Fluorescent metal-organic framework porous material and preparation method

A metal-organic framework and porous material technology, which is applied in the field of fluorescent metal-organic framework porous materials and its preparation, achieves the effects of high yield, simple reaction conditions, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Dissolve sodium 1,2-dihydroxybenzene-3,5-disulfonate (1 mmol) in 10 mL of water, and dissolve strontium nitrate (1 mmol) in 10 mL of water to form a uniform solution. Mix the two solutions, stir them evenly, place them in a polytetrafluoroethylene-lined reaction kettle, heat them up to 130°C for 4 days, then lower the temperature to room temperature, filter, and wash the solids once with deionized water and ethanol, respectively. Dry to give a solid.

Embodiment 2

[0029] Weigh 1,2-dihydroxybenzene-3,5-disulfonate sodium (2mmol) and dissolve it in 20mL water, and dissolve strontium nitrate (2mmol) in 20mL water to form a uniform solution. Mix the two solutions, stir them evenly, place them in a polytetrafluoroethylene-lined reactor, heat up to 140°C for 5 days, then cool down to room temperature, filter, and wash the solid once with deionized water and ethanol, respectively. Dry to give a solid.

Embodiment 3

[0031] Weigh 1,2-dihydroxybenzene-3,5-disulfonate sodium (3mmol) and dissolve it in 30mL water, and dissolve strontium nitrate (3mmol) in 30mL water to form a uniform solution. Mix the two solutions, stir them evenly, place them in a polytetrafluoroethylene-lined reaction kettle, heat up to 130°C for 3 days, then lower the temperature to room temperature, filter, and wash the solid once with deionized water and ethanol, respectively. Dry to give a solid.

[0032] The results of this example show that the morphology of the material is as follows: figure 1 , SEM photo

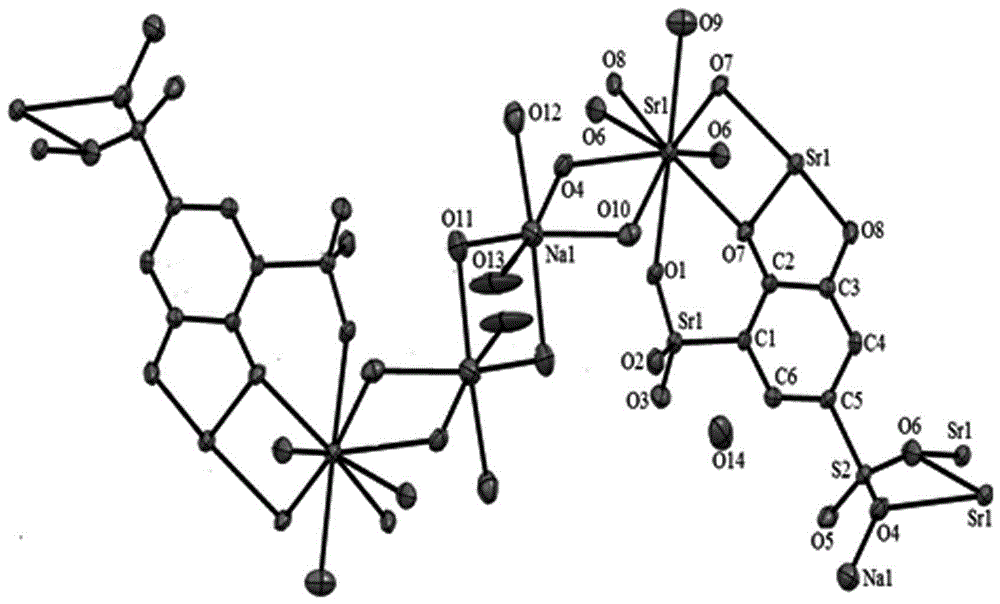

[0033] The molecular structure of embodiment 2 material compound is as figure 2 , single crystal diffraction molecular structure

[0034] The obtained porous material of embodiment 2, experimental result shows, and aperture is 1.03 * 1.03nm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com