High temperature and corrosion resistant HTV conductive glue and preparation method thereof

A conductive glue, corrosion-resistant technology, applied in conductive adhesives, adhesives, polymer adhesive additives, etc., can solve problems such as endangering human health, falling off of substrates, and inability to serve for a long time, and achieves a simple and easy preparation method. , the effect of strong adhesion, excellent electrical and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A preparation method of high temperature and corrosion resistant HTV conductive glue, comprising the following steps:

[0048] (i) Conductive powder drying

[0049] Bake the conductive powder for 60h-80h;

[0050] (ii) The particle size of the conductive powder is extremely matched

[0051] The dried conductive powder is finely matched in particle size, and the conductive powder with large and small particle sizes are respectively taken according to the weight ratio of 10:1 for pre-mixing;

[0052] (ⅲ) Coating with conductive powder

[0053] Surface treatment of the premixed powder obtained in step (ii) by a wet method to obtain a conductive powder coated with a silane coupling agent;

[0054] (ⅳ) mixed

[0055] Mix the conductive powder coated with silane coupling agent obtained in step (iii) with liquid silicone rubber, heat-resistant additives, catalysts, and cross-linking agents for 10 minutes to 2 minutes to obtain high-temperature-resistant and corrosion-resis...

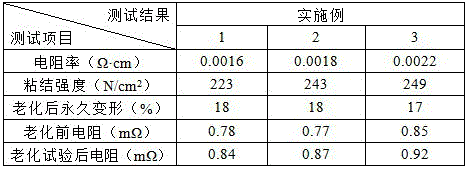

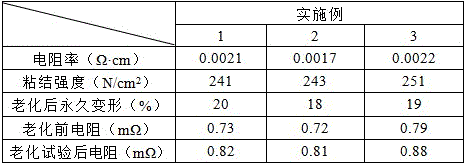

Embodiment 1

[0057] Weigh 75.50 g of pure silver conductive powder with an average particle size of 30 μm and 754.5 g of silver-coated copper conductive powder with an average particle size of 60 μm, and dry the two conductive powders separately for 60 hours, then perform preliminary mixing; use 0.001 g of commercially available silane Coupling agent A-171 uses a wet method to treat the surface of the powder after the extreme matching, so that the surface is coated with a layer of titanate coupling agent; after coating, the powder is put into the double planetary mixer, Add 100g of methyl vinyl trifluoropropyl liquid silicone rubber, 10g of soluble polyferric organosiloxane, 10g of platinum catalyst and 50g of methyl hydrogen silicone oil into the mixer and mix for 10min to obtain RTV-1 type conductive glue.

Embodiment 2

[0059] Weigh 72.72g of pure silver conductive powder with an average particle size of 30μm and 727.2g of silver-coated aluminum conductive powder with an average particle size of 60μm, and dry the two conductive powders separately for 70h, then perform preliminary mixing; use 0.0025g of commercially available silane Coupling agent A-174 uses a wet method to treat the surface of the powder after the extreme matching, so that the surface is coated with a layer of titanate coupling agent; the coated powder is put into a double planetary mixer, and simultaneously Add 125g of methylvinyltrifluoropropyl liquid silicone rubber, 20g of soluble polyferric organosiloxane, 15g of platinum catalyst and 40g of methyl hydrogen silicone oil into the mixer and mix for 20min to obtain RTV-1 type conductive glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com