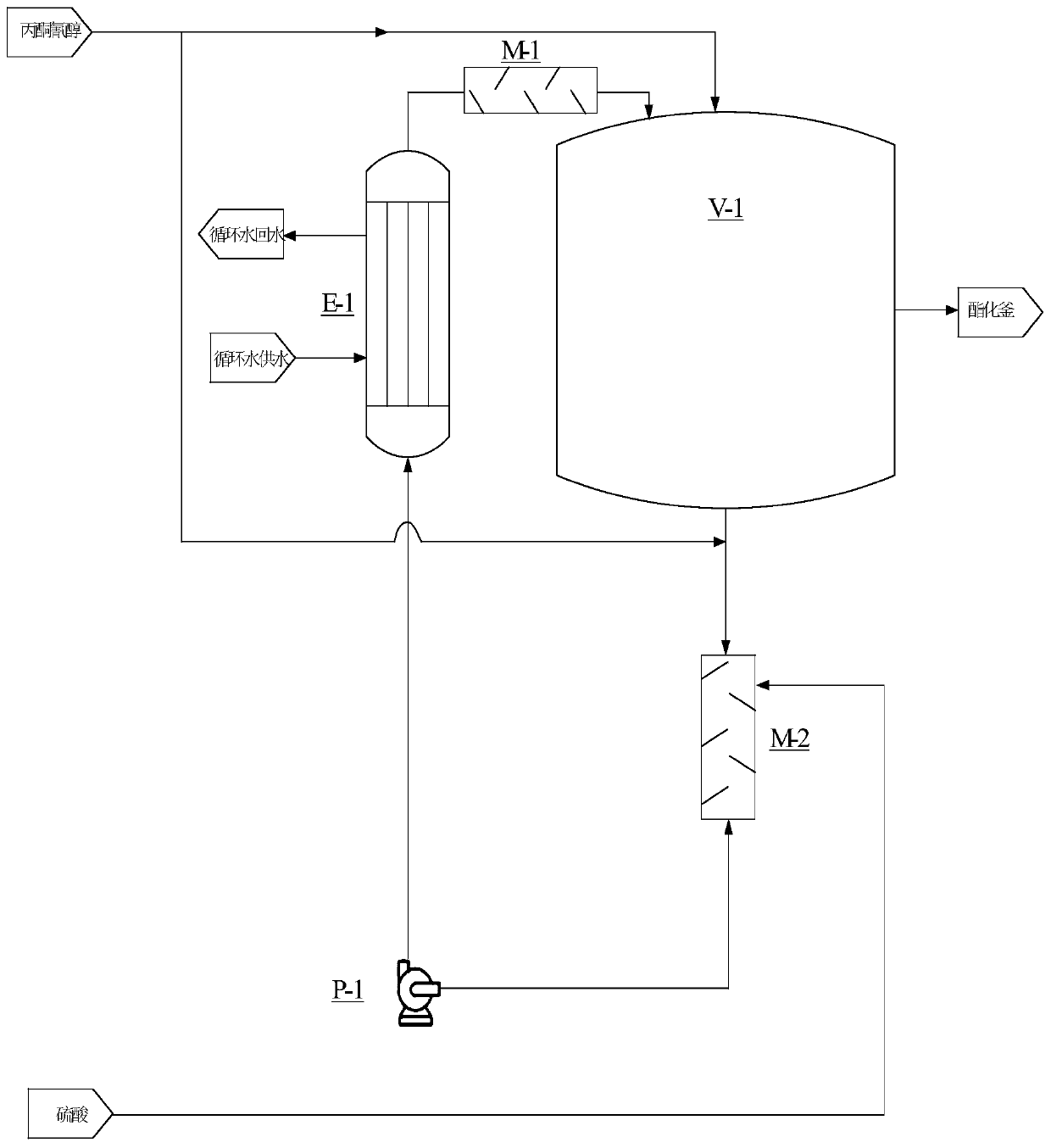

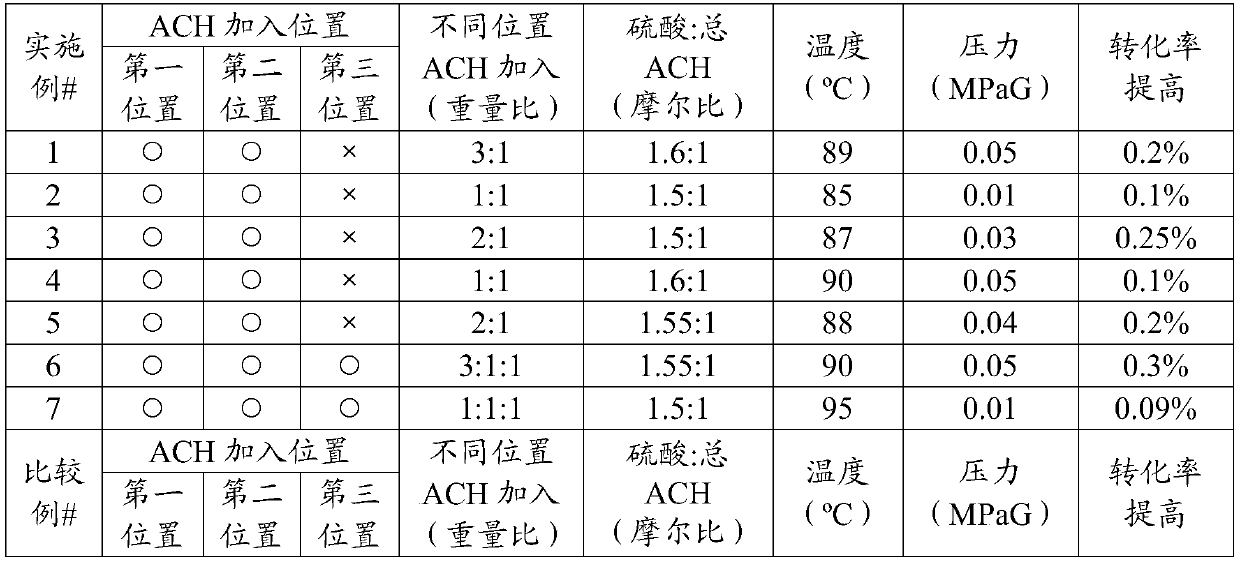

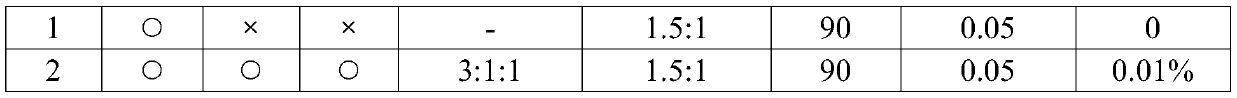

[0035] Concentrated sulfuric acid is continuously added to the amide recycle loop through sulfuric acid mixer M-2. Afterwards, inject acetone cyanohydrin into acetone cyanohydrin in spray mode in two streams at two positions, wherein one stream of acetone cyanohydrin is continuously added in the amide circulation loop by the first acetone cyanohydrin mixer M-1 at the first position, and the other Acetone cyanohydrin is continuously injected into the amide recycle loop through the second acetone cyanohydrin injector J-1. Wherein the first acetone cyanohydrin mixer M-1 is arranged on the pipeline between the outlet of the amide cooler E1 and the inlet of the gas separator V1. The weight ratio of the acetone cyanohydrin passed through the first acetone cyanohydrin mixer M-1 and the acetone cyanohydrin injected through the second acetone cyanohydrin injector J-1 is 3:1. The molar ratio of concentrated sulfuric acid injected into the amide loop to the total amount of acetone cyano...

Embodiment 2

[0038] Concentrated sulfuric acid is continuously added to the amide recycle loop via sulfuric acid mixer M-2. Afterwards, inject acetone cyanohydrin into acetone cyanohydrin in spray mode in two streams at two positions, wherein one stream of acetone cyanohydrin is continuously added in the amide circulation loop by the first acetone cyanohydrin mixer M-1 positioned at the first position, and the other Acetone cyanohydrin is continuously injected into the amide recycle loop through the second acetone cyanohydrin injector J-1. Wherein the first acetone cyanohydrin mixer M-1 is arranged on the pipeline between the outlet of the amide cooler and the inlet of the gas separator. The weight ratio of the acetone cyanohydrin passed through the first acetone cyanohydrin mixer M-1 and the acetone cyanohydrin injected through the second acetone cyanohydrin injector J-1 is 1:1. The molar ratio of concentrated sulfuric acid injected into the amide loop to the total amount of acetone cyan...

Embodiment 3

[0041] Concentrated sulfuric acid is continuously added to the amide recycle loop via sulfuric acid mixer M-2. Afterwards, inject acetone cyanohydrin into acetone cyanohydrin in spray mode in two streams at two positions, wherein one stream of acetone cyanohydrin is continuously added in the amide circulation loop by the first acetone cyanohydrin mixer M-1 positioned at the first position, and the other Acetone cyanohydrin is continuously injected into the amide recycle loop through the second acetone cyanohydrin injector J-1. Wherein the first acetone cyanohydrin mixer M-1 is arranged on the pipeline between the outlet of the amide cooler E-1 and the inlet of the gas separator V1. The weight ratio of the acetone cyanohydrin passed through the first acetone cyanohydrin mixer M-1 and the acetone cyanohydrin injected through the second acetone cyanohydrin injector J1 is 2:1. The molar ratio of concentrated sulfuric acid injected into the amide loop to the total amount of aceton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com