Polymer gel particle for profile control and water plugging of deep parts as well as preparation method thereof

A technology of gel particles and deep profile control, which is applied in the direction of drilling compositions, chemical instruments and methods, and can solve the problems of slow expansion and low plugging strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

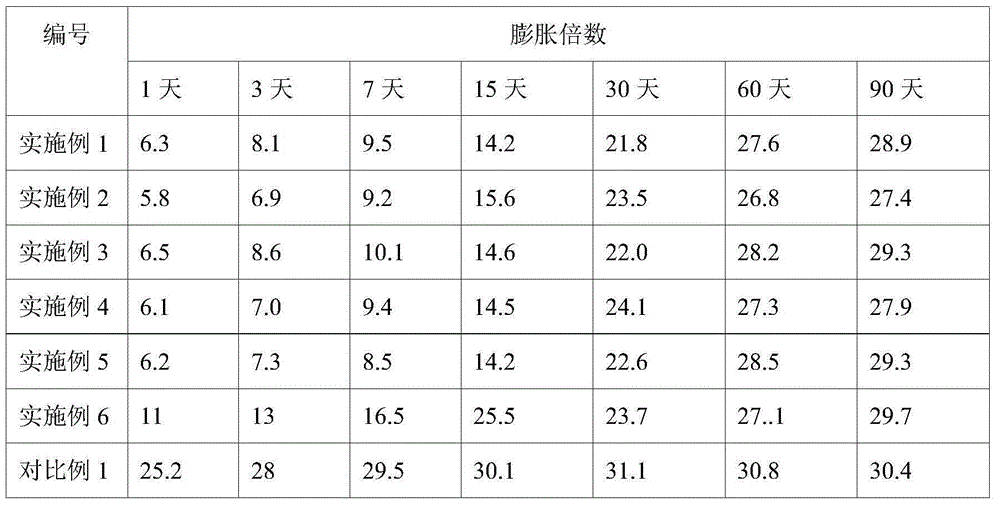

Examples

Embodiment 1

[0036] First add 650g of deionized water to the polymerization kettle, add 100g of acrylamide, 10g of methacrylamide, 1.5g of hydroxymethyl cellulose, 0.001g of N,N'-methylenebisacrylamide, stir until completely dissolved, and use Adjust the pH value to 9 with NaOH, and start to pass high-purity nitrogen gas. After 30 minutes, the temperature in the kettle was lowered to 15°C, and then the free radical polymerization composite initiator system was added, and the nitrogen gas was continued to flow for 30 minutes before sealing. After 1 hour, the reaction temperature was gradually raised to 45°C. After 3 hours of reaction, a water-containing gel-like polymer product was obtained. After cutting the glue, it was blown and dried at 90°C for 1.5 hours, crushed with a pulverizer, and sieved out from microns to millimeters. grade particles to obtain polymer gel particles for deep profile control and water plugging.

[0037] The sample obtained in Example 1 was dispersed in cyclohexane...

Embodiment 2

[0040] First add 650g deionized water to the polymerization kettle, add 100g acrylamide, 60g acrylic acid, 3g hydroxyethyl cellulose, 0.01g polyethylene glycol diacrylate, stir until completely dissolved, adjust the pH value to 9 with NaOH, and Start to pass high-purity nitrogen gas, and after 30 minutes, lower the temperature in the kettle to 15°C, then add a free radical polymerization composite initiator system, continue to pass nitrogen gas for 30 minutes, and then seal it. After 1 hour, the reaction temperature was gradually raised to 45°C. After 3 hours of reaction, a water-containing gel-like polymer product was obtained. After cutting the glue, it was blown and dried at 90°C for 1.5 hours, crushed with a pulverizer, and sieved out from microns to millimeters. grade particles to obtain polymer gel particles for deep profile control and water plugging.

[0041]The sample obtained in Example 2 was dispersed in cyclohexane, stirred for 1 hour, and its particle size was mea...

Embodiment 3

[0044] First add 650g of deionized water to the polymerization kettle, add 100g of acrylamide, 40g of methacryloyloxyethyl trimethylammonium chloride, 6g of hydroxymethyl cellulose, 0.1g of N,N'-m-phenylene bisma Stir the imide until it is completely dissolved, adjust the pH value to 9 with NaOH, and start feeding high-purity nitrogen gas. After 30 minutes, lower the temperature in the kettle to 15°C, then add the free radical polymerization composite initiator system, and continue nitrogen gas flow Seal after 30 minutes. After 1 hour, the reaction temperature was gradually raised to 45°C. After 3 hours of reaction, a water-containing gel-like polymer product was obtained. After cutting the glue, it was blown and dried at 90°C for 1.5 hours, crushed with a pulverizer, and sieved out from microns to millimeters. grade particles to obtain polymer gel particles for deep profile control and water plugging.

[0045] The sample obtained in Example 3 was dispersed in cyclohexane, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com