Coated positive electrode material of lithium-ion battery and preparation method of positive electrode material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as the inability to remove residual lithium on the surface and the inability to reduce the pH value of materials, and achieve the effects of environmental friendliness, safe and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

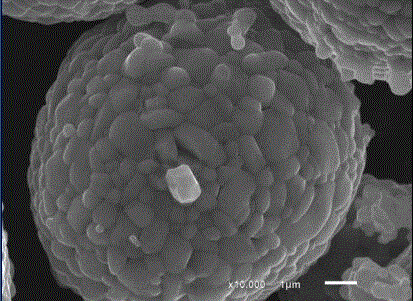

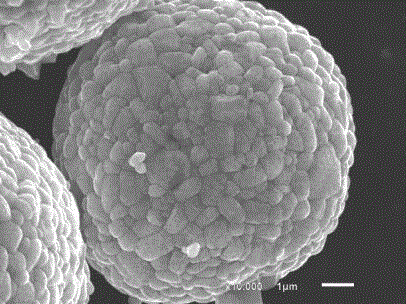

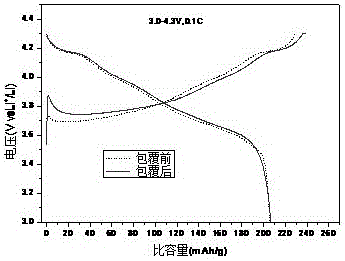

[0034] A kind of coating type lithium ion battery cathode material of the present invention, its matrix material is high-nickel cathode active material LiNi 0.89 co 0.08 al 0.03 o 2 , the surface of the base material has a uniform coating, the coating is alumina, and the coating accounts for 0.38% of the mass of the base material; the mass of the lithium element of the residual lithium salt on the surface of the base material accounts for 0.256% of the total mass of the base material %, after coating, the mass of lithium element of residual lithium salt in the positive electrode material of the coated lithium ion battery accounts for 0.09% of the total mass of the positive electrode material of the coated lithium ion battery.

[0035] The preparation method of the coated lithium ion battery cathode material of the present embodiment specifically comprises the following steps:

[0036] (1) Fully dissolve the aluminum nitrate weighed according to the stoichiometric ratio in d...

Embodiment 2

[0041] A kind of coating type lithium ion battery cathode material of the present invention, its matrix material is high-nickel cathode active material and is LiNi 0.84 co 0.12 mn 0.04 o 2 , the surface of the matrix material has a uniform coating, the coating is zirconia, and the coating accounts for 0.54% of the mass of the matrix material; the mass of lithium element of the residual lithium salt on the surface of the matrix material accounts for 0.289% of the total mass of the matrix material %, after coating, the mass of lithium element of the residual lithium salt in the positive electrode material of the coated lithium ion battery accounts for 0.082% of the total mass of the positive electrode material of the coated lithium ion battery.

[0042] The preparation method of the coated lithium ion battery cathode material of the present embodiment specifically comprises the following steps:

[0043] (1) Fully dissolve the zirconium nitrate weighed according to the stoichi...

Embodiment 3

[0048] A kind of coating type lithium ion battery cathode material of the present invention, its matrix material is high-nickel cathode active material LiNi 0.93 co 0.05 al 0.02 o 2 , the surface of the base material has a uniform coating, the coating is lithium cobaltate, and the coating accounts for 0.83% of the mass of the base material; the mass of the lithium element of the residual lithium salt on the surface of the base material accounts for 10% of the total mass of the base material 0.342%, after coating, the mass of lithium element of the residual lithium salt in the positive electrode material of the coated lithium ion battery accounts for 0.057% of the total mass of the positive electrode material of the coated lithium ion battery.

[0049] The preparation method of the coated lithium ion battery cathode material of the present embodiment specifically comprises the following steps:

[0050] (1) Fully dissolve the cobalt acetate weighed according to the stoichiome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com