Multi-element toughened and modified special material for PP-R pipe and preparation method thereof

A special material for pipes, toughening modification technology, applied in the field of polymer materials, can solve the problems of limited scope of application, prone to brittle fracture, and can not really improve the comprehensive performance of PP-R pipes, so as to achieve comprehensive performance improvement, Improvement of interface performance, improvement of rigidity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The embodiment of the present invention also provides a method for preparing a multi-component toughened modified PP-R pipe special material, which includes the following steps:

[0033] A), prepare toughening agent I, toughening agent II and inorganic rigid particles:

[0034] a1) Preparation of toughening agent I: select TMB series compounds, CHB-5 compounds, NU-100 compounds and NAB compounds, rare earth β nucleating agents as WGB series compounds, organic acid β nucleating agents as DCHT compounds, One or more of hydrazine diacid and suberic acid are used as β-nucleating agent, fully pre-mixed with PP-R resin in proportion, and then the pre-mixed material is placed in a twin-screw extrusion granulator for Blend molding, cooling, and pelletizing to obtain the toughening agent I, which is set aside.

[0035] Among them, the sufficient premixing of the β-nucleating agent and PP-R resin means that the β-nucleating agent is uniformly dispersed in the PP-R material by us...

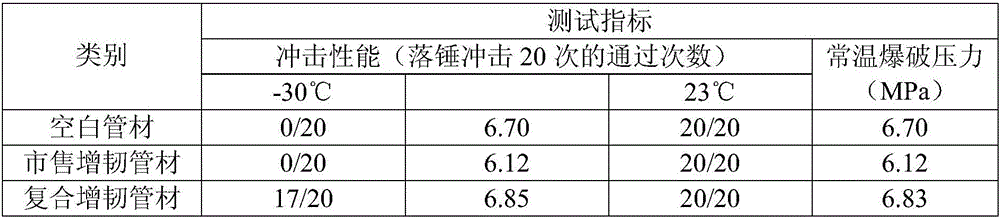

Embodiment 1

[0043] A multi-component toughened and modified PP-R pipe special material, the raw material unit is 55-95 parts of PP-R resin, 2-20 parts of toughening agent I, and 1-20 parts of toughening agent II. 5 parts, 2 to 20 parts of inorganic rigid particles, the raw materials are configured within the range.

[0044] The PP-R resin is random copolymerized polypropylene, brand: PA14-D, PetroChina Daqing Oilfield Co., Ltd. (the PP-R resins described below are all resins of this brand), and the content is 78 parts.

[0045] Toughening agent I content is 2 parts, and its composition is PP-R resin and β nucleating agent. Based on 100 parts by weight of the toughening agent I, wherein, the content of PP-R resin is 95 parts, and the beta nucleating agent is an aromatic amide compound (TMB) with a content of 5 parts. Trademark: TMB-5, Shanxi Chemical Industry graduate School.

[0046] The content of toughening agent II is 10 parts, and its composition is PP-R resin, elastomer and compati...

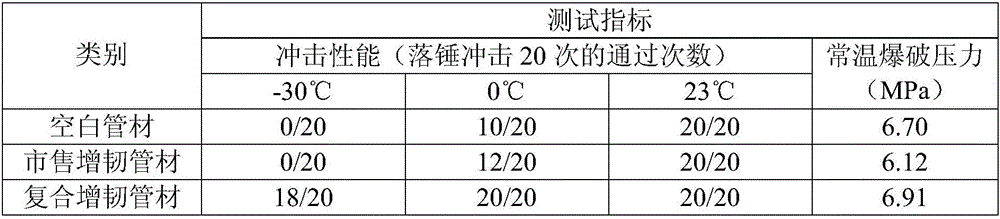

Embodiment 2

[0054] A multi-component toughening modified PP-R pipe special material, the raw material unit is 55-95 parts of PP-R resin, 1-5 parts of toughening agent I, and 2-5 parts of toughening agent II. 20 parts, inorganic rigid particles are 2 to 20 parts, and the raw materials are configured within the range.

[0055] PP-R resin is random copolymerized polypropylene with a content of 83 parts.

[0056] Toughening agent I content is 2 parts, and its composition is PP-R resin and nucleating agent. Based on 100 parts by weight of toughening agent I, wherein, the content of PP-R resin is 95 parts, and the beta nucleating agent is an aromatic amide compound (NAB), with a content of 5 parts. Trademark: NAB-82, Shanxi Chemical Industry graduate School.

[0057] The content of toughening agent II is 5 parts, and its composition is PP-R resin, elastomer and compatibilizer. Based on 100 parts by weight of toughening agent II, wherein, the content of PP-R resin is 80 parts, the elastomer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com